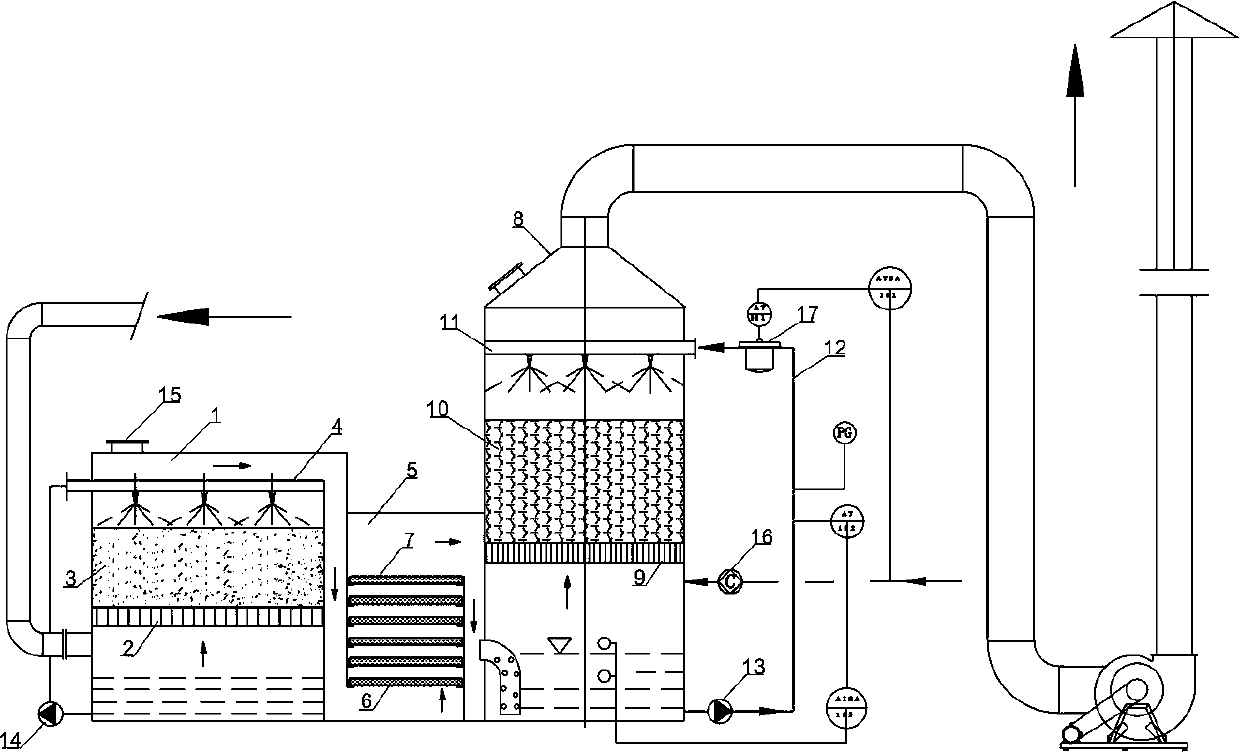

Centralized industrial waste gas treatment system

A centralized treatment and industrial waste gas technology, applied in the direction of gas treatment, air quality improvement, membrane technology, etc., can solve the problems of unstable treatment efficiency and treatment effect, and achieve the effect of unattended

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

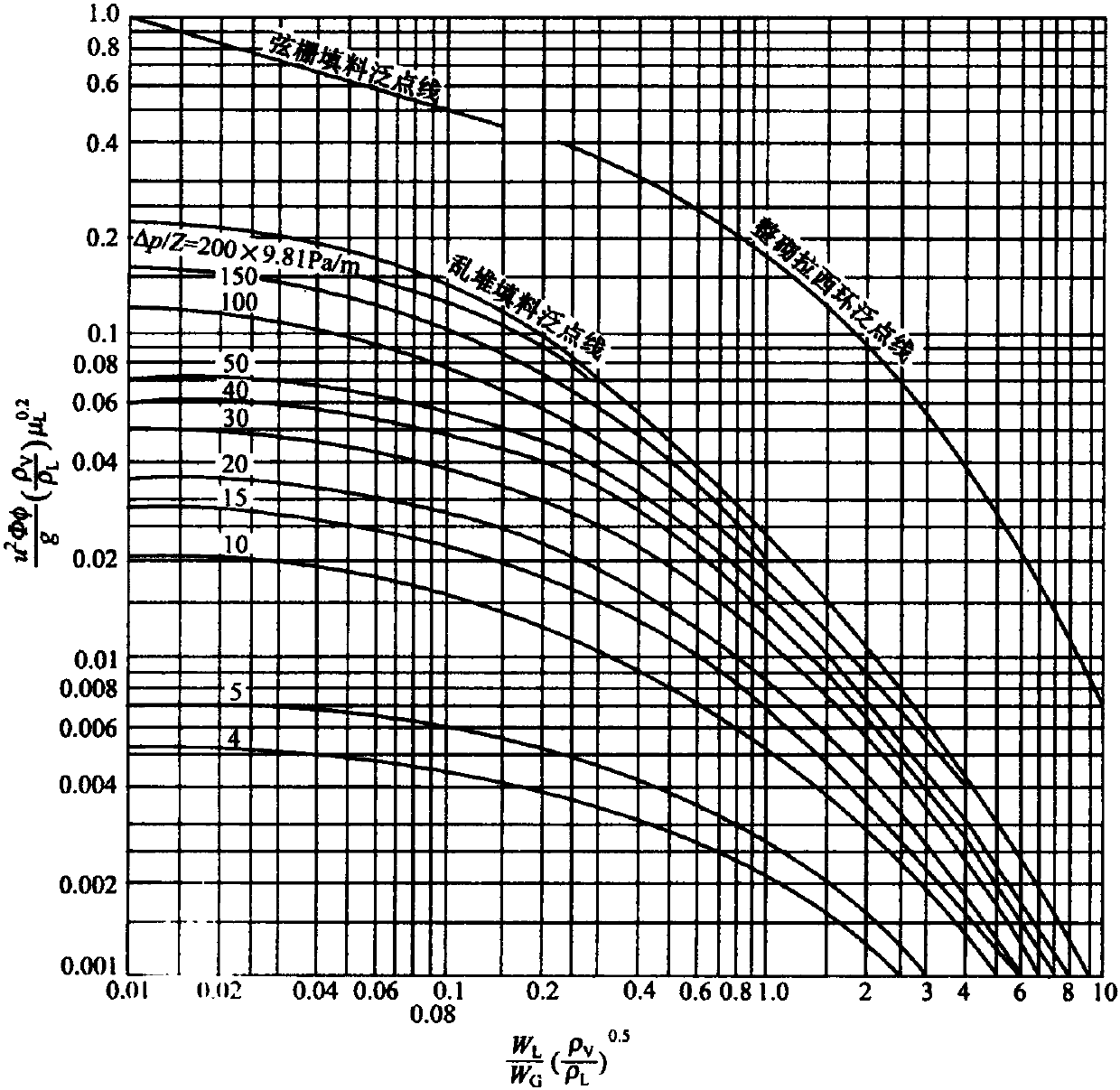

Method used

Image

Examples

preparation example Construction

[0049] The invention also discloses a method for preparing a grid for supporting fillers, the grids are the first grid and the second grid; the manufacturing process includes the following steps:

[0050] (1) There are several positioning points arranged in a circle on the FRP plate, and the positioning points are evenly distributed on the circumference; positioning pins are fixed on the positioning points;

[0051] (2) Fix one end of the glass fiber yarn on a positioning pin, and then carry out circumferential winding, longitudinal winding and horizontal winding respectively, so that the outer edge of the bracket is formed on the circular circumference formed by the positioning pins, and the circular There are several holes inside to form ventilation holes;

[0052] (3) The adhesive is evenly sprayed on the glass fiber yarn, so that the glass fiber yarn is bonded together, then solidified quickly, and the mold is removed after curing; the weight ratio of the amount of adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com