Synthesis method and application of perfluoro(2-methyl-3-pentanone)

A technology of perfluorohexanone and a synthesis method is applied in the field of synthesis of perfluorohexanone, and can solve the problems of complex production process of perfluorohexanone, influence on the purity of perfluorohexanone finished product, low relative volatility of perfluorohexanone, etc. , to achieve the fire-extinguishing effect of green environmental protection, good fire-extinguishing effect, and the effect of improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

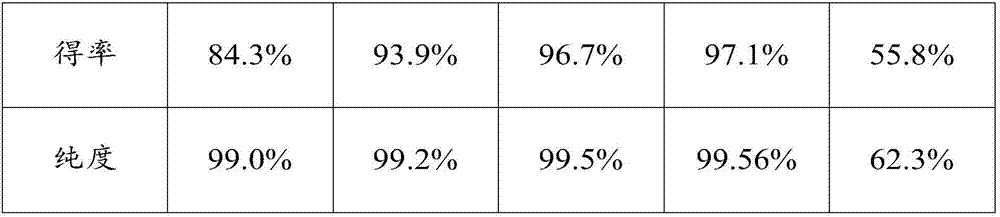

Examples

preparation example Construction

[0018] The synthesis method of perfluorohexanone in this embodiment may include the following steps: mixing hexafluoropropylene dimer with a solvent, cooling to 13-17° C., adding an oxidizing agent, performing an oxidation reaction, and collecting the reaction product with the largest specific gravity. Preferably, the substances in the oxidation reaction can be statically separated and separated, and the lower layers are collected to obtain perfluoroepoxides.

[0019] As an option, the above-mentioned solvent may be selected from at least one of aprotic polar solvents, such as acetonitrile and dimethylformamide. The oxidizing agent includes hypochlorite solution, preferably, the hypochlorite solution may include sodium hypochlorite solution and calcium hypochlorite solution. The mass concentration of active chlorine in the hypochlorite solution is 8-12%, so that the hexafluoropropylene dimer can be fully oxidized.

[0020] Preferably, sodium hypochlorite solution is used as t...

Embodiment 1

[0039] Mix 90 kg of acetonitrile, 3 kg of tetramethylethylenediamine, and 1 kg of a mixture of sodium fluoride and cesium fluoride, blow in nitrogen gas, and react with stirring at 35° C. for 1.2 h to obtain a yellow catalyst solution. Then add 18 kilograms of hexachloropropene per hour in the catalyst solution, adding 90 kilograms of hexachloropropene in total. React under the conditions of 30°C and 0.1MPa, stand still for 6min every 0.8h, collect the lower layer, and obtain a hexafluoropropylene dimer containing perfluoro-2-methyl-2-pentene with a purity of 88%.

[0040] Add 250 kg of the above-mentioned hexafluoropropylene dimer and 40 kg of dimethylformamide into the reaction kettle, stir and cool to 13°C, then add 500 kg of calcium hypochlorite solution dropwise for 7.5 hours . Wherein, the mass concentration of active chlorine contained in the calcium hypochlorite solution is 8%. Adjust the temperature of the reaction system after adding the calcium hypochlorite soluti...

Embodiment 2

[0043] Mix 100 kilograms of acetonitrile, 5 kilograms of tetramethylethylenediamine and 3 kilograms of potassium hydrofluoride, phosphorus pentafluoride and sulfur tetrafluoride mixture, feed nitrogen, and stir the reaction at 45 ° C for 0.8 h, to obtain a yellow catalyst solution. Then add 22 kilograms of hexachloropropene per hour in the catalyst solution, adding 110 kilograms of hexachloropropene in total. React under the conditions of 40°C and 0.15MPa, stand still for 4min every 1.2h, collect the lower layer, and obtain a hexafluoropropylene dimer containing perfluoro-2-methyl-2-pentene with a purity of 90%.

[0044] Add 130 kg of the above-mentioned hexafluoropropylene dimer to the reactor, then add 90 kg of acetonitrile and dimethylformamide mixture, 3 kg of 15-crown-5 amine and 0.8 kg of powdered potassium fluoride , The reaction was stirred at 40° C. for 15 h. After standing still for 15 min, the lower layer was collected to obtain perfluoro-2-methyl-2-pentene with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com