Application of two-dimensional MXene membrane in gas separation

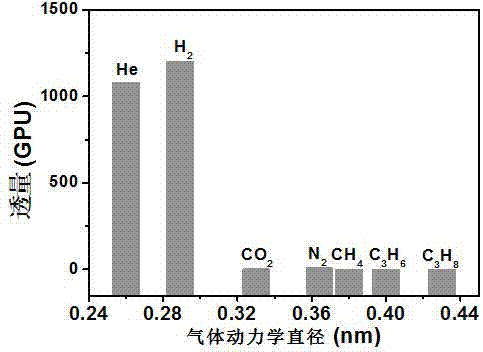

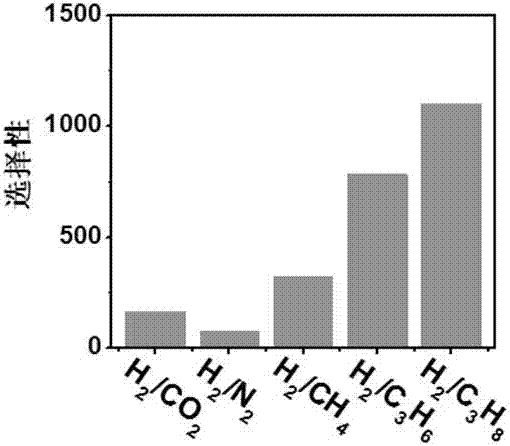

A gas separation and mixed gas technology, applied in semi-permeable membrane separation, hydrogen separation using solid contact, hydrogen separation, etc., can solve the problems of complex preparation process, difficulty in large-scale application, poor thermal stability, etc., and achieve simple preparation process, Reproducible, highly gas-selective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method for a two-dimensional MXene film, comprising the following steps:

[0046] (1) First mix 1g of lithium fluoride with 100ml of hydrochloric acid solution (volume concentration 10%), and then mix 1g of three-dimensional layered Ti 3 AlC 2 The powder was added to the above solution, stirred for 2 h, washed by centrifugation at 1000 rpm, and dried to obtain Ti 3 C 2 powder;

[0047] (2) Add 1g Ti 3 C 2 The powder was mixed with 500 ml ethanol, sonicated for 1 h, and then centrifuged at 500 rpm for 1 h. The obtained supernatant was a solution containing two-dimensional MXene nanosheets with a concentration of 5 mg / ml;

[0048] (3) The above two-dimensional MXene nanosheet solution was deposited on a polyethersulfone filter membrane (PES) substrate with a pore size of 0.5 μm and a diameter of 10 mm by spraying, and dried at 100 ° C for 10 h in a blast drying oven A two-dimensional MXene film can be obtained.

[0049] Application of the two-dimensio...

Embodiment 2

[0052] A preparation method for a two-dimensional MXene film, comprising the following steps:

[0053] (1) First mix 1g lithium bromide with 200ml hydrochloric acid solution (volume concentration 40%), then mix 100g three-dimensional layered Ti 3 AlC 2 The powder was added to the above solution, stirred for 48h, centrifuged and washed at 8000rpm, dried to obtain Ti 3 C 2 powder;

[0054] (2) Add 1g Ti 3 C 2 powder with 2000 ml H 2 O mixed, sonicated for 8h, and then centrifuged at a speed of 5000rpm for 3h, and the resulting supernatant was a solution containing two-dimensional MXene nanosheets with a concentration of 2.5mg / ml;

[0055] (3) The above-mentioned two-dimensional MXene nanosheet solution was deposited on a polyethersulfone filter membrane (PES) substrate with a pore size of 0.5 μm and a diameter of 500 mm by natural drying method, and dried in a vacuum oven at 300 ° C for 48 h A two-dimensional MXene film can be obtained.

[0056] Application of the two-di...

Embodiment 3

[0059] A preparation method for a two-dimensional MXene film, comprising the following steps:

[0060] (1) First mix 1g of lithium bromide with 150ml of nitric acid solution (volume concentration 35%), and then mix 20g of three-dimensional layered Ti 3 AlC 2 The powder was added to the above solution, stirred for 14h, centrifuged and washed at 2000rpm, and dried to obtain Ti 3 C 2 powder;

[0061] (2) Add 5g Ti 3 C 2 The powder was mixed with 500 ml dimethyl sulfoxide, ultrasonicated for 2 hours, and then centrifuged at 5000 rpm for 1 hour. The obtained supernatant was a solution containing two-dimensional MXene nanosheets with a concentration of 0.25 mg / ml;

[0062] (3) The above-mentioned two-dimensional MXene nanosheet solution was deposited on a polyethersulfone filter membrane (PES) substrate with a pore size of 0.5 μm and a diameter of 100 mm by vacuum filtration, and dried in a vacuum oven at 80°C for 12 hours After that, the two-dimensional MXene film can be obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com