Label induction shearing device

A technology of shearing device and cutting device, which is applied in metal processing and other directions, can solve the problems affecting the size of labels, etc., and achieve the effects of improving work efficiency, low energy consumption and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

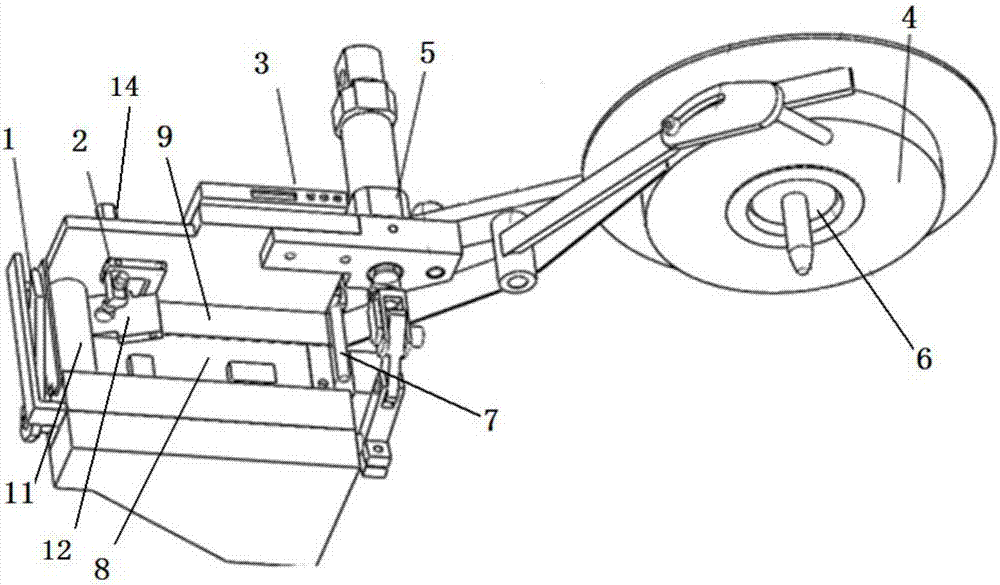

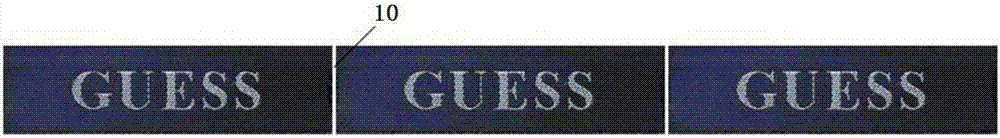

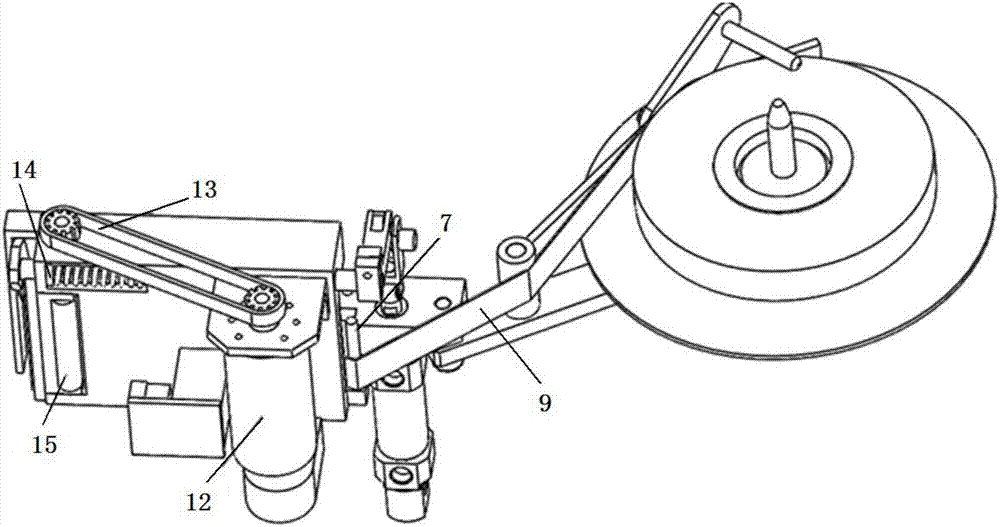

[0026] Such as figure 1 As shown, a label induction shearing device includes a machine table with a feeding plate 8 on the machine table, and a label roll storage device 6 is arranged on one side of the machine table, and a label roll 4 is stored on the label roll storage device 6, and the label roll 4 is formed by winding the label tape 9, and the structure of the label tape 9 is as follows figure 2 As shown, the label strip 9 has a plurality of single labels arranged at a certain distance, and the gaps between adjacent single labels are label segmentation marks 10 . One end of the feeding plate 8 is provided with a pressure rod 7, and the other end is provided with an upper roller 11 and a lower roller 15 placed opposite to each other. The label tape 9 coming out of the label roll 4 is pasted on the upper surface of the feeding plate 8 after being turned by the pressure rod 7. Move forward and enter between the upper roller 11 and the lower roller 15 , the outer sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com