Fire hose testing machine

A technology of fire hose and testing machine, which is applied in the direction of testing machinability and applying stable tension/pressure to test the strength of materials, etc. It can solve problems such as poor reliability, hose wear test, and low work efficiency, and achieve reliable Connection and sealing, preventing out-of-control speed, and ensuring the effect of speed synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

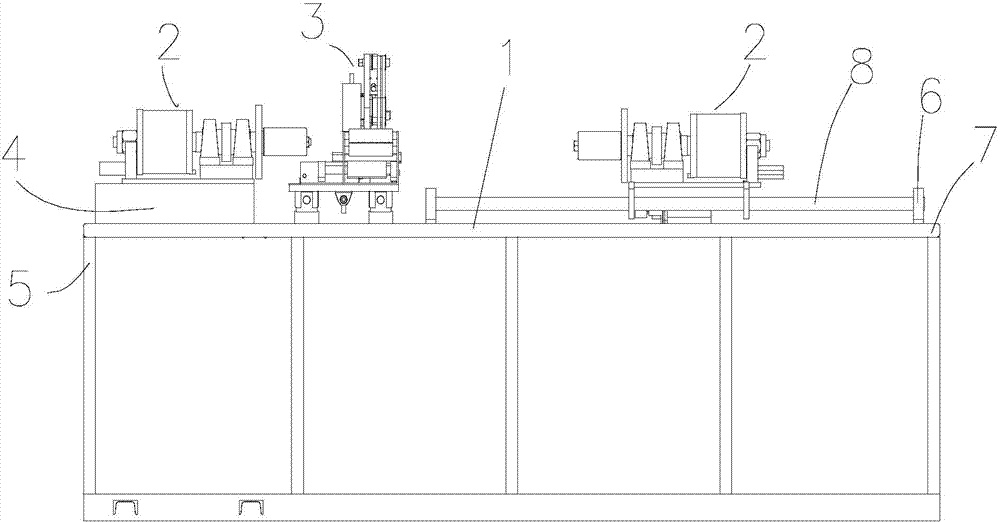

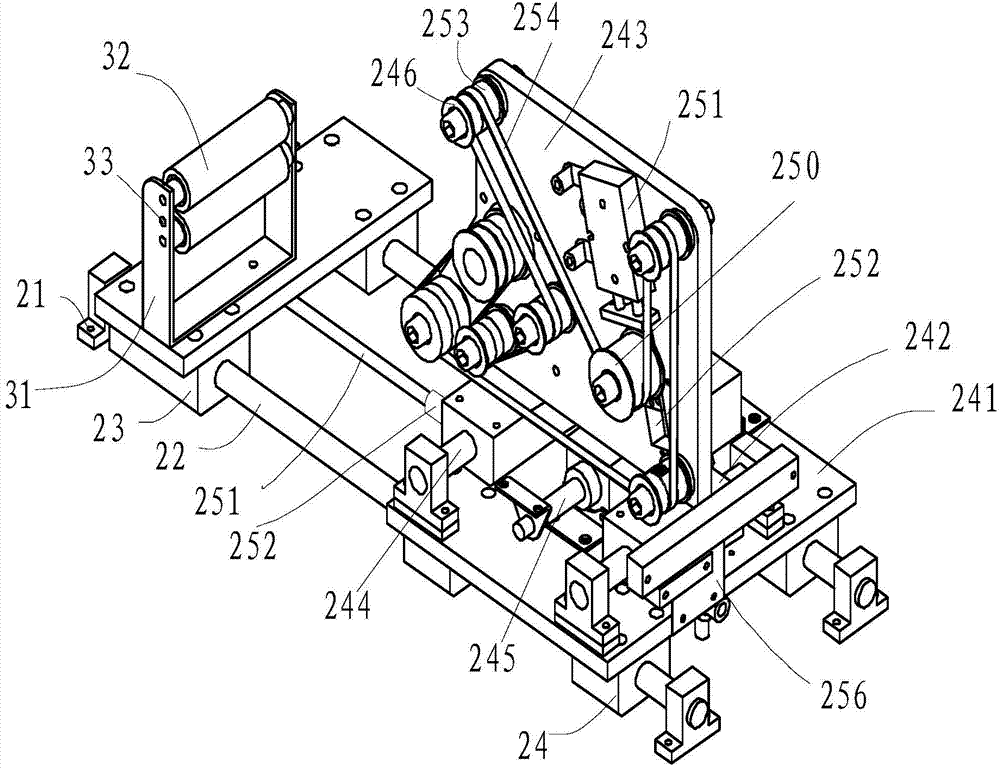

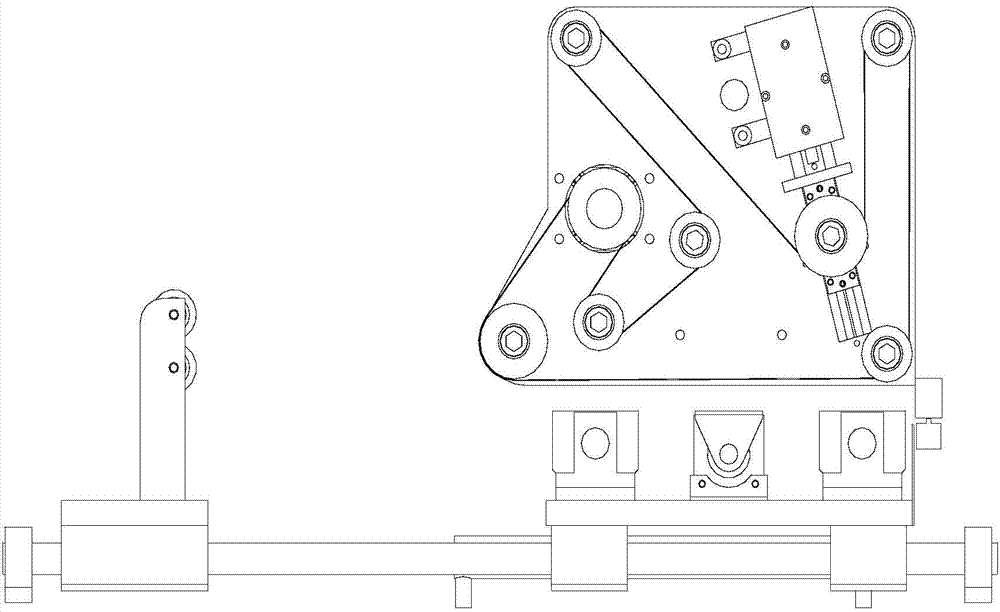

[0036] Such as Figure 1 to Figure 7As shown, a fire hose testing machine includes a body 1 and an electrical control system. The body 1 is provided with two hose rotary sealing devices 2 and a hose wear-resistant test device 3, and one of the hose rotary sealing devices 2 passes through The fixed bracket 4 is connected to one side of the head of the bed 5, and the other hose rotating sealing device 2 is connected to the foot of the bed 7 through the movable bracket 6, and the hose rotating sealing device 2 is connected to the movable bracket 6 through the guide shaft 8, and the two hose rotating seals The device 2 is respectively provided with a synchronous motor, and the two synchronous motors are connected to the same driver. The hose wear test device is set between the two hose rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com