Sensor system and method for characterizing stacks of wet paint layers

A layer stack, sensor technology, used in instruments, scientific instruments, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Detailed Description of Aspects of the Invention

[0025] In the following, some further aspects of the invention are described. Unless expressly stated otherwise, these aspects are independent of each other and can be combined in any way. For example, any aspect or example described in this document may be combined with any other aspect or embodiment.

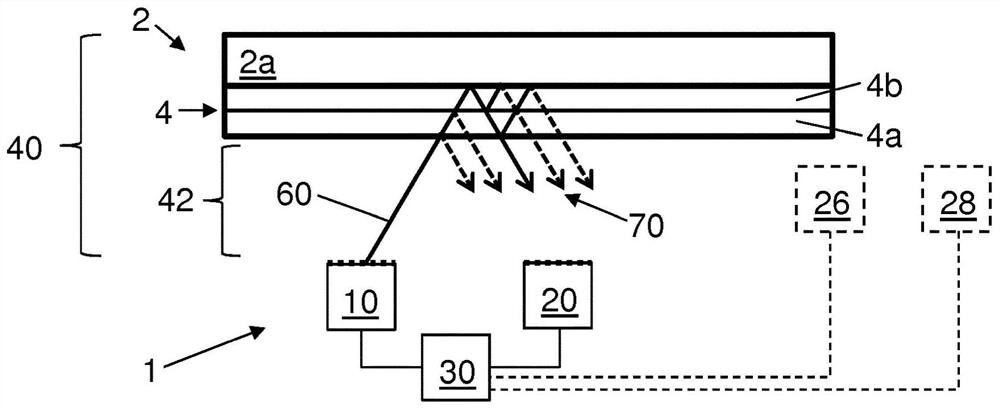

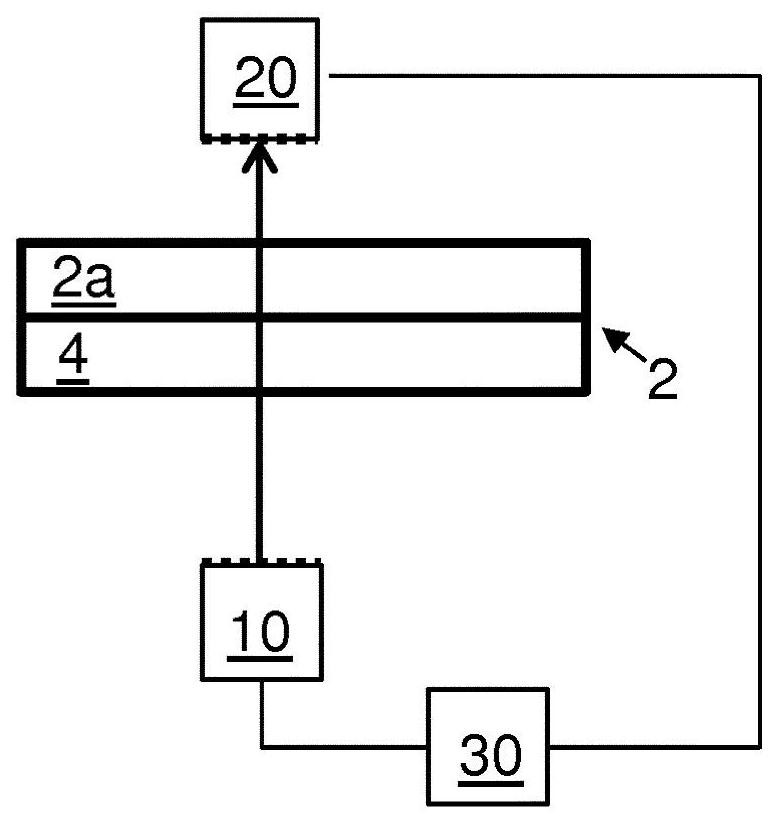

[0026] First, some general aspects are described. According to an aspect of the invention, there is provided a method for determining the current thickness of at least one wet paint layer in a stack of at least two wet paint layers (also referred to herein as a wet paint layer stack). Furthermore, the method allows determining a predicted dry paint layer thickness of at least one, several and / or all wet paint layers in such a stack of wet paint layers. In this context, a wet paint layer is defined as a layer that is not yet dry and still has liquid or uncured components. This is only the case for paints that were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com