Dispersion liquid of colored resin fine particles for aqueous inks, and aqueous ink composition for writing utensils using same

A fine-grained, water-based ink technology, applied in home appliances, inks, applications, etc., can solve problems such as non-existence, and achieve the effect of improving the dryness of tracing lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

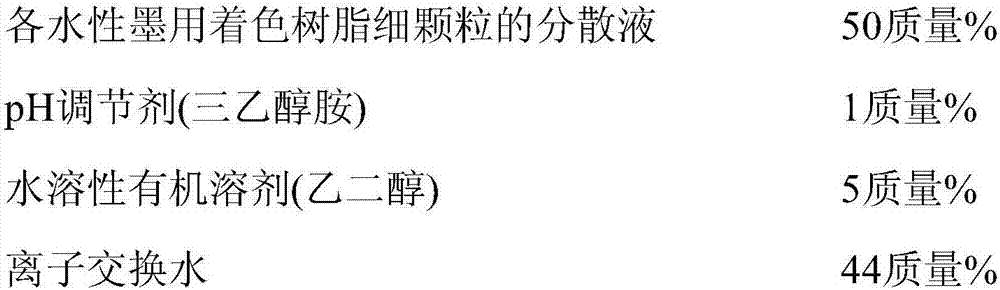

Examples

Embodiment 1 to 17 and comparative example 1 to 4

[0075] Dispersions of colored resin fine particles for each aqueous ink were prepared in Examples 1 to 17 and Comparative Examples 1 to 4 by the following production methods.

Embodiment 1

[0077] A 2-liter flask equipped with a stirrer, a reflux condenser, a thermometer, a nitrogen inlet tube, and a 1000-ml separatory funnel for adding monomers was placed in a hot water bath, and 500 g of distilled water, 50 g of a polymerizable surfactant (ADECA REASOAPSE-10N, manufactured by ADECA CORPORATION) and 3 g of ammonium persulfate, and heated to an internal temperature of 50° C. while introducing nitrogen gas.

[0078] On the other hand, 40 g of a water-soluble basic dye (AIZEN CTVTHILON RED BLH200%, manufactured by Hodogaya Chemical Co., Ltd.) was mixed with 300 g of 2-methacryloxyethyl phthalate (AcrylEster PA, Solubility in water: 0.08% by mass, manufactured by Mitsubishi Rayon Co., Ltd.) 500 g of mixed monomers as component (A) and 200 g of n-butyl methacrylate as component (B) were mixed to prepare a solution.

[0079] The above-prepared solution was added from a separatory funnel into a flask maintained at a temperature of about 50° C. under stirring within 3 h...

Embodiment 2

[0081] A dispersion of colored resin fine particles for aqueous ink was obtained in the same manner as in Example 1 above except that in Example 1, 150 g of n-butyl acrylate was used as the component (B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com