Method for refining trimethylamine through extractive distillation and purification

An extractive distillation and extractive distillation tower technology, which is applied in the field of using extractive distillation to purify and purify triethylamine, can solve the problems of inability to extract and separate triethylamine, low melting temperature, etc., and achieve great implementation value and economic benefits. , The acid-base property is stable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material to be processed in this embodiment is 1000Kg / h triethylamine crude product.

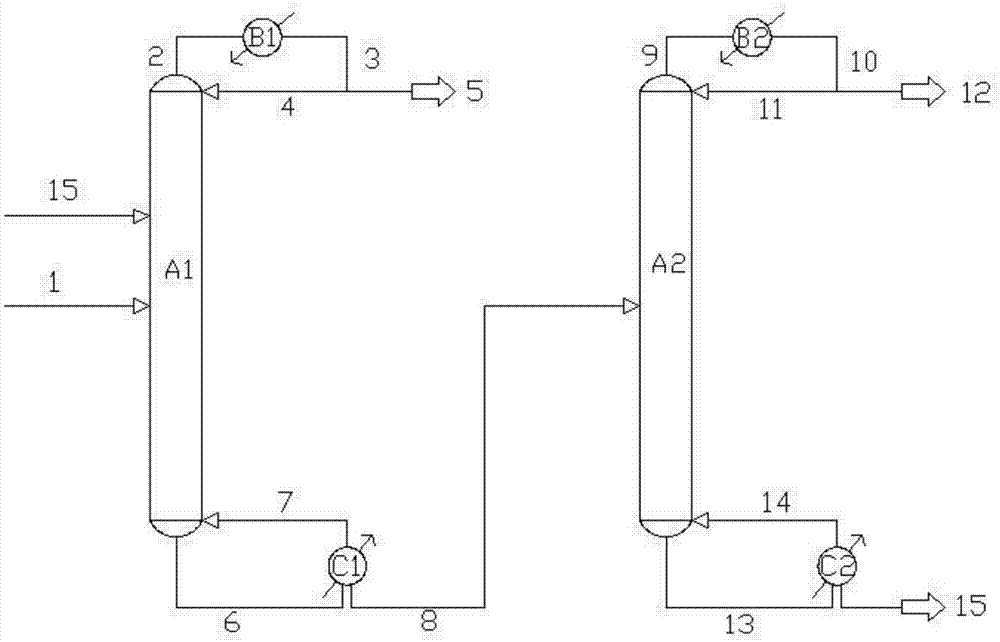

[0026] Water-containing triethylamine raw material 1 enters from the middle part of extractive distillation tower A1, and extractant 15 enters from the middle and upper part of extractive distillation tower A1. The internal working pressure of extractive distillation tower A1 is 100kPa, the number of theoretical plates is 60, and the extractant 15 The mass ratio with aqueous triethylamine raw material 1 is 4:1. The water-containing triethylamine raw material 1 and the extractant 15 in the extractive distillation tower A1 are mixed to form steam, the steam 2 in the extractive distillation tower rises to the top of the tower, enters the top condenser B1, and is condensed by the top condenser B1 to obtain a condensate 3. A part of the condensate 3 is returned to the extractive distillation column A1 as the overhead reflux to mix with the newly added raw material and the extractan...

Embodiment 2

[0029] The raw material to be processed in this embodiment is 100Kg / h triethylamine crude product.

[0030]Water-containing triethylamine raw material 1 enters from the middle part of extractive distillation tower A1, and extractant 15 enters from the middle and upper part of extractive distillation tower A1. The internal working pressure of extractive distillation tower A1 is 50kPa, the number of theoretical plates is 40, and the extractant 15 The mass ratio with aqueous triethylamine raw material 1 is 8:1. The water-containing triethylamine raw material 1 and the extractant 15 in the extractive distillation tower A1 are mixed to form steam, the steam 2 in the extractive distillation tower rises to the top of the tower, enters the top condenser B1, and is condensed by the top condenser B1 to obtain a condensate 3. A part of the condensate 3 is returned to the extractive distillation column A1 as the top reflux to mix with the newly added raw material and the extractant 15, an...

Embodiment 3

[0033] The raw material to be processed in this embodiment is 100Kg / h triethylamine crude product.

[0034] Water-containing triethylamine raw material 1 enters from the middle part of extractive distillation tower A1, and extractant 15 enters from the middle and upper part of extractive distillation tower A1. The internal working pressure of extractive distillation tower A1 is 130kPa, the number of theoretical plates is 80, and the extractant 15 The mass ratio with aqueous triethylamine raw material 1 is 1:1. The water-containing triethylamine raw material 1 and the extractant 15 in the extractive distillation tower A1 are mixed to form steam, the steam 2 in the extractive distillation tower rises to the top of the tower, enters the top condenser B1, and is condensed by the top condenser B1 to obtain a condensate 3. A part of the condensate 3 is returned to the extractive distillation column A1 as the top reflux to mix with the newly added raw material and the extractant 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com