Method for improving purity of fucoxanthin in crude extract of sargassum

A technology of fucoxanthin and sargassum, applied in the direction of organic chemistry, can solve the problems of low fucoxanthin purity and low extraction efficiency, and achieve the effects of saving production cost and production time, increasing extraction rate, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Effect of Particle Size and Water Pre-treatment on Sargassum Fucoxanthin Extraction Rate and Purity

[0033] Weigh 1 g of each of the 4 kinds of sargassum samples (over 100 mesh, over 60 mesh, about 1 mm in length, about 10 mm in length) and add 20 times the volume of deionized water (w (g) / v (ml)), soaked at room temperature for 24 hours, and suction filtered to remove polysaccharides and mannitol in Sargassum algae.

[0034] Add 20 times the volume of deionized water (w / v) to the above-mentioned sargassum from which polysaccharides and mannitol have been removed and 1 g of sargassum that has not undergone water extraction to remove polysaccharides and mannitol (over 100 mesh). , then add 100U / g cellulase and mix well, enzymatically hydrolyze at 37°C for 6 hours, and after suction filtration, place the enzymatically hydrolyzed sargassum in a dark and ventilated place to dry in the shade.

[0035] Add 30 times the volume of methanol (w / v) to the shade-dried ...

Embodiment 2

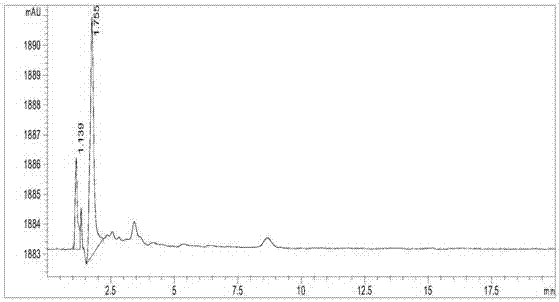

[0043] Example 2 Comparison of Fucoxanthin Extraction Rate and Purity in Different Sargassum Plant Crude Extracts

[0044] Weigh 1g each of the dried plants of 4 kinds of Sargassum family (Sargassum sargassum, sea millet, sargassum, dark-colored sargassum, and light-colored sargassum), and add deionized water 50 times the volume of the seaweed. (w / v), after soaking at room temperature for 24 hours, suction filtration to remove polysaccharides and mannitol in seaweed.

[0045] Add 20 times the volume of deionized water (w / v) to the above-mentioned groups of algae that have removed polysaccharides and mannitol, and then add 150 U / g cellulase to mix evenly, enzymatically hydrolyze at 37°C for 8 hours, and filter with suction , Place the enzymatically hydrolyzed seaweed in a dark and ventilated place to dry in the shade.

[0046] Add 50 times the volume of methanol (w / v) to the dried seaweed, extract in the dark at room temperature for 3 hours, then filter with suction, and the f...

Embodiment 3

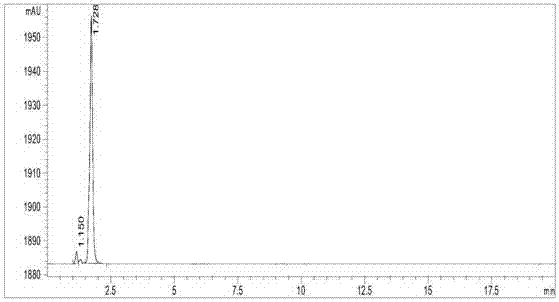

[0052] Example 3 Separation and Purification of Fucoxanthin in the Crude Extract of Sargassum Sargassum Dark

[0053] Weigh 10g of dark-colored Sargassum sargassum dry product, add deionized water (w / v) 50 times the volume of the seaweed, soak at room temperature for 48 hours, and filter with suction to remove polysaccharides and mannitol in Sargassum sargassum .

[0054] Add 20 times the volume of deionized water (w / v) to the above-mentioned Sargassum sargassum from which polysaccharides and mannitol have been removed, and then add 100 U / g cellulase, mix well, enzymolyze at 37°C for 8 hours, and filter with suction Finally, place the enzymatically hydrolyzed Sargassum sargassum in a dark and ventilated place to dry in the shade.

[0055] Add 50 times the volume of methanol (w / v) to the shade-dried Sargassum sargassum, extract in the dark at room temperature for 6 hours, then filter with suction, and the filtrate is concentrated under reduced pressure in the dark and dried in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com