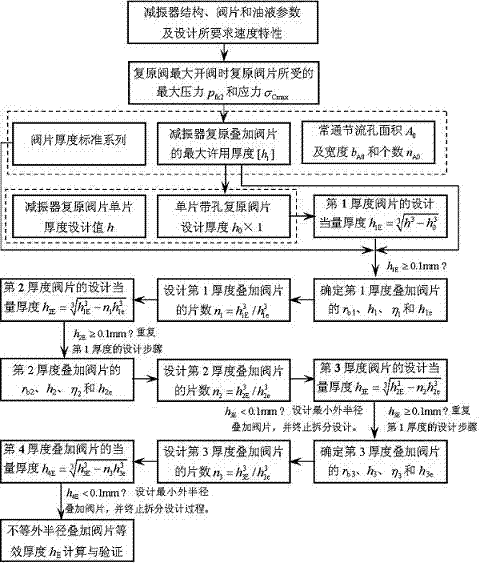

Split design method of non-isostructural superimposed valve plate of shock absorber recovery valve

A technology for restoring valve plates and design methods, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of difficult design to obtain accurate and reliable non-equivalent structure stacking valve plate thickness and number of plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

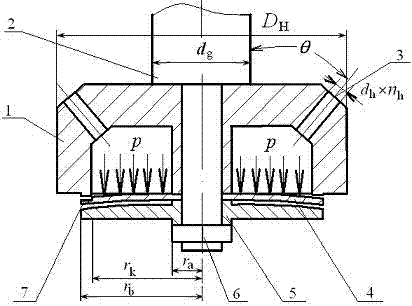

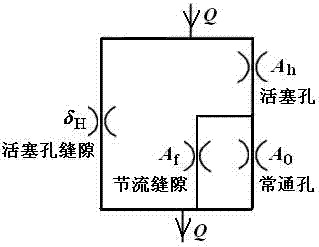

[0077] Example 1: The structure diagram of a shock absorber piston assembly and recovery valve is as follows figure 2 As shown, among them, the piston body 1, the piston rod 2, the piston hole 3, the recovery valve plate 4, the limit retaining ring 5, the fastening nut 6, and the normally open orifice 7. The speed characteristic curve required by the shock absorber design is as follows Figure 5 Shown, the return stroke maximum valve opening speed V k2 =1.0m / s, the required maximum valve opening damping force F dk2=1650N; Piston rod diameter d g =20mm, inner diameter of piston cylinder D h =28mm; Piston average clearance δ H =0.04mm, piston gap length, L H =9mm Eccentricity e=1.0; Oil density ρ=890kg / m 3 , kinematic viscosity ν=10.0×10 -6 m 2 / s, dynamic viscosity μ t =8.9×10 -3 Pa.s; the physical length of the piston hole L h =9.0mm, the angle is θ=52°, the diameter of the piston hole is d h =2.0mm, number n h =4; The radius r of the inner circle of the restorat...

Embodiment 2

[0131] Embodiment 2: The structural parameters and oil parameters of a certain shock absorber are the same as those in Embodiment 1, except that the maximum valve opening speed point V of the shock absorber is k2 =1.20m / s, the damping force of restoring valve opening is F dk2 =2000N, the speed characteristic curve required by the shock absorber design is as follows Figure 7 As shown, the design thickness of the single-piece restoration valve is h=0.30046mm, and the area A of the normally open orifice of the restoration valve is 0 =0.8mm 2 , usually the width of the through hole b A0 =2.0mm, the number is n A0 =4.

[0132] The calculation steps of Embodiment 1 are adopted, namely:

[0133] (1) Determine the maximum pressure p on the recovery valve plate when the shock absorber is at its maximum valve opening fk2 :

[0134] Step A: Determine the piston gap throttling pressure p at the maximum valve opening of the shock absorber Hk2 and flow Q Hk2 :

[0135] According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com