Heat exchanger for frying machine

A technology for heat exchangers and fryers, which is applied in heat storage heaters, fluid heaters, oil/fat baking, etc. It can solve the problems of difficult to meet quality requirements, increase production costs, and oil deterioration, and achieve good results. The effect of prolonging the service life and increasing the relative speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

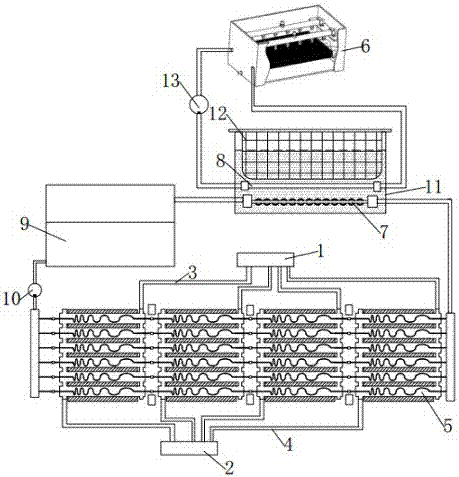

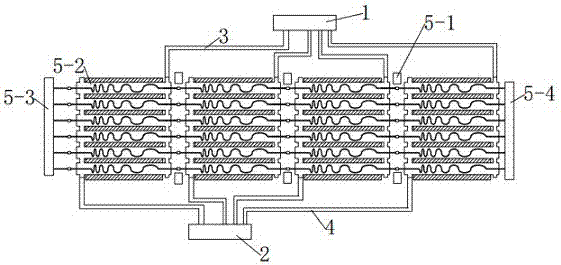

[0037] like figure 1 As shown, a fryer heat exchanger includes a first header 1, a second header 2, a first pipeline 3, a second pipeline 4, a heating heat exchange assembly 5, a cooling heat exchange assembly 6, a heat transfer assembly Heat component 7, cold transfer component 8, heat conduction oil tank 9, hydraulic pump 10 and air pump 13. The hydraulic pump 10 adopts an adjustable flow pump.

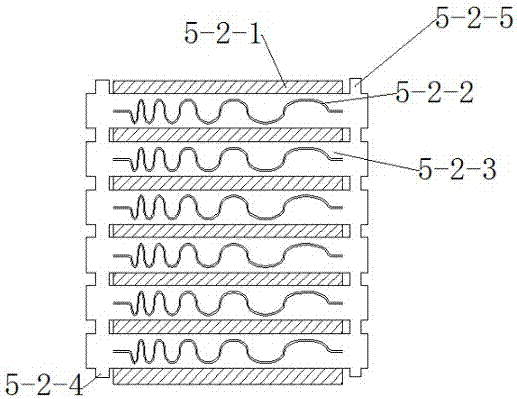

[0038] like figure 1 , 2 As shown in and 3, the heating heat exchange assembly 5 includes a heat insulation plate 5-1, a heat exchanger 5-2, a first collective inlet pipe 5-3 and a first collective outlet pipe 5-4. The heat exchanger 5-2 includes a heat exchange frame 5-2-1, a heat exchange tube 5-2-2 and a heat medium tube 5-2-3. Six heat medium pipes 5-2-3 are fixed on the heat exchange frame 5-2-1 in parallel. The heat medium inflow ends 5-2-5 of the six heat medium pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com