Humidity sensor based on TiO2 composite material

A technology of humidity sensor and composite material, which is applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of narrow temperature application range, application limitation, long-term response and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The above TiO 2 The preparation steps of the composite material are as follows:

[0025] Step 1, get natural graphite and concentrated sulfuric acid to mix, stir slowly to make it mix uniformly, obtain the reaction solution that 60ml graphite concentration is 45g / L, then place this reaction solution in an ice bath, mix 6g KMnO 4 Slowly add to the reaction solution, after 2 hours, place the reaction device in a water bath at 40°C, continue to stir for 2 hours, then add 100ml of deionized water dropwise to the reaction solution, and after dilution, raise the temperature of the reaction solution to 95°C and continue the reaction for 15 minutes. Add 280ml of deionized water and 6ml of H to the reaction solution 2 o 2 To terminate the reaction, the khaki product was obtained by centrifugation, washed and centrifuged repeatedly with 1.25mol / L dilute hydrochloric acid and the supernatant was discarded until the supernatant contained SO 4 2- After washing, the obtained khak...

Embodiment 1

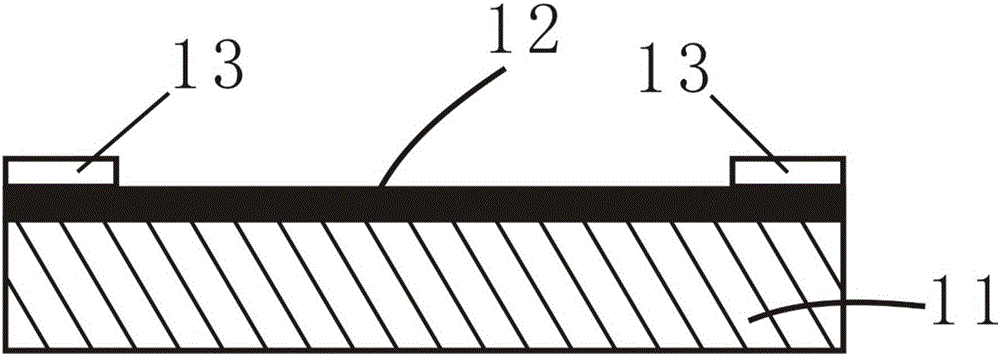

[0030] In this embodiment, a TiO-based 2 A resistive humidity sensor of composite material, the humidity sensor includes a ceramic substrate, TiO coated on the surface of the ceramic substrate 2 Composite material, prepared on TiO 2 Metal counter electrode on composite surface.

[0031] The above TiO 2 The preparation steps of the composite material are as follows:

[0032] Step 1, get natural graphite and concentrated sulfuric acid to mix, stir slowly to make it mix uniformly, obtain the reaction solution that 60ml graphite concentration is 45g / L, then place this reaction solution in an ice bath, mix 6g KMnO 4 Slowly add to the reaction solution, after 2 hours, place the reaction device in a water bath at 40°C, continue to stir for 2 hours, then add 100ml of deionized water dropwise to the reaction solution, and after dilution, raise the temperature of the reaction solution to 95°C and continue the reaction for 15 minutes. Add 280ml of deionized water and 6ml of H to the ...

Embodiment 2

[0040] In this embodiment, a TiO-based 2 A resistive humidity sensor of composite material, the humidity sensor includes a ceramic substrate, TiO coated on the surface of the ceramic substrate 2 Composite material, prepared on TiO 2 Metal counter electrode on composite surface.

[0041] The above TiO 2 The preparation steps of the composite material are as follows:

[0042] Step 1, get natural graphite and concentrated sulfuric acid to mix, stir slowly to make it mix uniformly, obtain the reaction solution that 60ml graphite concentration is 45g / L, then place this reaction solution in an ice bath, mix 6g KMnO 4 Slowly add to the reaction solution, after 2 hours, place the reaction device in a water bath at 40°C, continue to stir for 2 hours, then add 100ml of deionized water dropwise to the reaction solution, and after dilution, raise the temperature of the reaction solution to 95°C and continue the reaction for 15 minutes. Add 280ml of deionized water and 6ml of H to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com