A kind of high temperature resistant carbon fiber sizing agent containing graphene oxide and preparation method thereof

A technology of high temperature resistance and carbon fiber, which is applied in the field of preparation of emulsion-type carbon fiber sizing agent, can solve the problems of low crosslinking density, low glass transition temperature, poor heat resistance of cured products, etc. The production and preparation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

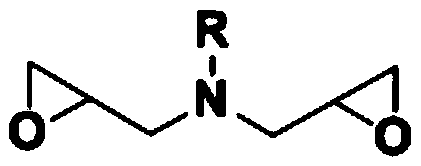

Method used

Image

Examples

example 1

[0029] Take each raw material by the following parts by mass:

[0030] 100 parts of tetraglycidyl diaminodiphenylmethane;

[0031] 20 parts of diethanolamine;

[0032] 3.3 parts of alkylphenol polyoxyethylene ether;

[0033] 9.9 parts of triphenylethylphenol polyoxypropylene polyoxyethylene block copolymer;

[0034] 12 parts of propylene glycol methyl ether;

[0035] 280 parts of graphene oxide aqueous solution;

[0036] Prepare high temperature resistant emulsion type carbon fiber sizing agent according to the following method:

[0037] Step 1) The epoxy resin tetraglycidyl diaminodiphenylmethane and diethanolamine were reacted at a constant temperature of 70° C. for 60 minutes to obtain a hydrophilic modified glycidylamine epoxy resin.

[0038] Step 2) Add the composite emulsifier, propylene glycol methyl ether of alkylphenol polyoxyethylene ether and tristyrylphenol polyoxypropylene polyoxyethylene block copolymer to the modified glycidylamine type epoxy resin obtained...

example 2

[0040] Take each raw material by the following parts by weight:

[0041] 100 parts of N,N,N',N'-tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenylmethane;

[0042] 20 parts of diethanolamine;

[0043] 3.3 parts of alkylphenol polyoxyethylene ether;

[0044] 9.9 parts of triphenylethylphenol polyoxypropylene polyoxyethylene block copolymer;

[0045] 12 parts of propylene glycol methyl ether;

[0046] 280 parts of graphene oxide aqueous solution;

[0047] Prepare high temperature resistant emulsion type carbon fiber sizing agent according to the following method:

[0048] Step 1) React epoxy resin N,N,N',N'-tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenylmethane and diethanolamine at 75°C for 60min , to obtain a hydrophilic modified glycidylamine epoxy resin;

[0049] Step 2) Add the composite emulsifier, propylene glycol methyl ether of alkylphenol polyoxyethylene ether and tristyrylphenol polyoxypropylene polyoxyethylene block copolymer to the modified glycidylamine type epo...

example 3

[0051] Take each raw material by the following parts by weight:

[0052] 100 parts of triglycidyl p-aminophenol;

[0053] 25 parts of diethanolamine;

[0054] 3.5 parts of alkylphenol polyoxyethylene ether;

[0055] 10.5 parts of triphenylethylphenol polyoxypropylene polyoxyethylene block copolymer;

[0056] 12.5 parts of ethylene glycol monoethyl ether;

[0057] 300 parts of graphene oxide aqueous solution;

[0058] Prepare high temperature resistant emulsion type carbon fiber sizing agent according to the following method:

[0059] Step 1) The epoxy resin triglycidyl p-aminophenol and diethanolamine were reacted at a constant temperature of 70° C. for 90 minutes to obtain a hydrophilic modified glycidylamine epoxy resin;

[0060] Step 2) Add the composite emulsifier of alkylphenol polyoxyethylene ether and tristyrylphenol polyoxypropylene polyoxyethylene block copolymer, ethylene glycol to the modified glycidylamine type epoxy resin obtained above. Monoethyl ether diluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com