Method for detecting off-flavor substances from fugitive emission of pickles plant by adopting SPME (solid-phase microextraction)-off-flavor analysis system

A technology of fugitive emission and analysis system, applied in the direction of analyzing materials, measuring devices, material separation, etc., can solve the problems of poor sensitivity and selectivity, inability to accurately detect the fugitive emission of odorous substances in pickle factories, and great influence of human factors, etc. Effects of high sensitivity, reduced background matrix interference, improved selectivity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

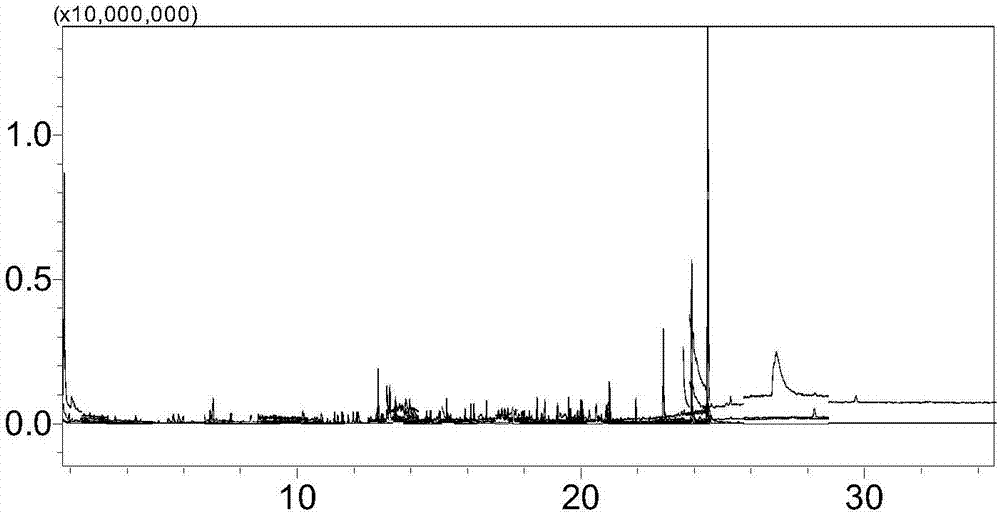

[0033] A method of solid-phase microextraction-odor analysis system of this embodiment detects unorganized emission of odorous substances from pickle factories, the steps are as follows:

[0034] Step 1. Sample collection:

[0035] (a) Aging of solid-phase microextraction fibers: 65 μm PDMS / DVB solid-phase microextraction fibers are aged at the inlet of gas chromatography before use. The aging temperature is 250 ° C, and the volume flow rate of carrier gas is 1.5 ml / min. No spurious peaks appeared.

[0036] (b) Collection of unorganized emission of odorous substances from pickle factories: According to "Technical Specifications for Layout of Ambient Air Quality Monitoring Points (Trial)" (HJ 664-2013) and "Technical Guidelines for Monitoring Unorganized Emissions of Air Pollutants" (HJ / T 55-2000), taking into account meteorological conditions, industrial layout, population distribution, roads and other factors, the sampling point was determined around a pickle factory in Jiang...

Embodiment 2

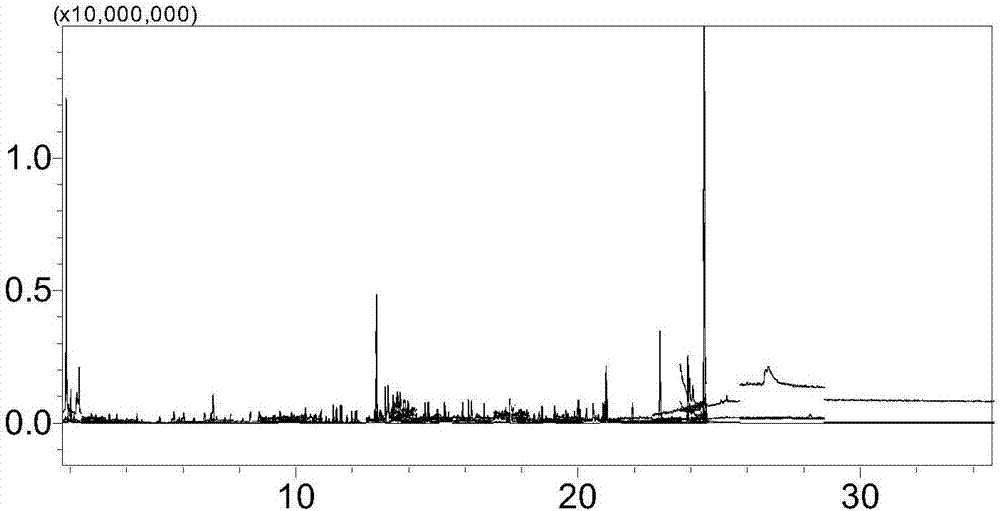

[0050] The 50 / 30 μm PDMS-DVB-CAR solid-phase microextraction fiber was used to collect fugitive odor substances emitted from pickle plants. The 50 / 30μm PDMS-DVB-CAR was aged in the inlet of the gas chromatograph before use. The aging temperature was 270°C, the volume flow rate of the carrier gas was 1.5ml / min, and the aging time was 0.5h. After collecting at the sampling point for 30 minutes, and transporting it back to the laboratory, repeat the relevant analysis conditions and steps in Example 1 to obtain the concentration of odorous substances and analyze the main components that cause the odor.

[0051] The analytical inlet temperature of PDMS-DVB-CAR is 300°C, and the spectra of odorous substances in this embodiment are as follows figure 2 shown.

Embodiment 3

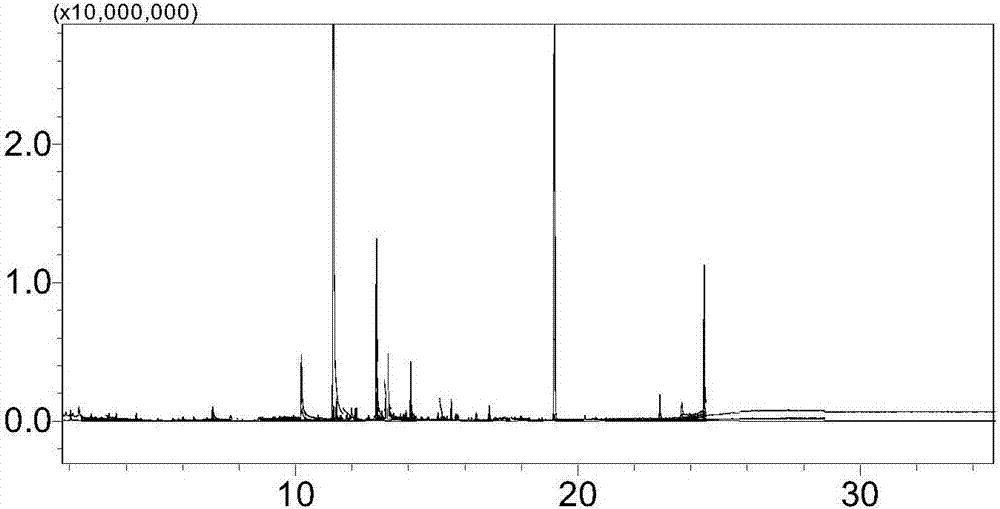

[0053] A 75 μm CAR-PDMS solid-phase microextraction fiber was used to collect fugitive odor substances emitted from pickle plants. The CAR-PDMS solid-phase microextraction fiber was aged in the inlet of the gas chromatograph before use. The aging temperature was 300°C, the volume flow rate of the carrier gas was 1.5ml / min, and the aging time was 1h. After collecting at the sampling point for 40 minutes, after transporting it back to the laboratory, repeat the relevant analysis conditions and steps in Example 1 to obtain the concentration of odorous substances and analyze the main components that cause odor. The spectrum of its odorous substances is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com