Method of preparing high-orientation two-dimensional metal-organic frameworks nanosheet-type film through induced growth of zinc oxide in limited range of graphene oxide

A metal-organic framework and nanosheet technology, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve the problems of complex preparation of 2DMOFs nanosheet membranes, difficulties and difficulties in the preparation of nanosheet membranes, etc., and achieve excellent gas Separation effect, good magnification and application prospects, high orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The carrier is an alumina ceramic tube carrier with an average pore diameter of about 0.1-2 μm. Before synthesis, use deionized water and ethanol to ultrasonically wash several times to remove surface particles and stains, and dry them for later use.

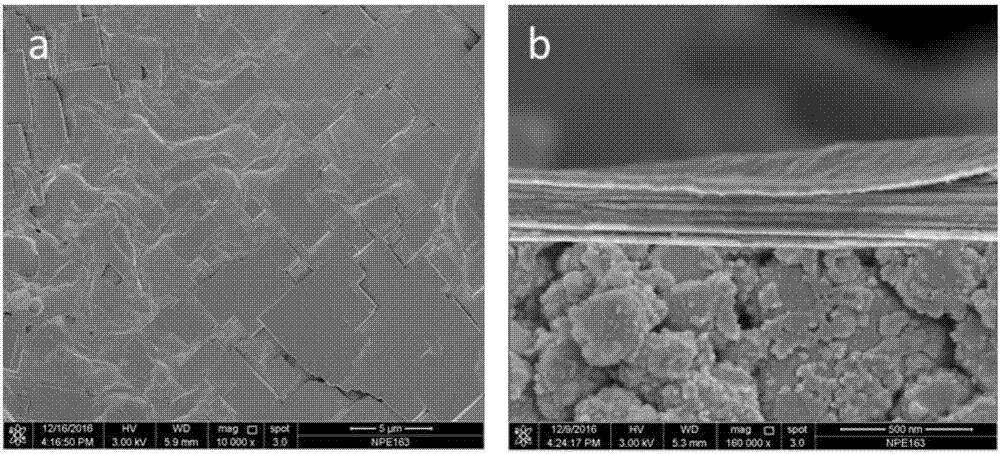

[0031](2) 8.2624g of zinc acetate was dissolved in 50mL of ethylene glycol methyl ether solvent and 4.6mL of ethanolamine was used as a stabilizer to form a ZnO sol solution with a mass fraction of zinc of 30%. Then, a zinc sol layer was formed on the alumina ceramic carrier tube in step (1) by pulling coating, and dried at 100° C. for 1 hour, and repeated 3 times. After drying, it was baked in a muffle furnace at a programmed temperature of 500° C. for 4 hours to obtain a porous carrier with a ZnO coating.

[0032] (3) Dissolve 0.2g of graphite oxide powder in 126mL of anhydrous methanol, and sonicate for 2h. Put the graphite oxide methanol solution into a centrifuge and centrifuge at 7000rpm for 30min, remove the ...

Embodiment 2

[0035] (1) and (2) are the same as embodiment 1 step (1) and step (2).

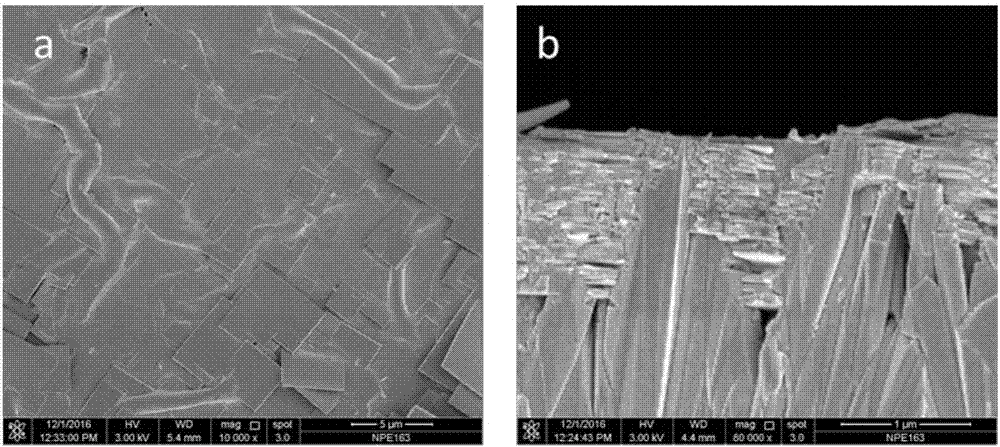

[0036] (3) Suspend the alumina ceramic tube with ZnO particles in an 80mL aqueous synthesis kettle containing 2.3798g zinc nitrate hexahydrate and 1.1216g hexamethylenetetramine, and react at 100°C for 5h to obtain ZnO nanoarray rods Ceramic tube.

[0037] (4) With embodiment 1 step (3).

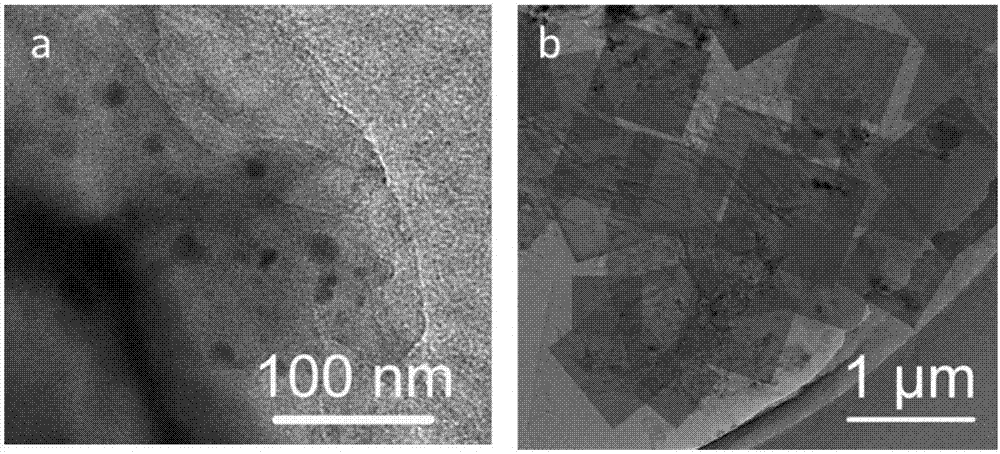

[0038] (5) The ceramic carrier with ZnO nano-array rods and graphene oxide film is placed in a 1.15g molar ratio containing bIm: NH 3 ·H 2 O: PhMe: CH 3 In the synthesis solution of OH=1:1:40:60, the solvothermal growth reaction was carried out at 120°C for 12 hours, the film tube was taken out and the surface of the film layer was slowly rinsed with methanol, and then dried naturally to obtain a nanosheet film with horizontal orientation growth.

Embodiment 3

[0040] (1) With embodiment 1 step (1).

[0041] (2) 4.6322g of zinc acetate was dissolved in 50mL of ethylene glycol methyl ether solvent and 2.3mL of ethanolamine was used as a stabilizer to prepare a ZnO sol solution with a mass fraction of zinc of 15%. Then, the zinc sol layer was formed on the alumina ceramic carrier tube in step (1) by pulling once, and dried at 100° C. for 1 hour. After drying, it was baked in a muffle furnace at a programmed temperature of 500° C. for 4 hours to obtain a porous carrier with a ZnO coating.

[0042] (3) Dissolve 0.1 g of graphite oxide powder in 60 mL of anhydrous methanol, stir overnight, and sonicate for 2 h. Put the methanol solution of graphite oxide in a centrifuge and centrifuge at 7000rpm for 30min, remove the bottom dregs and take the supernatant, then add 60ml of anhydrous methanol, ultrasonicate for 2h, put it in the centrifuge and centrifuge at 10000rpm for 30min, remove the bottom dregs and take the supernatant. Then, pull f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com