Method for preparing nanofiltration/forward osmosis amphibious performance CTA membrane and apparatus thereof

A technology of forward osmosis and nanofiltration, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of imperfect forward osmosis membrane technology, and achieve environmental friendliness, simple preparation method, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

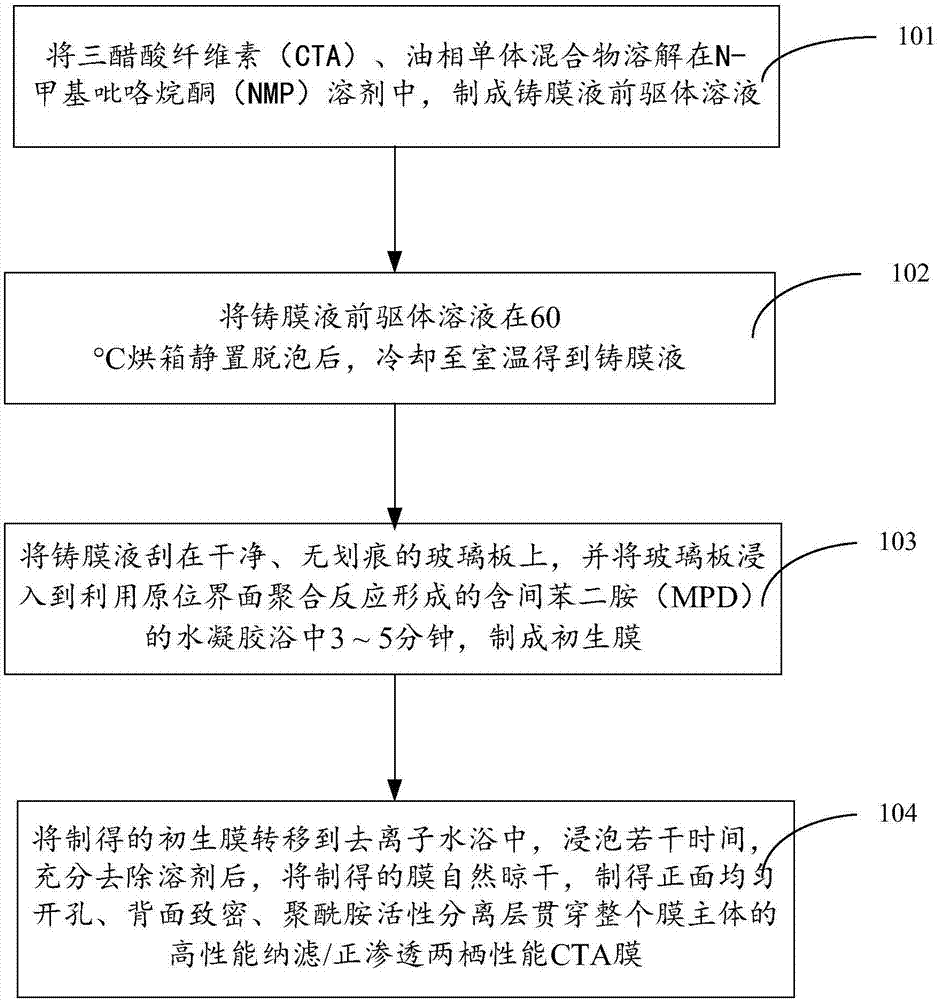

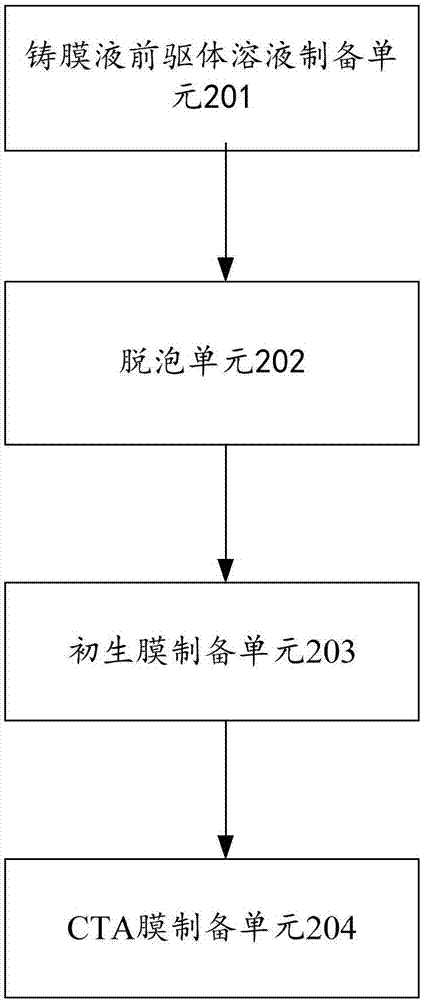

[0054] Step (1), 13.0g cellulose triacetate and oil phase monomer mixture are dissolved in NMP solvent, make film-forming precursor solution;

[0055] The mass fraction of the oil phase monomer in the film-forming precursor solution is 0.1%;

[0056] In step (2), the casting solution is placed in a 60°C water bath, and after mechanical stirring for 12 hours, the casting solution is left to defoam in an oven at 60°C for 8 hours, and then cooled to room temperature;

[0057] Step (3), scrape the casting solution on a clean, dry, non-scratched glass plate, immerse in a solution with a m-phenylenediamine content of 0.1%, and form a film in the gel phase separation;

[0058] In step (4), the formed nascent film was immersed in a deionized water bath at 25° C. for 7 days, and the water was changed three times a day. The prepared membrane is placed in the air and dried naturally at room temperature to obtain a structurally regulated nanofiltration / forward osmosis amphibian CTA membr...

Embodiment 2

[0064] Step (1), 13.0g cellulose triacetate and oil phase monomer mixture are dissolved in NMP solvent, make film-forming precursor solution;

[0065] The mass fraction of the oil phase monomer in the above precursor solution is 0.1%;

[0066] In step (2), the casting solution is placed in a 60°C water bath, and after mechanical stirring for 12 hours, the casting solution is left to defoam in an oven at 60°C for 8 hours, and then cooled to room temperature;

[0067] Step (3), scrape the casting solution on a clean, dry, non-scratched glass plate, immerse in a solution with a m-phenylenediamine content of 0.2%, and form a film in the gel phase separation;

[0068] In step (4), the formed nascent film was immersed in a deionized water bath at 25° C. for 7 days, and the water was changed three times a day. The prepared membrane is placed in the air and dried naturally at room temperature to obtain a structurally regulated nanofiltration / forward osmosis amphibian CTA membrane.

...

Embodiment 3

[0073] Step (1), 13.0g cellulose triacetate and oil phase monomer mixture are dissolved in NMP solvent, make film-forming precursor solution;

[0074] The mass fraction of the oil phase monomer in the above precursor solution is 0.15%;

[0075] In step (2), the casting solution is placed in a 60°C water bath, and after mechanical stirring for 12 hours, the casting solution is left to defoam in an oven at 60°C for 8 hours, and then cooled to room temperature;

[0076] Step (3), scrape the casting solution on a clean, dry, non-scratched glass plate, immerse in a solution with a m-phenylenediamine content of 0.1%, and form a film in the gel phase separation;

[0077]In step (4), the formed nascent film was immersed in a deionized water bath at 25° C. for 7 days, and the water was changed three times a day. The prepared membrane is placed in the air and dried naturally at room temperature to obtain a structurally regulated nanofiltration / forward osmosis amphibian CTA membrane.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com