Internal thermal domestic waste pyrolysis system

A domestic waste and internal heating technology, which is applied in the direction of biofuel, special dry distillation, and combustion technology mitigation, can solve the problem of low processing capacity of domestic waste pyrolysis furnaces, improve equipment processing efficiency, reduce operating costs, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

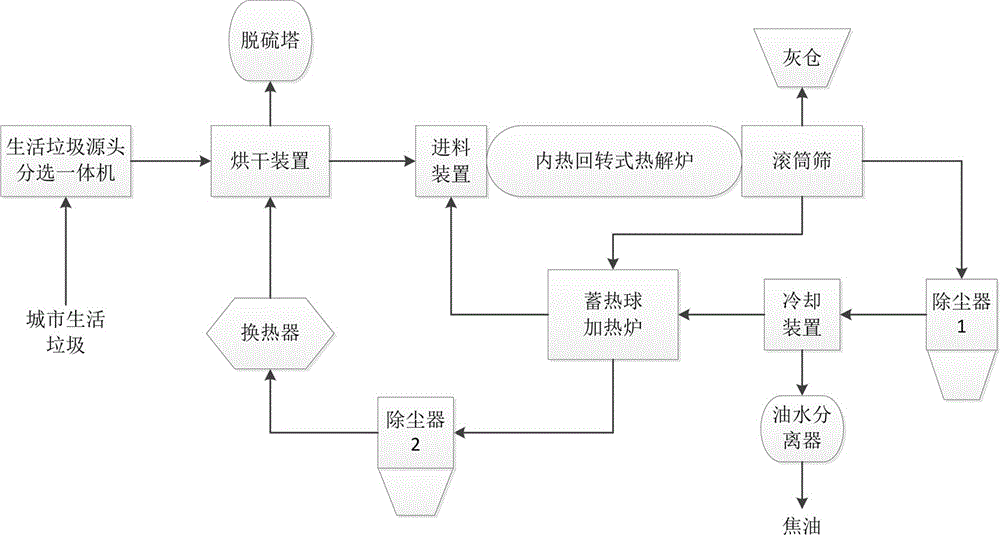

[0025] An internal heating domestic waste pyrolysis system includes a domestic waste source sorting integrated machine, a drying device, a feeding device, an internal heat rotary pyrolysis furnace, a drum screen, a heat storage ball heating furnace, a dust collector 1, a dust collector 2, Cooling device, oil-water separator, heat exchanger, desulfurization tower, ash bin, among which the domestic garbage source sorting integrated machine is connected to the drying device, and the drying device is connected to the garbage feeding port of the feeding device through a screw, and the feeding device There is also a regenerating ball feed port connected to the regenerating ball heating furnace, the feeding device is connected to the inlet of the internal heat rotary pyrolysis furnace, the outlet of the internal heat rotary pyrolysis furnace is connected to the inlet of the drum screen, and the screen of the drum screen The upper object outlet is connected to the feed port of the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com