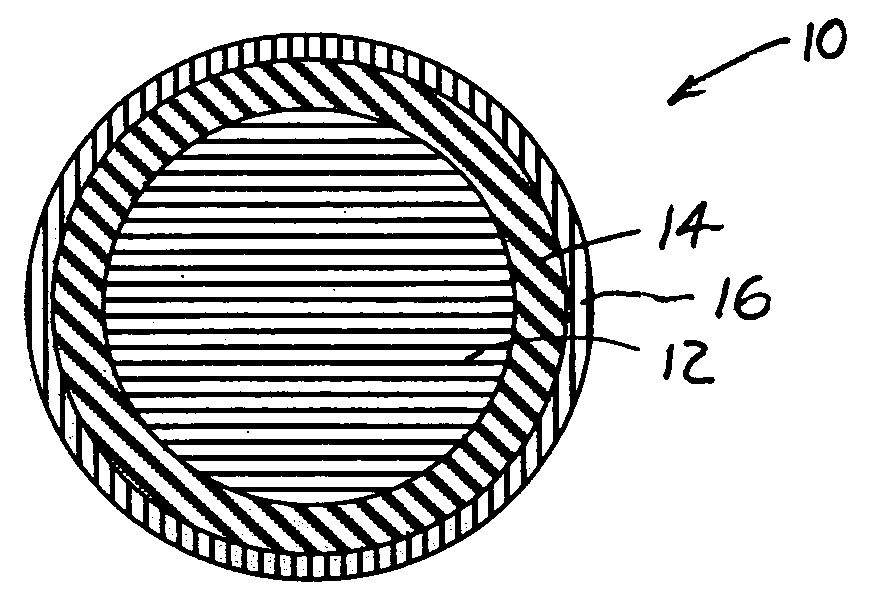

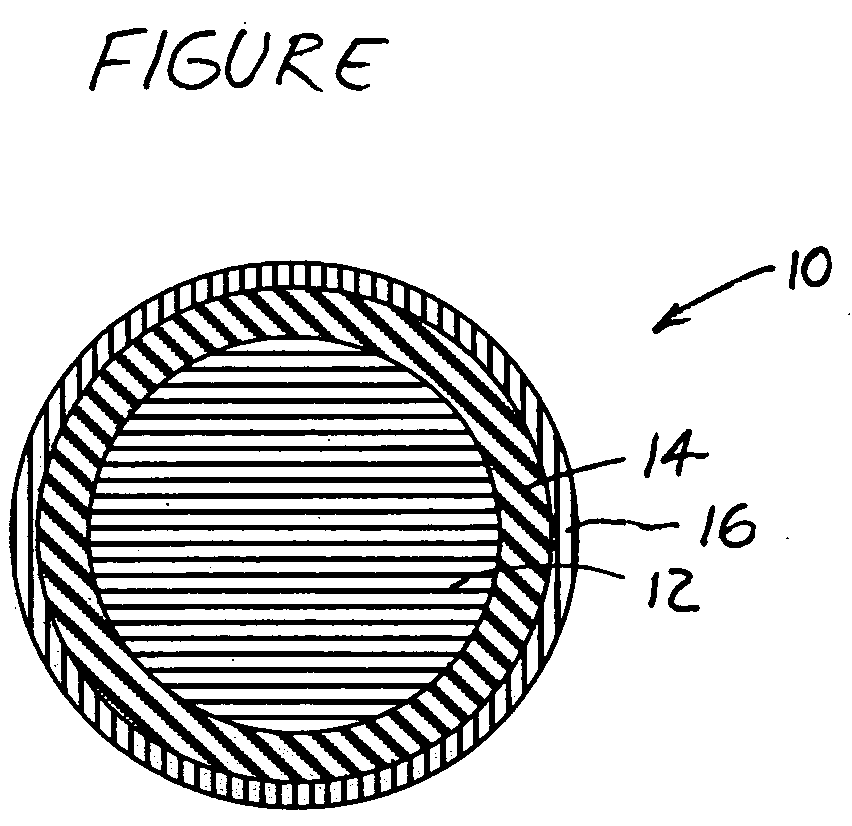

Multi-layer golf ball providing improved speed

a golf ball and multi-layer technology, applied in the field of golf balls, can solve the problems of increased distance, low spin rate, and longer manufacturing time, and achieve the effects of improving spin rate, increasing distance, and improving spin ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0132] Examples of the invention are given below by way of illustration and not by way of limitation.

Core Components and Preparation

[0133] A series of ball cores having diameters of 1.48 in., and suitable for use in golf balls within the scope of the present invention were prepared. Each core used the following materials:

[0134] BR40 is a cis-1,4-polybutadiene rubber made with a rare earth catalyst and is commercially available from Enichem (Italy).

[0135] ZnO is a rubber grade zinc oxide commercially available from Akrochem (Akron, Ohio).

[0136] ZDA is zinc diacrylate and is commercially available from Sartomer. Several grades are available, which may be used interchangeably or in combination.

[0137] Varox 231XL is 1,1-di(t-butylperoxy)-3,3,5-trimethyl-cyclohexane is a cross-linking initiator (40% active peroxide). This is commercially available from R. T. Vanderbilt (Norwalk, Conn.).

[0138] The cores each incorporated as the base rubber, cis-1,4-polybutadiene. Additionally, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com