Fermentation method for preparing Chinese wolfberry active peptide, method, application, inhibitor and functional food

A technology for functional foods and active peptides, applied in the preparation methods of peptides, enzyme inhibitor components, biochemical equipment and methods, etc., can solve problems such as liver and kidney burden, side effects, etc. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of wolfberry protein extract

[0023] Using 10g of dried wolfberry as raw material, weigh wolfberry and add 100mL of deionized water to soak for 2 hours, then pulverize, ultrasonically extract for 60min, centrifuge at 5000rpm for 10min, and 9.6g of precipitate is used to extract wolfberry protein.

[0024] After precipitation and freeze-drying, pulverize again to obtain wolfberry powder, add 192mL of organic solvent extract to the wolfberry powder, n-hexane:ethanol=2.6:1 (v / v), stir and extract at a temperature of 50°C and a rotating speed of 150rpm for 1 hour, filter, filter The cake is extracted once with the same organic solvent extract as above, filtered twice after extraction, and the filter cake is 7.5g wolfberry protein after freeze-drying.

[0025] (2) Preparation of wolfberry active peptide

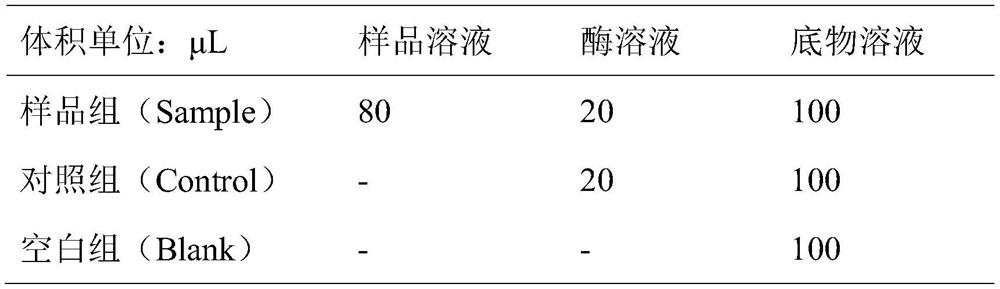

[0026] Add wolfberry protein to 112mL ionized water, adjust the pH to 7.5 with 1M sodium hydroxide solution, inoculate microbial strains (Bacillus subtili...

Embodiment 2

[0029] Lycium barbarum protein is extracted, and wolfberry active peptide is prepared through microbial fermentation of wolfberry protein.

[0030] (1) Preparation of wolfberry protein extract

[0031] Using 20g of dried wolfberry as raw material, weigh wolfberry and add 40mL of deionized water to soak for 2 hours, then pulverize, ultrasonically extract for 20min, and centrifuge at 7000rpm for 10min to obtain 19.1g of precipitate for extracting wolfberry protein.

[0032] After precipitation and freeze-drying, pulverize again to obtain wolfberry powder, add 97.5mL of organic solvent extract to the wolfberry powder, ethyl acetate:methanol=1:1 (v / v), stir and extract at a temperature of 20°C and a rotating speed of 80rpm for 0.5 hours, extract Filter once, and the filter cake is 15g wolfberry protein after freeze-drying.

[0033] (2) Preparation of wolfberry active peptide

[0034] Add wolfberry protein to 75mL deionized water, adjust the pH to 7.5 with 1M sodium hydroxide sol...

Embodiment 3

[0037] Lycium barbarum protein is extracted, and wolfberry active peptide is prepared through microbial fermentation of wolfberry protein.

[0038] (1) Preparation of wolfberry protein extract

[0039] Using 30g of dried wolfberry as raw material, weigh wolfberry and add 120mL of deionized water to soak for 2 hours, then pulverize, ultrasonically extract for 40min, centrifuge at 5000rpm for 15min, and 28.7mL of precipitate is used to extract wolfberry protein.

[0040] After precipitation and freeze-drying, crush again to obtain wolfberry powder, add 143.5mL of organic solvent extract to the wolfberry powder, ethyl acetate:methanol=1:4 (v / v), stir and extract at a temperature of 20°C and a speed of 80rpm for 0.5 hours, filter , the filter cake is extracted once with the same organic solvent extract as above, filtered after extraction twice, and the filter cake is 22.67g wolfberry protein after freeze-drying.

[0041] (2) Preparation of wolfberry active peptide

[0042] Add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com