Method for exploiting high-inclined-angle heavy oil reservoir by plane gravity displacement

A heavy oil reservoir, gravity flooding technology, applied in the direction of fluid production, earthwork drilling, wellbore/well components, etc., to achieve the effects of high oil washing efficiency, high plane sweep coefficient, and improved industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

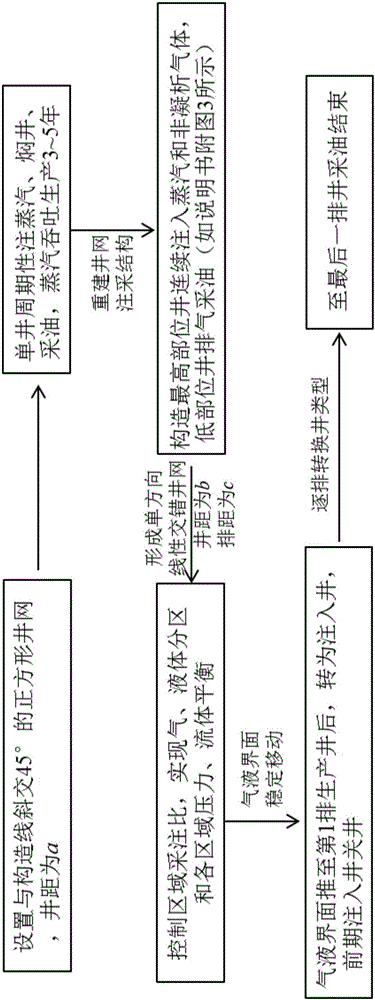

[0030] A method for exploiting high-dip heavy oil reservoirs by planar gravity flooding, such as figure 1 shown, including the following steps:

[0031] Step 1. Select oil reservoir;

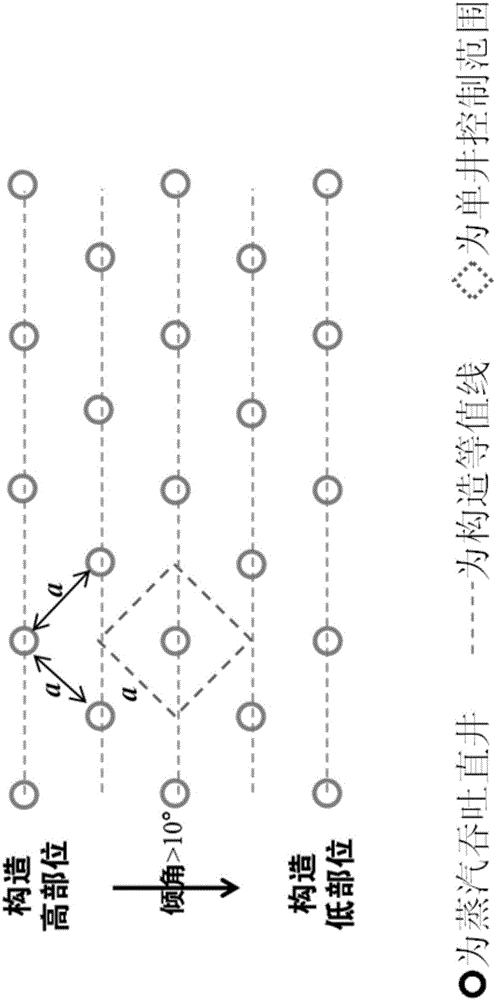

[0032] Step 2, set vertical well square well pattern in the production area of the reservoir for steam huff and puff production, such as figure 2 As shown, the square well pattern of vertical wells contains multiple vertical wells, and multiple vertical wells form multiple well rows, and the adjacent four vertical wells are distributed in a square shape;

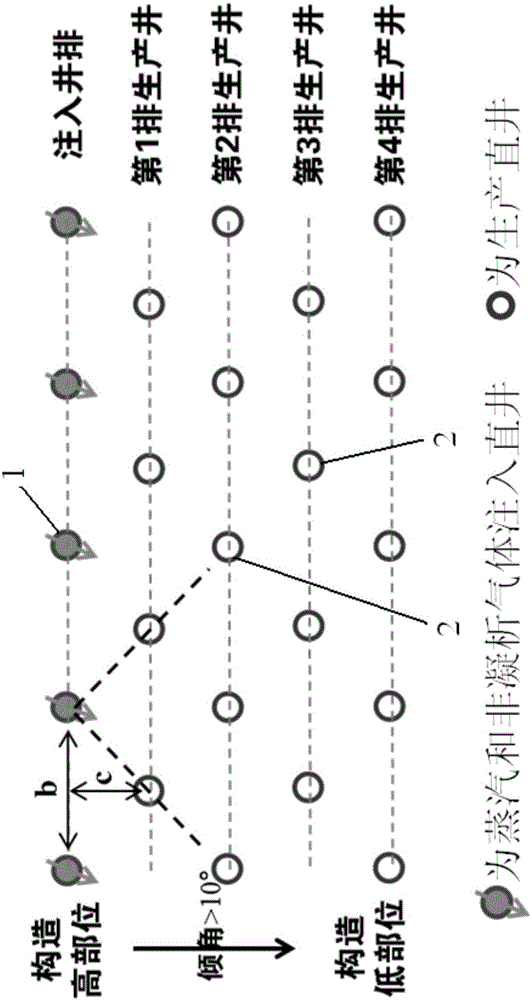

[0033] Step 3. A row of vertical wells located at the highest structural position in the square well pattern of vertical wells is used as injection well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com