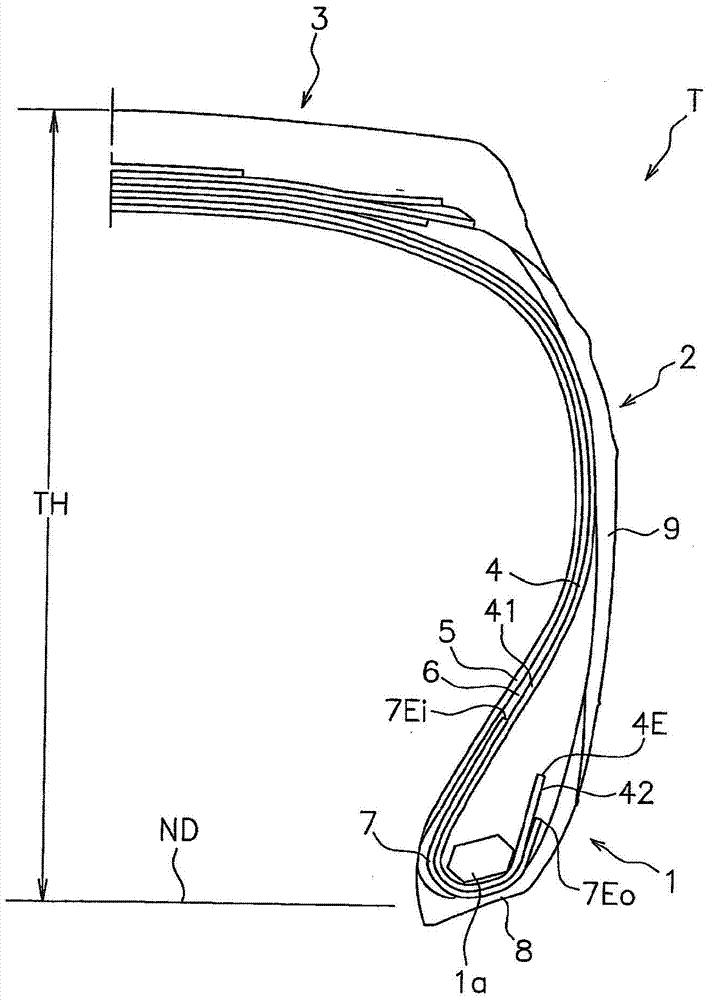

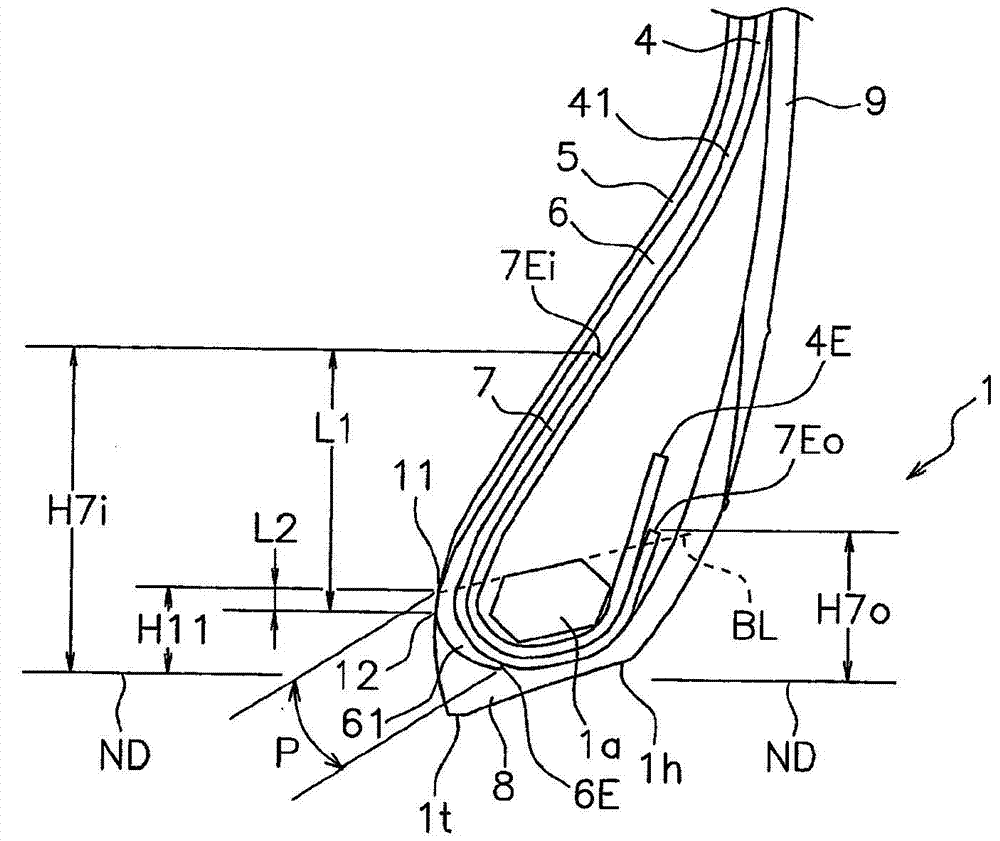

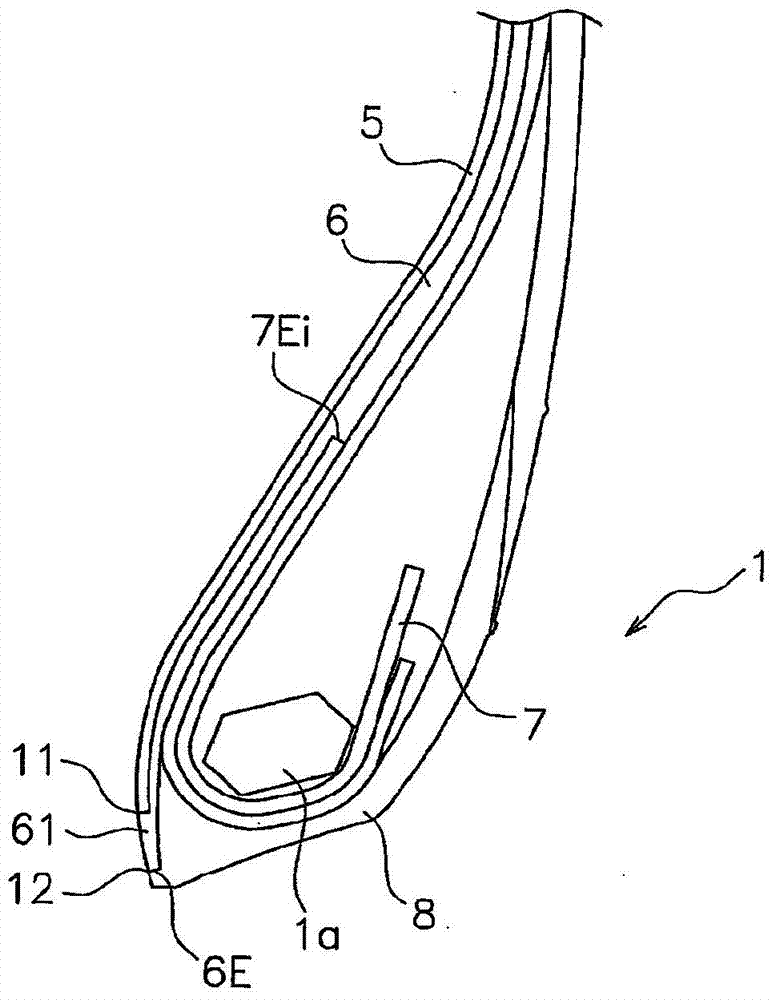

Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire edges, transportation and packaging, etc., can solve problems such as cracks, and achieve the effects of excellent affinity, inhibition of cracks, and small difference in hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0057] Hereinafter, an embodiment concretely showing the structure and effects of the present invention will be described. Each test was performed as shown below.

[0058] (1) Durability test used to check crack resistance

[0059] A drum test machine (drum test machine) was used to drive the tire with standard internal pressure and standard load for 100,000 km. After that, the tire was removed from the rim, and the presence or absence of the tire on the bead portion was confirmed Cracking occurred. Here, the standard internal pressure refers to the air pressure corresponding to the maximum load (maximum load capacity) of the wheel of the applicable model described in JATMA; the standard load refers to the maximum load (the maximum load capacity) of the wheel of the applicable size described in JATMA .

[0060] (2) Air penetration test

[0061] In a temperature-controlled room, the tires with standard internal pressure were left for three months, and the subsequent internal pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com