A new type of durable hot-extruded polyethylene steel wire rope straddle sling

A steel wire rope and steel wire rope technology, applied in the field of bridge engineering, can solve the problems of aggravating the corrosion of the wire rope sling, affecting the service life of the sling, and being unable to effectively resist the dynamic and static load and deformation of the wire rope sling, so as to save painting and maintenance cost, good anti-ultraviolet aging performance, and good environmental stress cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

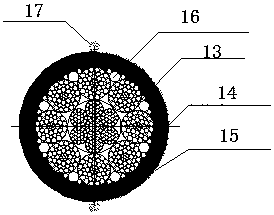

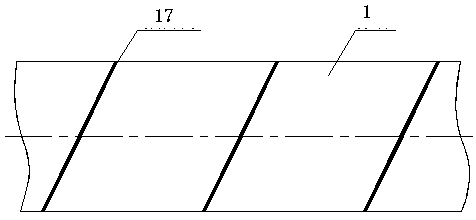

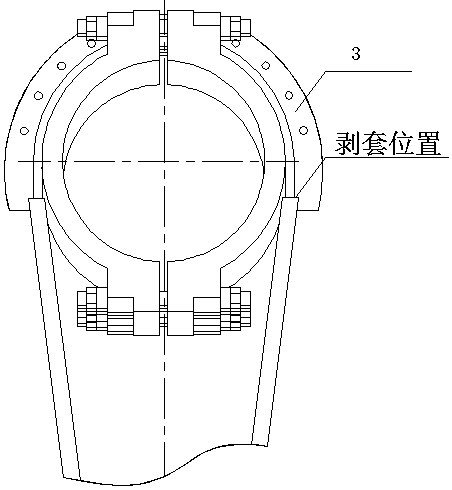

[0042] The novel durable heat-extruded polyethylene steel wire rope straddle type sling structure in this embodiment includes a wire rope sling 1, a cable clamp 2, a protective cover 3, a wire rope sling clamp, a steel wire rope shock absorber, and a wire rope anchor head, the multi-strand steel wire rope sling rides on the cable clamp 2, the steel wire rope sling clamp is arranged on the steel wire rope sling below the cable clamp, and the steel wire rope sling shock mount is arranged on the steel wire rope sling below the steel wire rope clamp; The outer periphery of clip 2 is formed with an embedded cable groove, and the wire rope sling rides in the embedded cable groove of the cable clip, and the steel wire rope sling is stripped at the position in contact with the cable clip to form a bare steel wire section. Filled with butyl rubber mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com