Method for preparing artificial rutile from high titanium slag

A technology of artificial rutile and high-titanium slag, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high energy consumption, long roasting treatment time, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

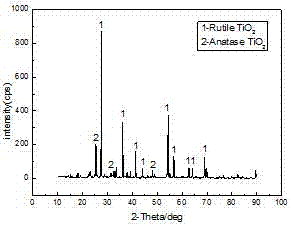

Image

Examples

preparation example Construction

[0034] The steps of the preparation method are as follows:

[0035] A. Crushing

[0036] First, the high-titanium slag is ground to -100 mesh to more than 80% by weight using a grinding device to obtain a high-titanium slag powder.

[0037] The high-titanium slag used in the present invention is a product obtained by separating slag and iron after ilmenite is smelted in an electric furnace. TiO by weight 2 The content of SiO is above 85%. 2 Below 4.0%.

[0038] Among them, TiO 2 The content is determined by the aluminum reduction method according to the GB / T1706-2006 standard. SiO 2 It is determined by perchloric acid dehydration gravimetric method according to YB / T190.1-2001 standard.

[0039] In the present invention, the existing grinding equipment and screening equipment are used for grinding and screening, for example, the grinding equipment sold by Nanchang General Laboratory Sample Preparation Factory under the trade name sealed sample preparation grinder (JG100-...

Embodiment 1

[0075] Embodiment 1: the preparation of artificial rutile

[0076] The implementation steps of this embodiment are as follows:

[0077] A. Crushing

[0078] The high titanium slag was chemically analyzed by the method described in this specification, and its TiO 2 The content is 85.5% by weight, SiO 2 At 3.94%. Grinding the high titanium slag to -100 mesh is more than 80% by weight using the grinding equipment sold by Nanchang General Laboratory Prototyping Machine Factory under the trade name sealed sample preparation grinder (JG100-3) to obtain a high titanium slag powder ,Then

[0079] B. Alkaline leaching to remove impurities

[0080] Mix the high-titanium slag powder obtained in step A with a sodium hydroxide solution with a concentration of 22% by weight according to a solid-to-liquid ratio of 1:5.5, and then use a constant temperature heating magnetic stirrer ( DF-101S) to carry out alkaline leaching and impurity removal treatment for 60 min, and then use the filt...

Embodiment 2

[0087] Embodiment 2: the preparation of artificial rutile

[0088] The implementation steps of this embodiment are as follows:

[0089] A. Crushing

[0090] The high titanium slag was chemically analyzed by the method described in this specification, and its TiO 2 The content is 86.3% by weight, SiO 2 At 3.87%. Grinding the high titanium slag to -100 mesh is more than 80% by weight using the grinding equipment sold by Nanchang General Laboratory Prototyping Machine Factory under the trade name sealed sample preparation grinder (JG100-3) to obtain a high titanium slag powder ,Then

[0091] B. Alkaline leaching to remove impurities

[0092] Mix the high-titanium slag powder obtained in step A with a sodium hydroxide solution with a concentration of 25% by weight according to a solid-to-liquid ratio of 1:6, and then use a constant temperature heating magnetic stirrer ( DF-101S) to carry out alkaline leaching and impurity removal treatment for 90 min, and then use the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com