Diamond wire cutting machine and diamond wire replacing method thereof

A technology of cutting machine and gold wire, applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems that the cutting process cannot be guaranteed to be continuous, uneven tension of the working wire mesh, and line marks on the cutting surface. , to achieve the effect of improving continuity, ensuring uniformity and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

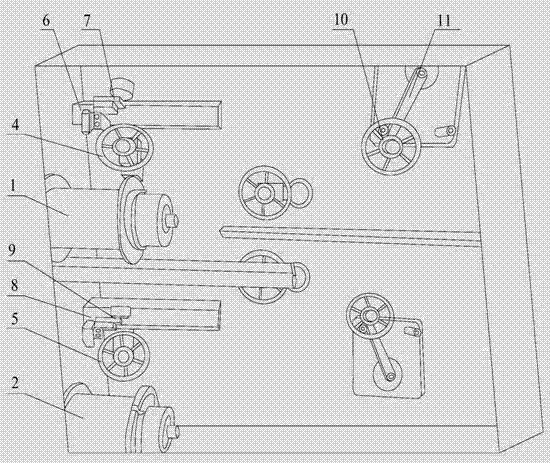

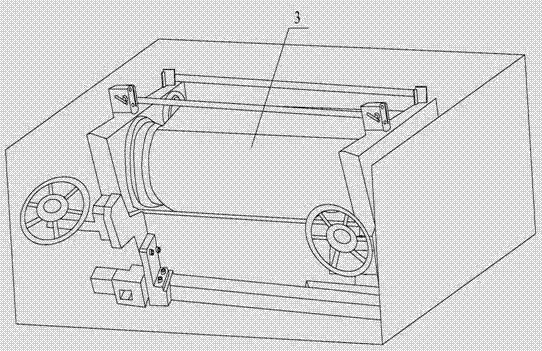

[0041] Combined with the manual figure 1 — figure 2, a gold wire cutting machine and a method for replacing steel wires thereof in the present invention, comprising a pay-off reel 1, a take-up reel 2, and a main roller 3, and the input end of the main roller 3 is sequentially connected to the pay-off reel 1, the second reel through a steel wire A row of wire pulleys 4 and a plurality of guide pulleys, the output end of the main roller 3 is sequentially connected to a plurality of guide pulleys, the second wire arrangement pulley 5 and the take-up pulley 2 through steel wires, and the surface of the main roller 3 is wound with multiple A set of parallel steel wires, the pay-off length of the pay-off wheel 1 is at least 100m longer than the sum of the length of the steel wire wound on the surface of the main roller 3 and the length of the maximum advancing wire when the main roller 3 is in the cutting process state. Wherein the first reel 4 is equipped with a first reciprocati...

Embodiment 2

[0044] Combined with the manual figure 1 — image 3 , a gold wire cutting machine and a method for replacing steel wires thereof in the present invention, comprising a pay-off reel 1, a take-up reel 2, and a main roller 3, and the input end of the main roller 3 is sequentially connected to the pay-off reel 1, the second reel through a steel wire A row of wire pulleys 4 and a plurality of guide pulleys, the output end of the main roller 3 is sequentially connected to a plurality of guide pulleys, the second wire arrangement pulley 5 and the take-up pulley 2 through steel wires, and the surface of the main roller 3 is wound with many A set of parallel steel wires, the pay-off length of the pay-off wheel 1 is at least 100m longer than the sum of the length of the steel wire wound on the surface of the main roller 3 and the length of the maximum advancing wire when the main roller 3 is in the cutting process state. Wherein the first reel 4 is equipped with a first reciprocating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com