Compound semiconductor thermoelectric material and method for manufacturing same

A technology of thermoelectric materials and semiconductors, which is applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, components of thermoelectric devices, etc. Large-scale production and other issues, to achieve the effect of reducing thermal conductivity and high-efficiency thermoelectric cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

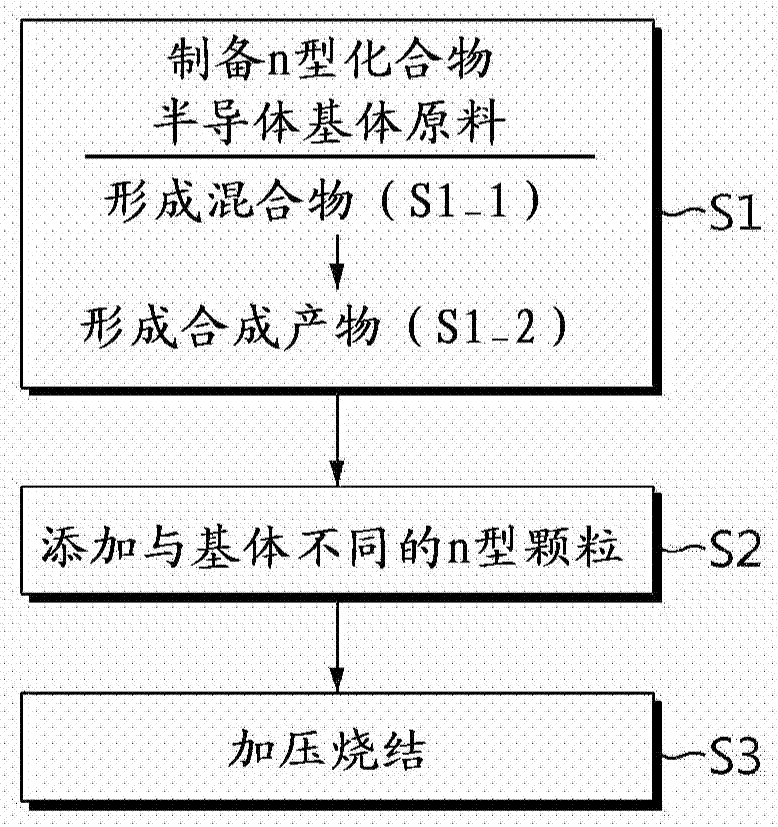

[0096] The reactants Bi, Te and Se pellets were prepared and ground, and mixed using a hand mill to produce Bi 2 Te 2.68 Se 0.32 The composition of the mixture (BTS material). Those containing added metal powders, especially Zn and / or Cu, were prepared to tune the properties of the Bi-Te-Se system. Furthermore, the mixture was put into a quartz tube and sealed under vacuum to produce an ampoule, and the ampoule was placed in a tube furnace, followed by heat treatment at a temperature of 400° C. for 12 hours.

[0097] The powder synthesized by the heat treatment was pulverized / classified using a sieve with a mesh size of 75 μm.

[0098] To prepare InSb and InSb:Se materials to be used as n-type particles, In, Sb and Se pellets were each loaded into a quartz tube and sealed under vacuum. Se is added in an amount of 0.1 mol % relative to InSb. Melting was carried out in a quartz tube in a furnace at 600° C. for 10 minutes, followed by air cooling. The ingot produced by melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com