Casting wax pattern raw material mixing device

A technology of mixing device and feeding device, which is applied to mixers, mixing methods, mixers with rotating stirring devices, etc., can solve the problems of inconvenient pouring, poor heat preservation effect, and affecting effects, and achieve convenient processing and cleaning. Prevent cooling and solidification, and ensure the effect of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

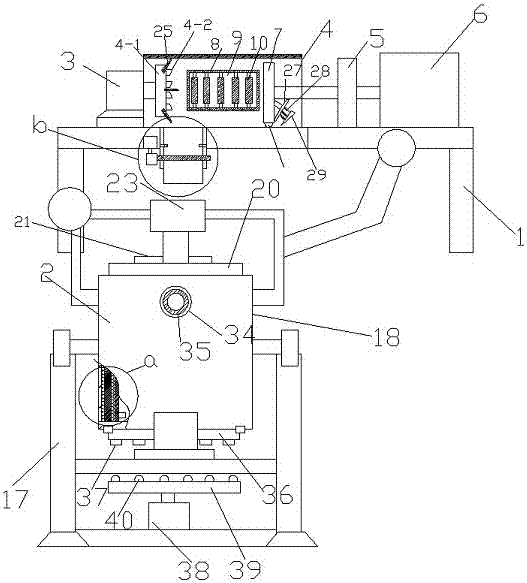

[0017] Such as figure 1 , 2 , 3, and 4 show: a kind of casting wax pattern raw material mixing device of the present embodiment, comprises upper support frame 1, and described upper support frame 1 is provided with wax shavings feeding device, wherein said wax shavings feeding A mixing device is provided directly below the discharge pipe 2 of the device, and the wax shavings feeding device includes a transmission motor 3, an operation box 4, a support plate 5 and a pushing cylinder 6, wherein the output shaft of the transmission motor 3 is connected to the The turntable 4-1 in the operation box 4 is connected and fixed, wherein the turntable 4-1 is provided with several blades 4-2 in turn, and the cylinder shaft of the pusher cylinder 6 passes through the support plate 5 and the operating The push plate 7 in the box 4 is connected and fixed; the discharge pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com