Fabrication method of gold-plated finger board

A manufacturing method and technology of finger boards, which are applied in chemical/electrolytic methods to remove conductive materials, manufacture printed circuits, and form electrical connections of printed components. The effect of spending on obsolescence problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

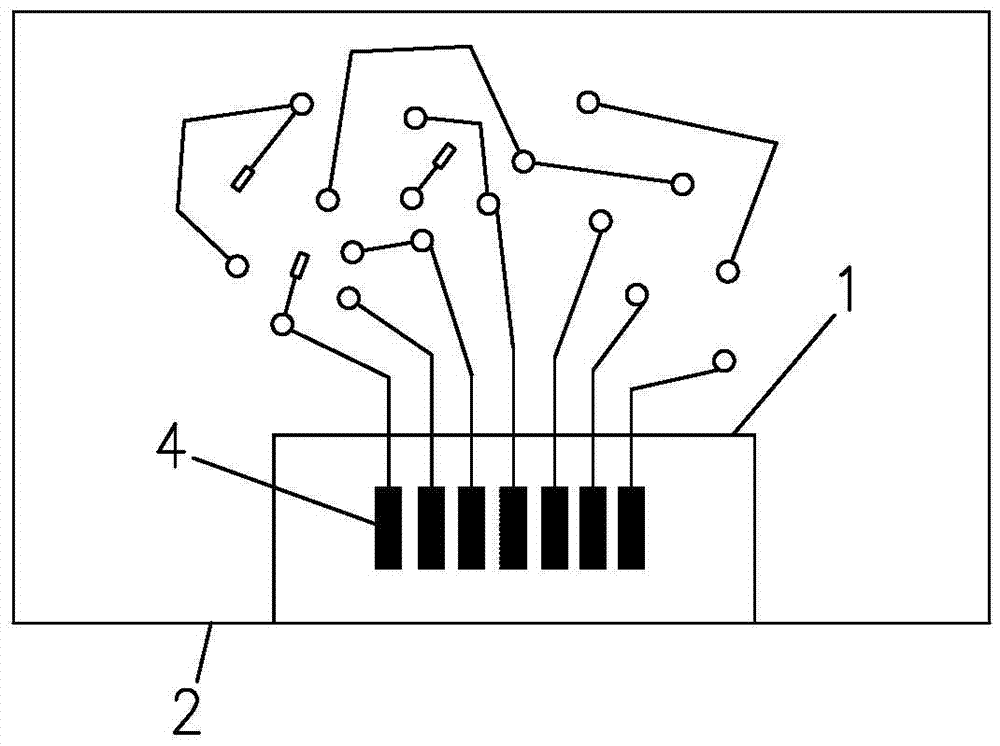

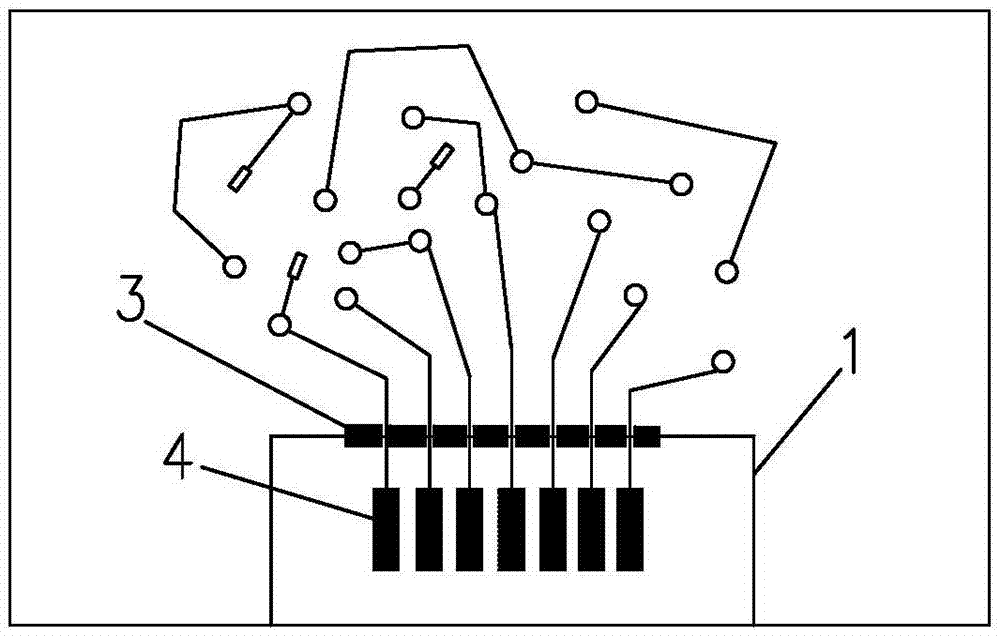

[0030] Such as figure 1 It is a traditional gold-plated finger board manufacturing method. This method will leave a small section of the secondary lead 1 on the top of the gold finger 4. When the gold finger 4 is beveled, there will be exposed copper on the top of the finger 4 and residual bumps on the secondary lead 1 resulting in a gold surface The quality of the scratching problem is not easy to control.

[0031] The present invention is a method for manufacturing a new type of gold-plated finger plate, which includes the following steps:

[0032] A1. Cutting: Cut the board to a size that meets the design requirements;

[0033] A2, paste the inner layer dry film: paste the photosensitive dry film on the board with the cut sheet as the inner layer;

[0034] A3. Inner layer graphics transfer: u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com