High-nutrition slowly digestible buckwheat powder and preparation method thereof

A technology of buckwheat flour and slow digestion, applied in the field of biological enzymolysis and food processing, can solve the problems of inability to fundamentally make up for nutritional deficiencies, easy extraction process, reagent residue, etc., to eliminate allergens, facilitate industrial production, The effect of changing the degree of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high-nutrition slow-digesting buckwheat flour, the preparation method of the buckwheat flour comprises the following specific steps:

[0027] (1) Take by weighing 35 grams of tartary buckwheat flour (80 orders, moisture content 13.47%) and mix with water, be mixed with the starch milk that mass fraction is 35%;

[0028] (2) Adjust the pH value to 11, add 100U of alkaline protease (enzyme activity 20000U / g), and hydrolyze in a water bath at 60°C for 40min;

[0029] (3) Add 0.1mol / mL H 2 SO 4 Adjust the pH value of the starch milk to 7.0, and gelatinize in a boiling water bath for 30 minutes;

[0030] (4) Cool the gelatinized product to room temperature and store it in a refrigerator at 4°C for 4 days. The product is centrifuged and freeze-dried to obtain

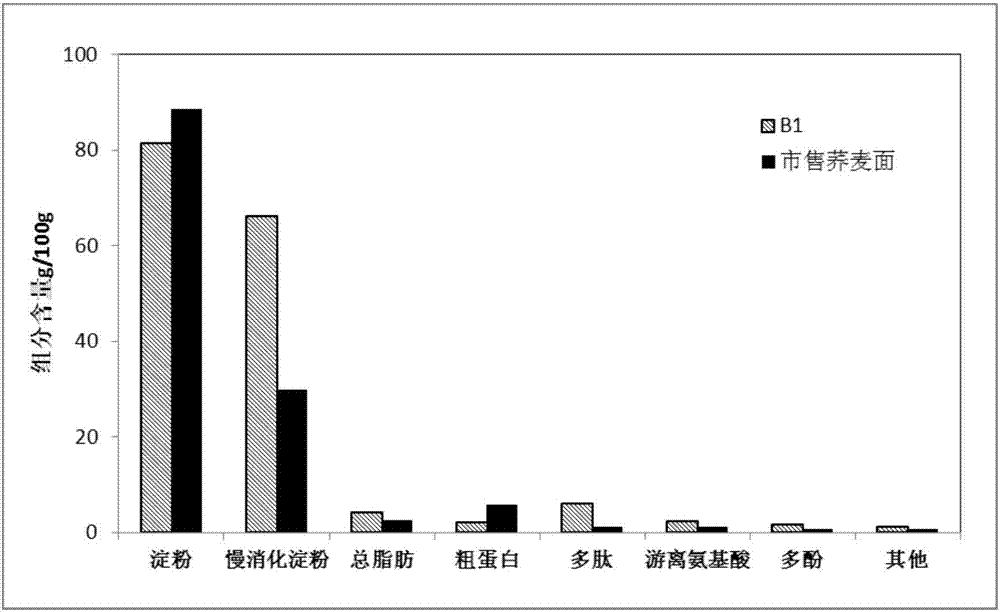

[0031] The nutritional components of high-nutrient slow-digesting buckwheat flour B1 and commercially available buckwheat flour were compared.

[0032] The refrigerating process described in step (4) needs to be ...

Embodiment 2

[0036] A high-nutrition slow-digesting buckwheat flour, the preparation method of the buckwheat flour comprises the following specific steps:

[0037] (1) Take by weighing 50 grams of sweet buckwheat flour (120 orders, moisture content 12.97%) and mix with water, homogenate, be mixed with the starch milk that mass fraction is 15%;

[0038] (2) Adjust the pH to 5, add 200U trypsin (enzyme activity 3000U / g), and put it in a 40°C water bath for 30min;

[0039] (3) Add 0.01mol / mL sodium hydroxide to adjust the pH value of the starch milk to 6.5, and gelatinize in a boiling water bath for 40 minutes;

[0040] (4) The gelatinized product was cooled to room temperature and stored in a refrigerator at 4°C for 6 days. The product was centrifuged and freeze-dried to obtain high-nutrition slow-digesting buckwheat flour B2.

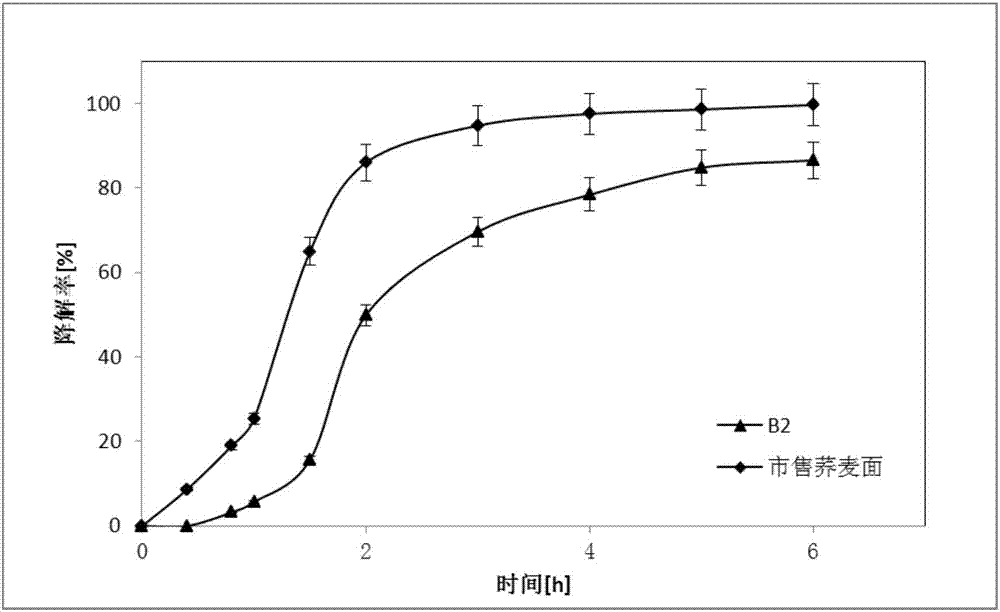

[0041]According to the running time of the food in the human body, the in vitro degradation process of the high-nutrition slow-digesting buckwheat flour obtained in...

Embodiment 3

[0044] A high-nutrition slow-digesting buckwheat flour, the preparation method of the buckwheat flour comprises the following specific steps:

[0045] (1) Take by weighing 100 grams of tartary buckwheat flour (200 mesh, moisture content 13.76%) and 20 grams of sweet buckwheat flour (moisture content 12.97%) and mix with water, homogenate, be mixed with the starch milk (w / w);

[0046] (2) Adjust the pH to 8, add 3000U papain (enzyme activity 100000U / g), and hydrolyze in a water bath at 55°C for 35min;

[0047] (3) Add 0.1mol / mL H 2 SO 4 Adjust the pH value of the starch milk to 7.0, and gelatinize in a boiling water bath for 1 hour;

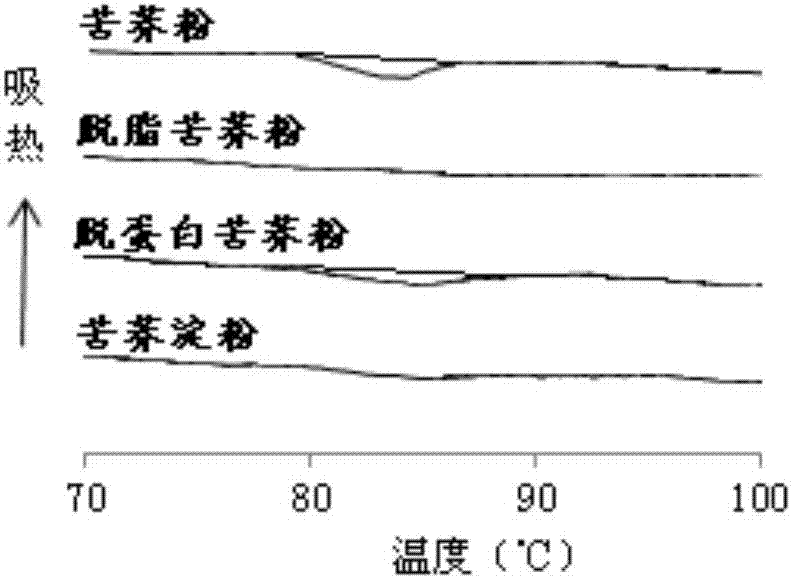

[0048] (4) Cool the gelatinized product to room temperature and store it in a refrigerator at 4°C for 3 days. The product is centrifuged and freeze-dried to obtain high-nutrition slow-digesting buckwheat flour B3. The thermal analysis results are as follows: image 3 shown.

[0049] image 3 It is the DSC measurement figure of untreated tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com