Antibacterial and antistatic ceramic glaze with high wear resistance and preparation method for ceramic tile

An anti-static and wear-resistant technology, applied in the field of architectural ceramics, can solve the problems of poor anti-slip and high-temperature resistance, expensive conductive materials, and reduced material purity, so as to achieve good anti-slip effect, uniform and stable flow distribution, and improve anti-slip The effect of fouling performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

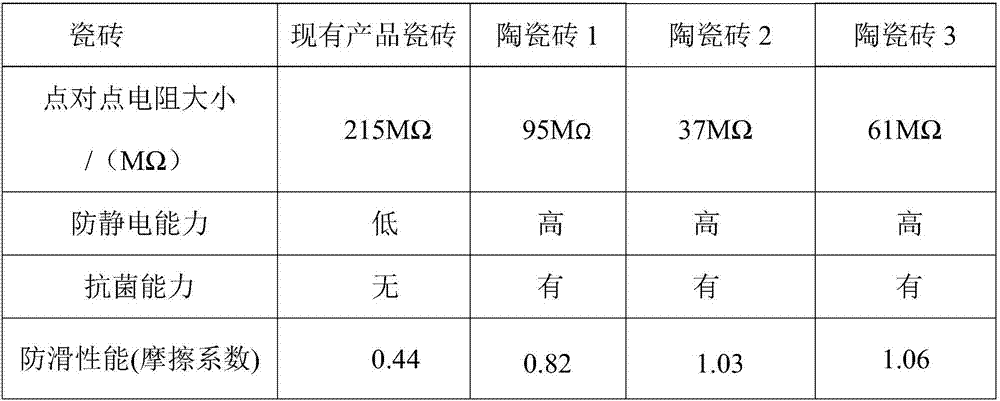

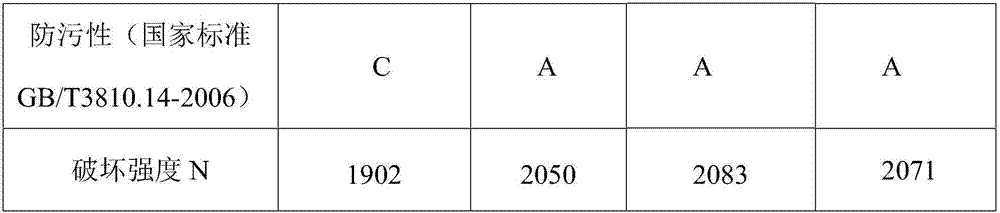

Embodiment 1

[0037] Embodiment 1-a kind of preparation method of ceramic brick with antibacterial and antistatic function, comprises the steps:

[0038] (1) Prepare antibacterial and antistatic glaze: first prepare antistatic glass frit, nanocomposite antibacterial particles, aluminum oxide whiskers and printing oil with a mass ratio of 1:0.8:0.5:2.5; The fineness of the block is 60 mesh;

[0039] Wherein, the antistatic glass frit includes 24% conductive powder mixed with conductive tin oxide and conductive titanium oxide, and the mixture composed of 76% glass powder is obtained by melting, cooling and crushing into granules; Said nanocomposite antibacterial particles are made by ball milling and drying the aqueous solution containing strontium ions, rare earth ions and layered clay; the concentration of strontium ions in said aqueous solution is 2.5mmol / L, and the concentration of rare earth ions is 5.5mmol / L. The concentration of the clay is 18g / L; The printing oil adds 1% carboxymethy...

Embodiment 2

[0044] Embodiment 2-a kind of preparation method of ceramic brick with antibacterial and antistatic function, comprises the steps:

[0045] (1) Prepare antibacterial and antistatic glaze: first prepare antistatic glass frit, nanocomposite antibacterial particles, zinc oxide whiskers and printing oil with a mass ratio of 1.5:0.5:2:2; The fineness of the block is 125 mesh;

[0046] Wherein, the antistatic glass frit includes 50% conductive powder mixed with conductive zinc oxide, conductive iron oxide and conductive barium titanate, and the mixture composed of 50% glass powder is melted, cooled and broken into The nanocomposite antibacterial particles are obtained by ball milling and drying the aqueous solution containing strontium ions, rare earth ions and layered clay; the concentration of strontium ions in the aqueous solution is 6mmol / L, and the concentration of rare earth ions is 16mmol / L L, the concentration of layered clay is 35g / L; Described printing oil adds 0.5% carbo...

Embodiment 3

[0051] Embodiment 3-a kind of preparation method of ceramic brick with antibacterial and antistatic function, comprises the steps:

[0052] (1) Prepare antibacterial and antistatic glaze: first prepare antistatic glass frit, nanocomposite antibacterial particles, zirconia whiskers and printing oil with a mass ratio of 1.3:0.6:1:2.3; the antistatic glass frit The fineness of the block is 100 mesh;

[0053] Wherein, the antistatic glass frit includes conductive powder mixed with 45% conductive barium titanate and conductive lead titanate, and the mixture composed of 55% glass powder is obtained by melting, cooling and crushing into granules The nanocomposite antibacterial particles are prepared by ball milling and drying the aqueous solution containing strontium ions, rare earth ions and layered clay; the concentration of strontium ions in the aqueous solution is 4mmol / L, and the concentration of rare earth ions is 10.5mmol / L, The concentration of layered clay is 25g / L; The pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com