A kind of preparation technology of low-sodium corundum

A preparation process, corundum technology, applied in the field of low-sodium corundum preparation process, can solve the problems of heavy environmental pollution, low efficiency, time-consuming and labor-intensive, etc., to achieve the effects of eliminating pollution, improving production efficiency, and increasing the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

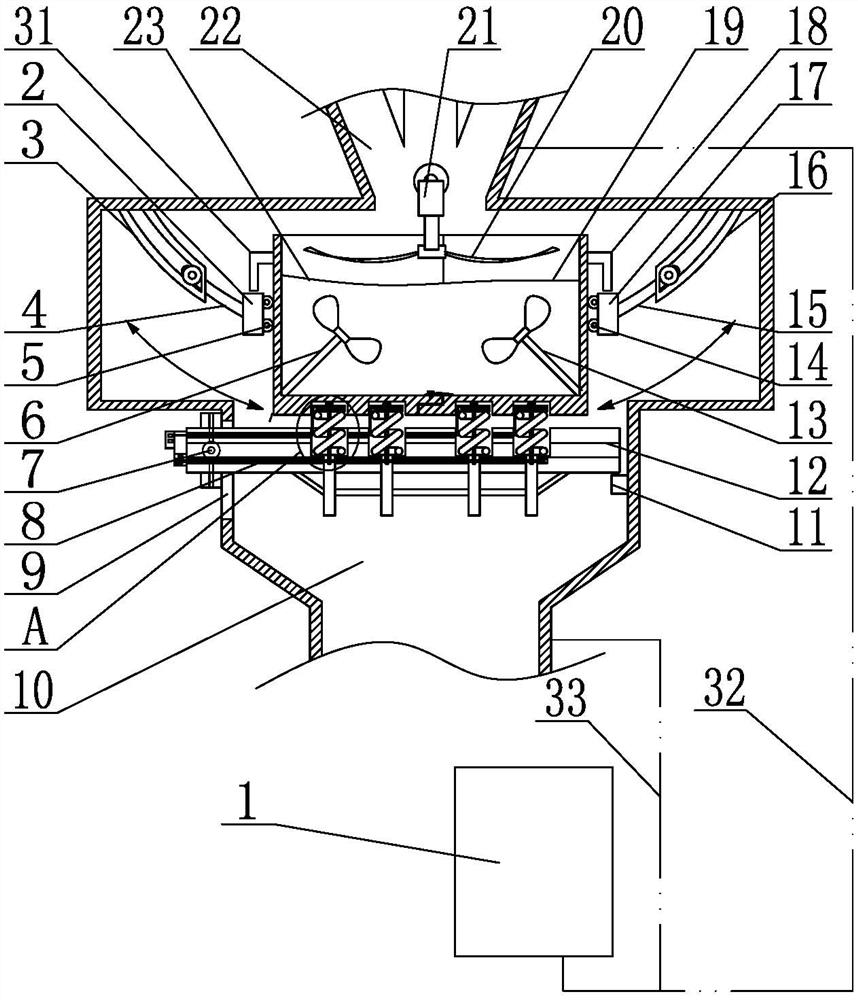

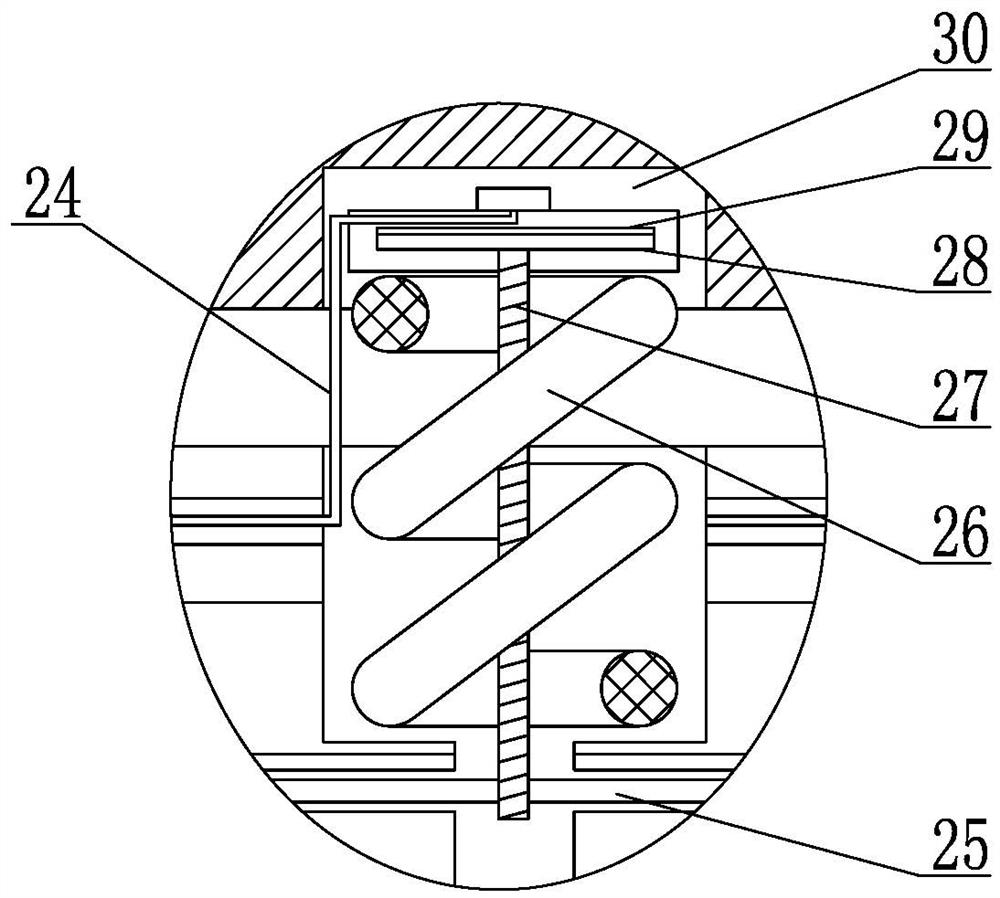

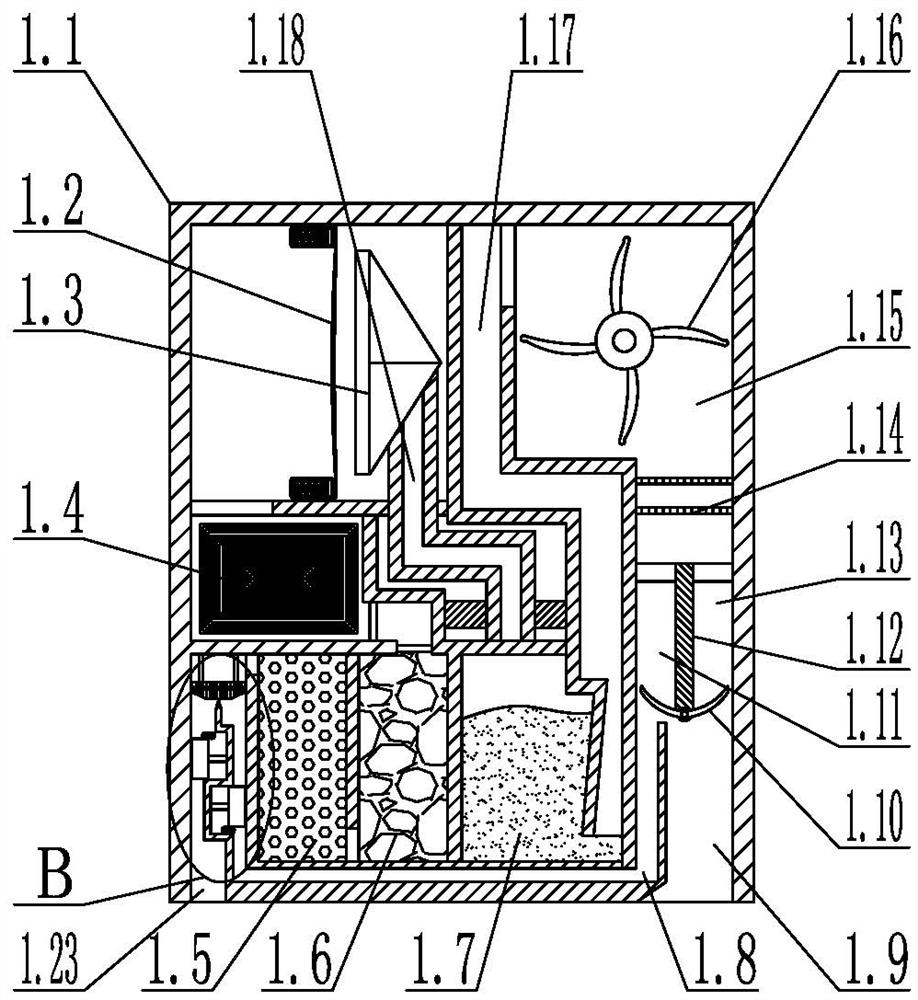

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] A preparation process of low-sodium corundum, the required raw materials include the following components in terms of mass:

[0054] Industrial alumina 100-105 parts,

[0055] 5-10 parts of acetic acid or boric acid,

[0056] 10-15 parts of ammonium chloride,

[0057] Aluminum oxide 2-10 parts.

[0058] Concrete embodiment sees the following table:

[0059] Raw material components Embodiment one Embodiment two Embodiment Three Industrial alumina 100 copies 102 copies 105 copies Acetic or boric acid 5 copies 8.5 servings 10 copies ammonium chloride 10 copies 12 copies 15 copies Aluminum oxide 2 copies 6 servings 10 copies

[0060] The chemical composition of described industrial aluminum oxide is as follows:

[0061] Silicon oxide 0.01-0.02%,

[0062] Iron oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com