Multi-LNG tank box synchronous filling system

A filling system and tank container technology, applied in the field of LNG transportation, can solve the problem of inability to synchronously and quickly fill multiple LNG tank containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

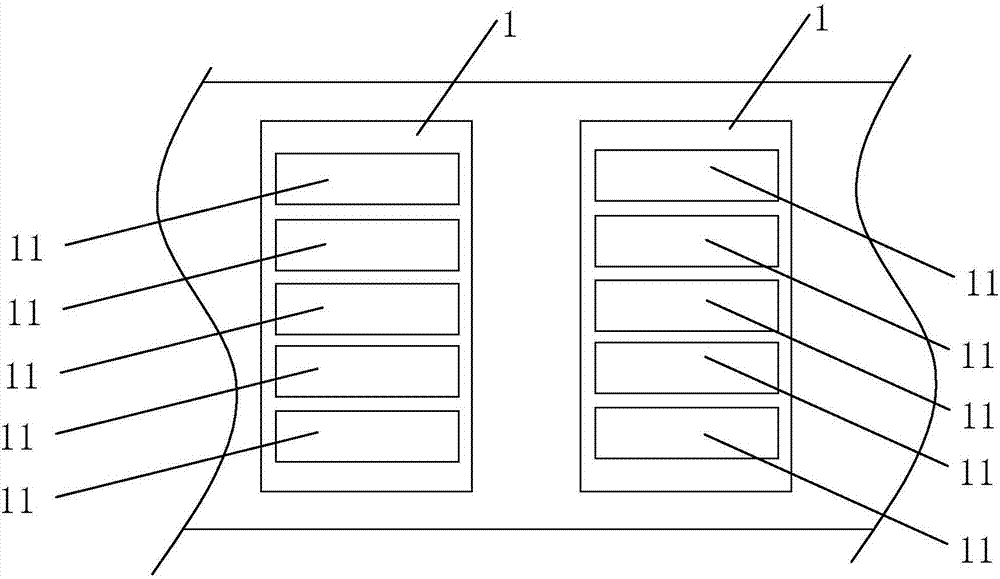

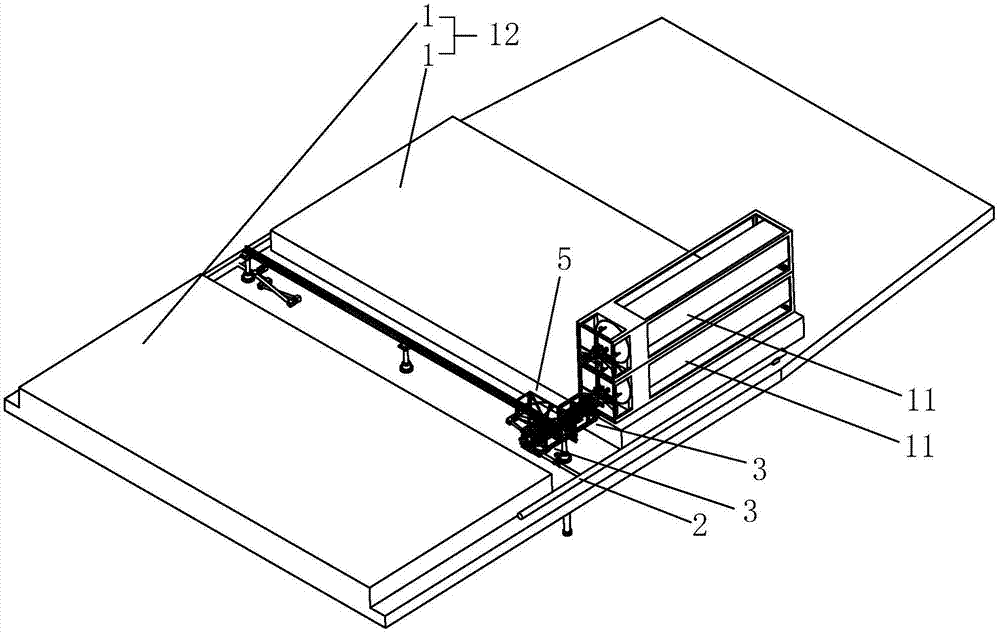

[0048] Embodiment 1: as figure 1 and figure 2 As shown, a multi-LNG tank container 11 synchronous filling system includes a plurality of LNG tank containers 11 ( figure 1 is a top view), the purpose of the present invention is to realize synchronous filling of multiple LNG tanks 11 .

[0049] Such as figure 1 and figure 2 As shown, the storage module 12 of the LNG tank 11 includes a platform 1 arranged on a plane, and the LNG tank 11 on the relative platform 1 is oppositely arranged, and the LNG tank 11 is arranged side by side along its own width direction. figure 2 In order to show clearly, the LNG tanks 11 arranged side by side are hidden); in the height direction, the LNG tanks 11 are stacked in two layers; in the length direction of the platform 1, multiple groups of LNG storage tanks can also be arranged.

[0050] Such as figure 2 As shown, the system includes a main pipe 2 for transporting LNG and returning gas, and an automatic docking device 3 for realizing a...

Embodiment 2

[0068] Embodiment 2: as Figure 11 As shown, a kind of LNG tank carrier includes a deck 7, and the multi-LNG tank synchronous filling system in Embodiment 1 is arranged on the deck 7, while the LNG storage module 12 is arranged on the deck 7, and the third oil cylinder 55 The main body can be arranged below deck 7, and the piston rod of the third oil cylinder 55 can pass through deck 7 and be positioned at deck 7 Figure 10 The lifting platform 54 described in is connected.

[0069] The working principle of embodiment 2 is the same as that of embodiment 1. The LNG receiving station or liquefaction factory wharf injects low-pressure LNG into the main pipe 2 through the crane pipe, so as to realize the synchronous filling of multiple LNG tank containers 11 on the LNG tank container transport ship. .

Embodiment 3

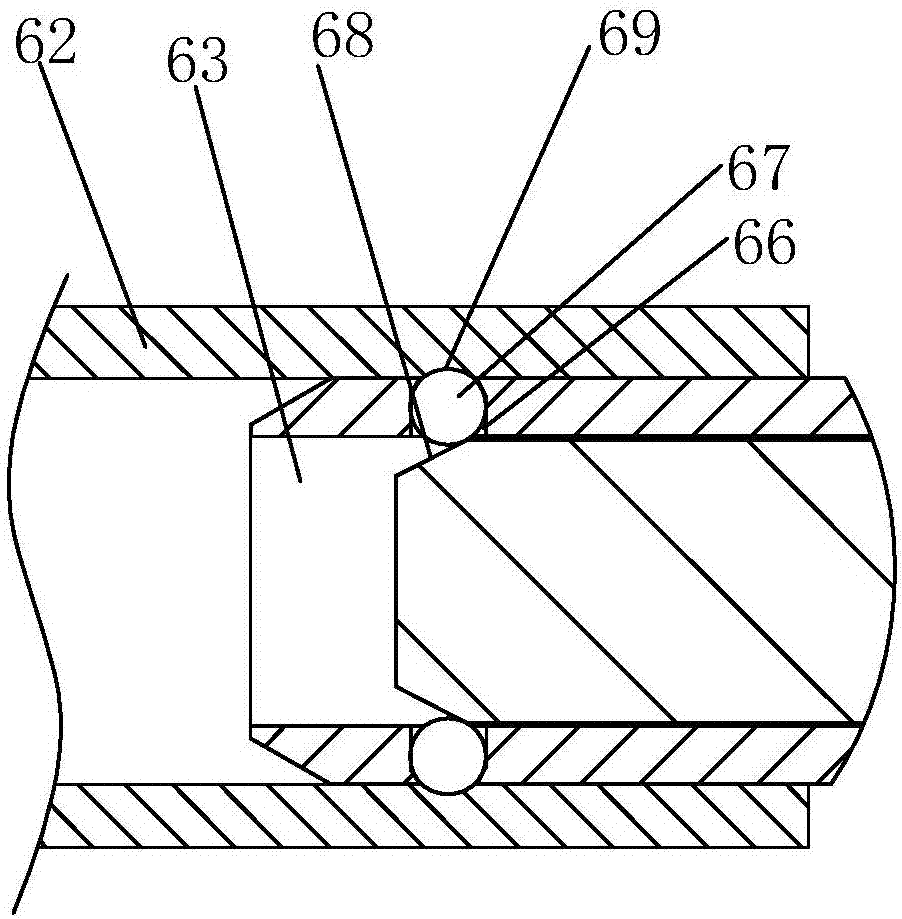

[0070] Embodiment 3: as Figure 12 as shown, Figure 11 It is a cross-sectional schematic diagram of the female filling joint 17. A vacuum temperature insulating cavity 74 is arranged in the inner wall of the female filling joint 17, and the vacuum temperature insulating cavity 74 is arranged around the female filling joint 17. By setting the vacuum temperature insulating cavity 74 , and then the low-pressure LNG at minus 100 degrees in the male filling joint 32 will not cause the outer surface of the male filling joint 32 to freeze during the filling process, so that the male filling joint 32 can be better inserted into the above-mentioned female filling Within the joint 17, the problem of wear is reduced.

[0071] A one-way valve is arranged in the female filling joint 17. When the above-mentioned male filling joint 32 is inserted into the female filling joint 17, the above-mentioned male filling joint 32 pushes the spool 71 to move backward, and the valve core 71 in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com