Isolated surrounding-type urban rail transit-used power composite cable

A technology of urban rail transit and composite cables, which is applied in the direction of power cables, power cables including electrical communication lines, and power cables including electric control, etc., which can solve problems such as increased weight, integration of optical cables and cables, and increased installation space , to achieve the effect of light weight, reasonable structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

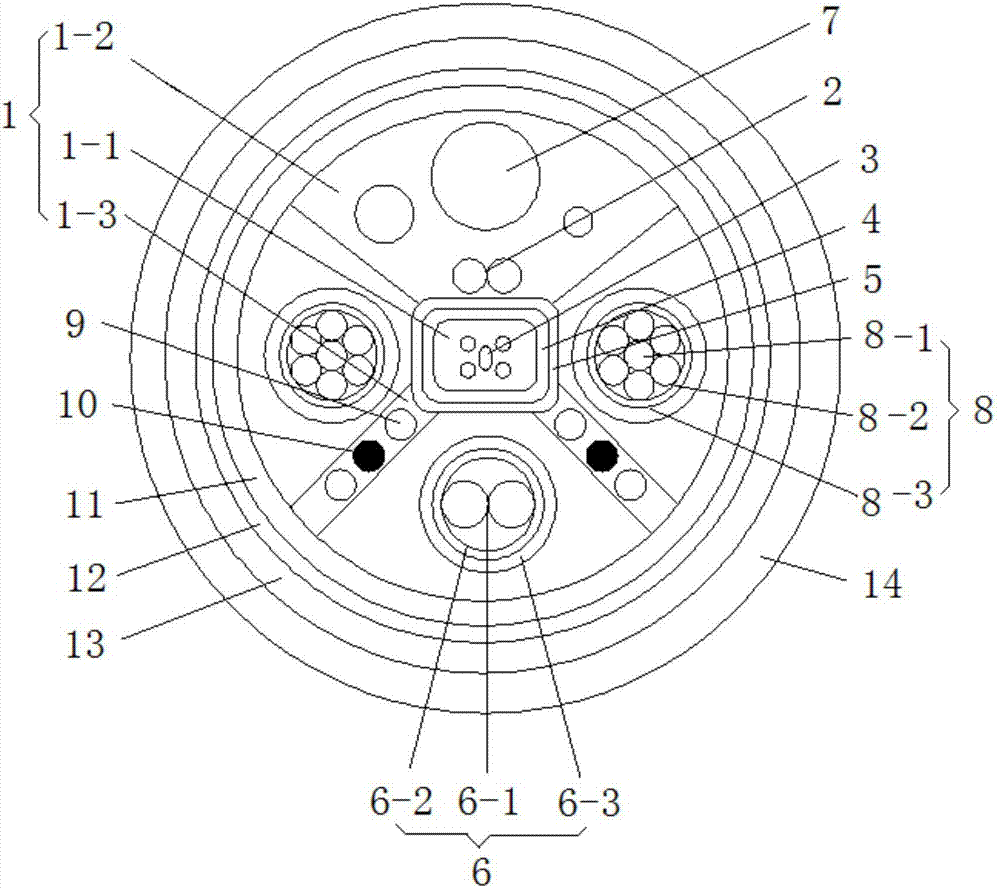

[0015] See attached picture:

[0016] The power composite cable for isolation and surrounding urban rail transit includes an ethylene-propylene rubber carrier layer 1, and the ethylene-propylene rubber carrier layer 1 is composed of a central core 1-1 with a square cross-section and four fan-shaped cores 1-2 around it , between one of the fan-shaped cores and the other two adjacent fan-shaped cores is provided with a strip-shaped isolation rib 1-3;

[0017] The middle core 1-1 is provided with a plurality of optical fiber cores 3, and the middle core 1-1 is successively covered with an aluminum foil wrapping shielding layer 4 and a silicon rubber protective layer 5; the fan-shaped core between the two isolation ribs 1-3 There is a data cable core 6 inside, and a plurality of power line cores 7 of different specifications are arranged in the sector core opposite to the data line core 6; control line cores 8 are provided in the other two opposite sector cores; isolation ribs 1-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com