Gear and rolling cone compounded infinitely variable transmission

A technology of continuously variable transmission and rolling cone, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problems of low power transmission efficiency, complex structure, and inability to work at high speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

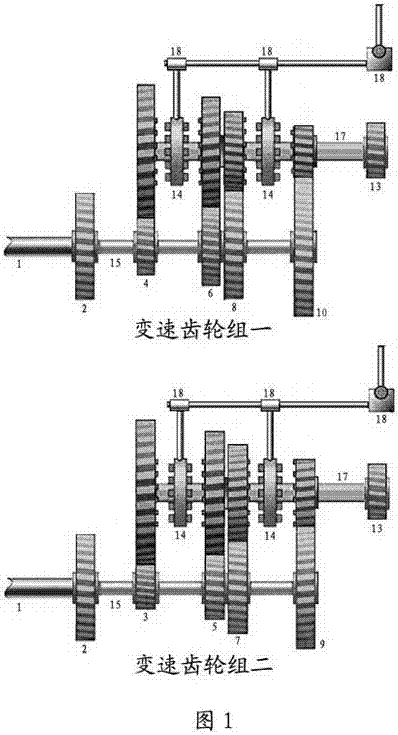

[0016] figure 1 Among them, the gear and rolling cone compound continuously variable transmission is divided into two rows of gear sets, which are the first gear set and the second gear set. The first gear set is responsible for the gear transmission of 2nd, 4th, 6th and 8th gear. Group 2 is responsible for gear transmission of 1st, 3rd, 5th and 7th gears. figure 1 The sleeve in the gear is installed on a freely slidable spline shaft. Under the action of external force, the sleeve is pushed into the corresponding gear by the shift fork, and the two gears are meshed to output power.

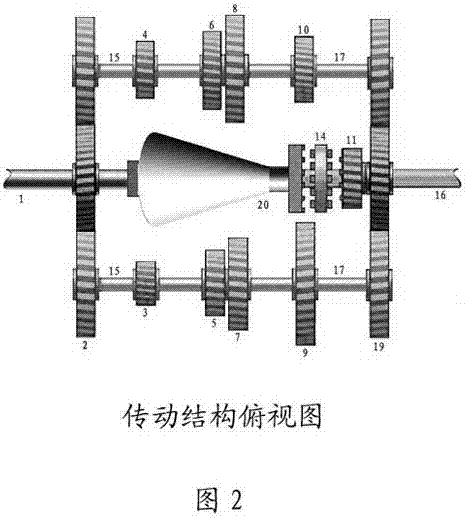

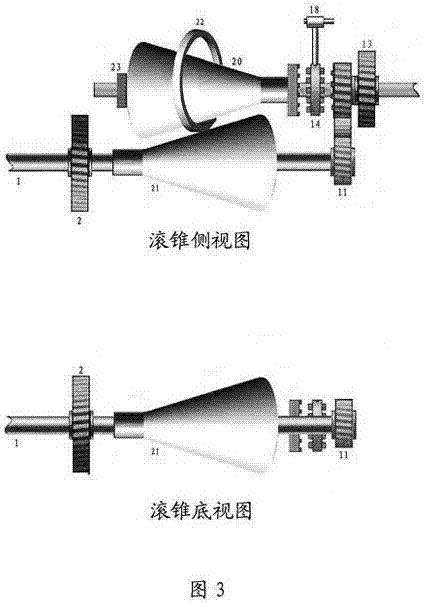

[0017] figure 2 It is the top view of the compound continuously variable transmission of gears and rollers. The two rows of speed change gear sets are respectively located on both sides of the rollers. There is a certain pressure between the lower roller cones. When the lower roller cone rotates, it drives the intermediate transmission part and the upper roller cone to rotate together. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com