Method for determining stacking sequence of graphene sample containing single-layer graphene areas

A technology of single-layer graphene and multi-layer graphene, which is applied in the field of testing material physical property parameters, can solve the problems of stacking sequence characterization failure, SAED time-consuming, complex diffraction fringes, etc., and achieve high accuracy and enhanced strength , The effect of a simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

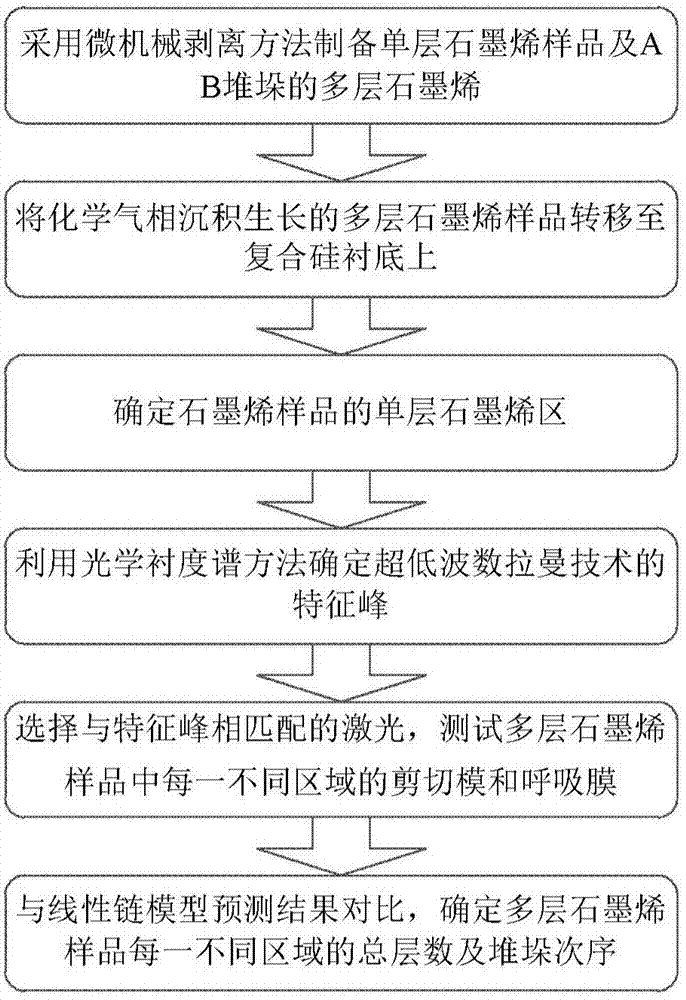

[0097] Such as figure 1 As shown, it is a flow chart of the method for determining the stacking sequence of 2-4 layers of graphene samples prepared by chemical vapor deposition proposed in this embodiment, and the method includes the following steps:

[0098] Step 1, using the micromechanical exfoliation method to prepare single-layer graphene samples and AB stacked multi-layer graphene;

[0099] i.e. on SiO 2 / Si composite silicon substrate prepared single-layer graphene samples and AB stacked multilayer graphene by micromechanical exfoliation method, composite silicon substrate SiO 2 a layer is formed over the Si layer;

[0100] Step 2, transferring the multilayer graphene sample grown by chemical vapor deposition to the composite silicon substrate;

[0101] That is to transfer the multilayer graphene sample grown by chemical vapor deposition to the same SiO 2 thickness of SiO 2 / Si composite silicon substrate;

[0102] In this step, the minimum uniform size of the lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com