Prediction and optimization control method of machining chatter mark defect of oil casing screw splicer

A technology of optimization control and thread processing, which is applied in the field of petroleum equipment manufacturing, can solve problems such as lack of avoidance measures and difficulty in finding the cause of chatter marks, and achieve the effect of improving accuracy and controlling occurrence probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

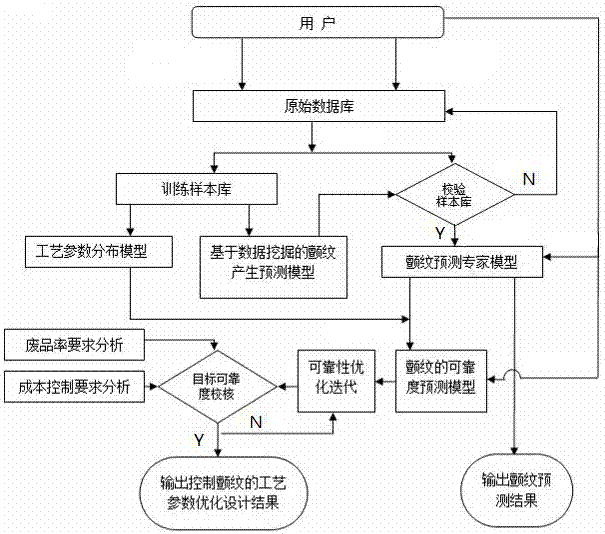

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] A method for predicting and optimizing control of chatter marks in machined threaded joints of oil and casing pipes, which mainly includes the following steps:

[0025] 1. The user establishes a database of actual chatter marks in thread processing of oil and casing pipes, and inputs and continuously accumulates, updates and stores multiple sets of thread processing process parameters of different steel grades, specifications and thread types and the corresponding actual chatter marks data on the thread surface in the database; The processing parameter data include: pipe overhang length, inner support and floating support roller related to pipe sample rigidity, cutter bar diameter and overhang length related t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap