Control method based on combination of combined integral controllers and dual control system

A combined integral and dual control technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as insufficient control performance, and achieve good robust performance, fast response, and small overshoot Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention.

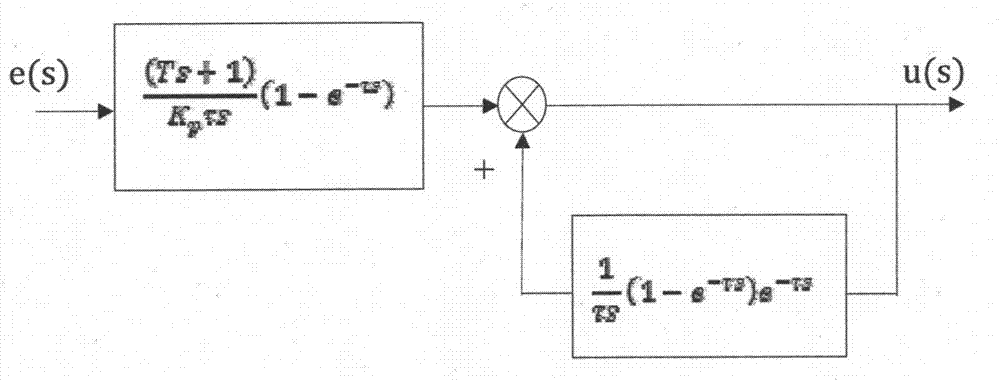

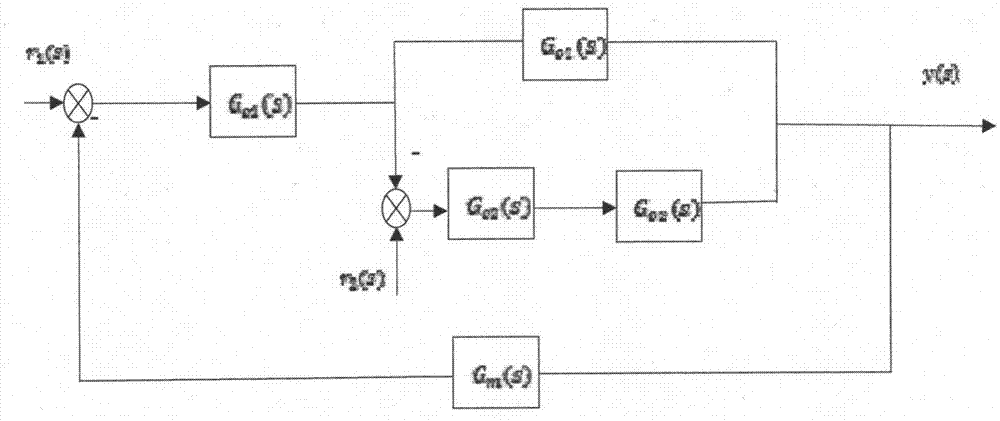

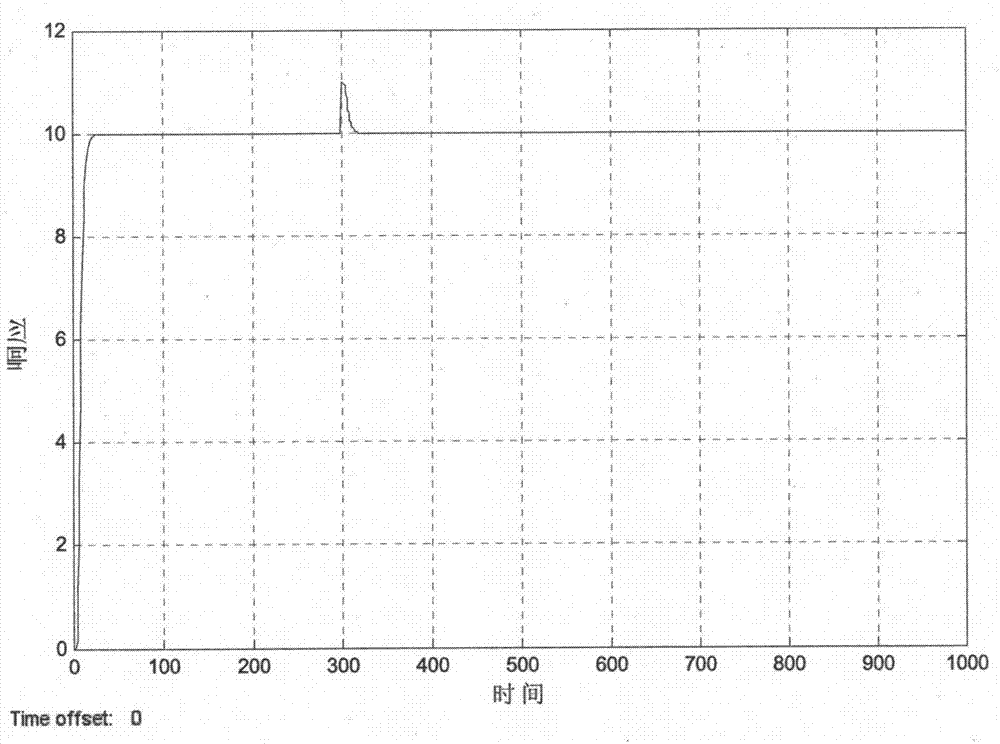

[0021] The invention provides a control method combining a combined integral controller and a dual control system. The control method uses the combined integral controller for the control of the fast and slow response loops in the dual control system to replace the traditional PID controller originally used. . The traditional PID controller originally applied to the fast and slow response loop control in the dual control system, when dealing with the controlled object with large lag and strong nonlinearity, the system response time is long, the overshoot is serious, the steady-state error is large, and the system Without reaching a stable state, its control performance is difficult to adapt to the actual needs of the process industry. For example, in the drying process of the tobacco industry, this control scheme will cause the temperature of the system to fluctuate up and down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com