Starting method of SNAD process for treating biogas slurry of pig farm

A pig farm and biogas slurry technology, which is applied in the direction of biological treatment adjustment method, biological treatment device, water treatment parameter control, etc., can solve the problem of less application, and achieve the effect of saving manpower and capital costs, and saving chemical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] One, a kind of start-up method of processing pig farm biogas slurry SNAD process, comprises the following steps:

[0046] (1) Construct a joint-type continuous flow reaction device:

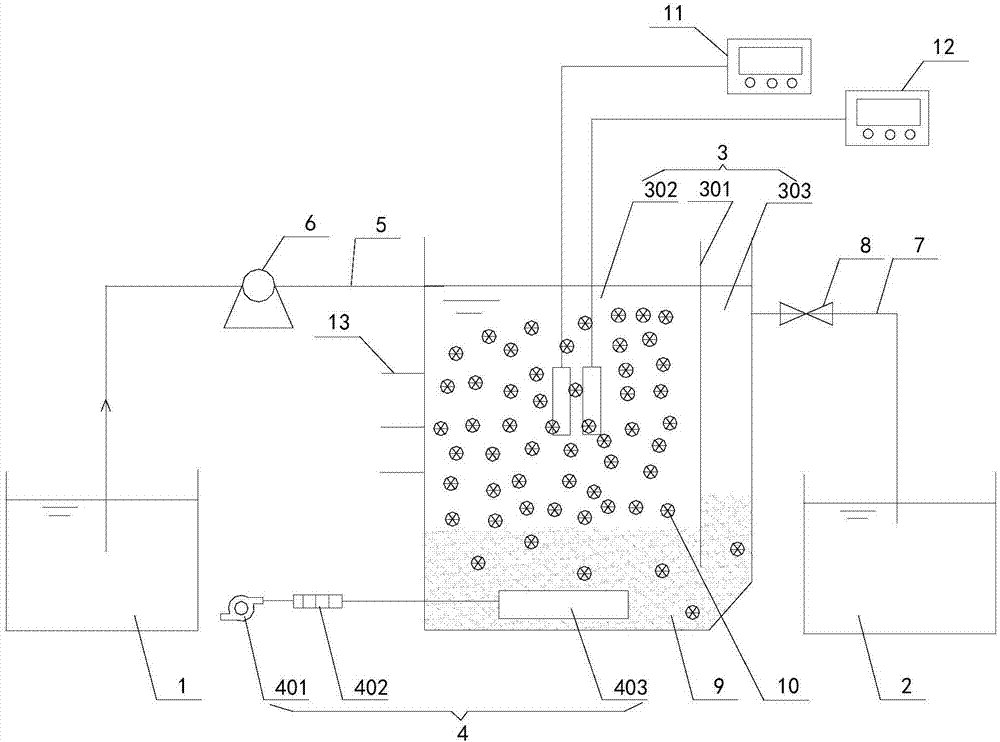

[0047] The combined continuous flow reaction device includes a tank body 3 and an aeration device 4 .

[0048] A partition 301 is arranged inside the tank body 3, and the partition board 301 divides the tank body 3 into a reaction zone 302 and a precipitation zone 303, and the lower parts of the reaction zone 302 and the precipitation zone 303 communicate.

[0049] The upper part of the reaction zone 302 is provided with a water inlet pipe 5 for pig farm biogas slurry to enter, and the upper part of the precipitation zone 303 is provided with an outlet pipe 7; the bottom of the reaction zone 302 and the precipitation zone 303 are inoculated with sludge, and The height of the sludge is higher than the bottom edge of the dividing plate 301; the aeration device 4 includes an aeration pump 40...

Embodiment 2

[0069] One, a kind of start-up method of processing pig farm biogas slurry SNAD process, comprises the following steps:

[0070] (1) Construct a combined continuous flow reaction device (with starting Example 1);

[0071] (2) Construction of sludge-biofilm composite integrated denitrification process:

[0072] Mixing anammox sludge and nitrification sludge with a volume ratio of 5:5 is the inoculation sludge 9; adding inoculation sludge 9 to the co-built continuous flow reaction device in step (1), the inoculation sludge The inoculum amount of mud 9 is 1 / 3 of the effective volume in the reaction zone 302 of the tank body 3, and PVC polyester filler 10 is added at the same time, and the filling rate of the PVC polyester filler 10 is 60%;

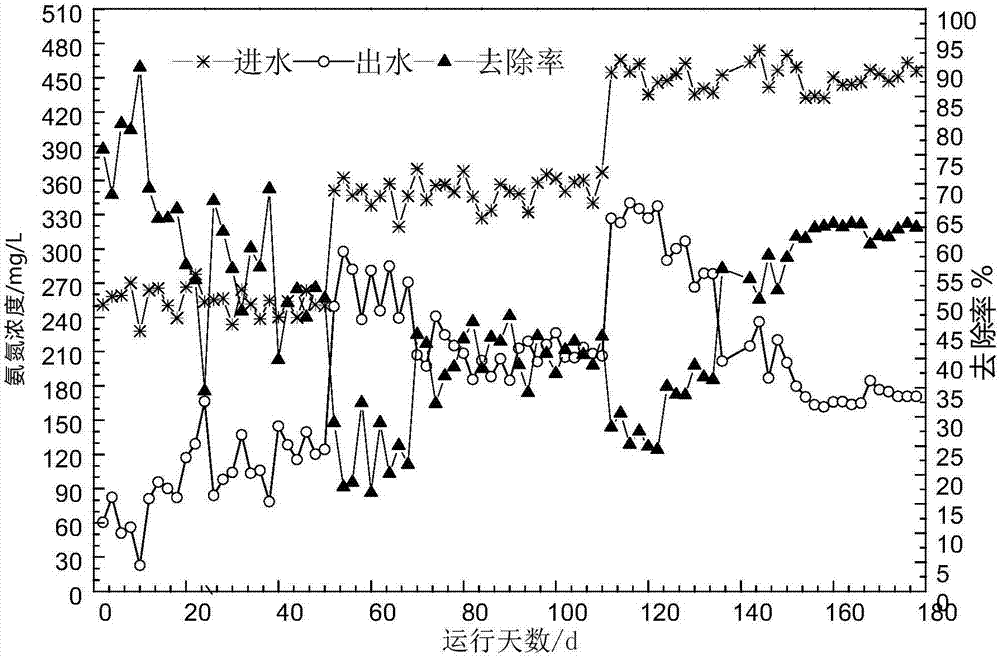

[0073] (3) Startup: Control dissolved oxygen DO at 0.2-0.6mg·L -1 , the hydraulic retention time is controlled at 0.6-1.5d, the temperature is at 26-32°C, the pH of the pig farm biogas slurry influent is 7.5-8.2, and the ammonia nitrogen co...

Embodiment 3

[0084] One, a kind of start-up method of processing pig farm biogas slurry SNAD process, comprises the following steps:

[0085] (1) Construct a combined continuous flow reaction device (with starting Example 1);

[0086] (2) Construction of sludge-biofilm composite integrated denitrification process:

[0087] Mix the anammox sludge and nitrification sludge with a volume ratio of 9:1 to be the inoculation sludge 9; add the inoculation sludge 9 to the co-built continuous flow reaction device in step (1), and the inoculation sludge The inoculum amount of mud 9 is 1 / 5 of the effective volume in the reaction zone 302 of the tank body 3, and PVC polyester filler 10 is added at the same time, and the filling rate of the PVC polyester filler 10 is 30%;

[0088] (3) Startup: Control dissolved oxygen DO at 0.2-0.6mg·L -1 , the hydraulic retention time is controlled at 0.6-1.5d, the temperature is at 26-32°C, the pH of the pig farm biogas slurry influent is 7.5-8.2, and the ammonia ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com