Method for online detecting and evaluating online cut tobacco mixing uniformity of cigarette

An evaluation method and uniformity technology, which is applied in the fields of tobacco, measuring devices, and tobacco preparation, can solve the problems of lack of online blending uniformity detection and evaluation methods, blending level, lack of online blending uniformity, etc., and achieve good results. The effect of practical value and promotion and application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

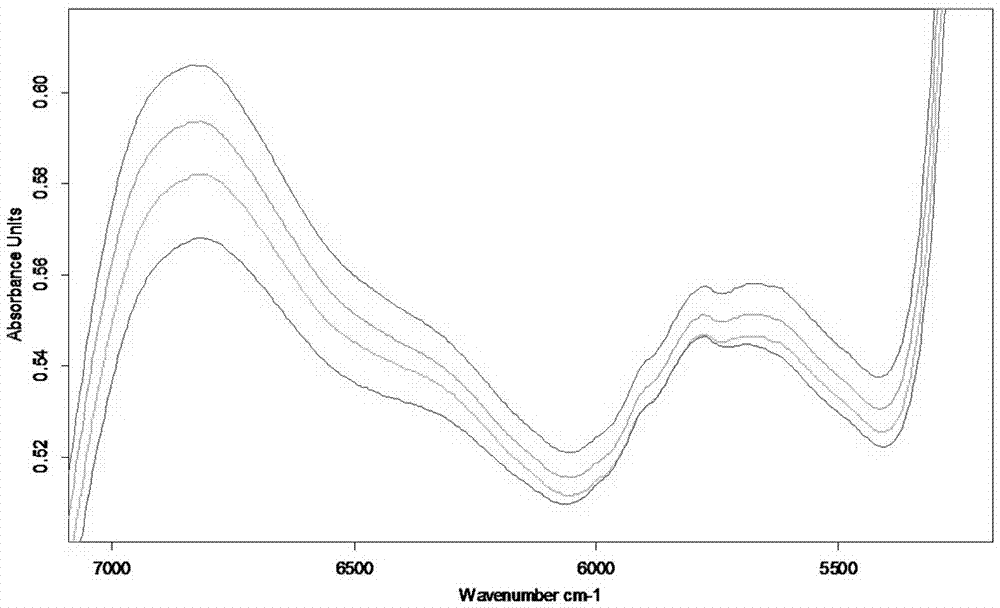

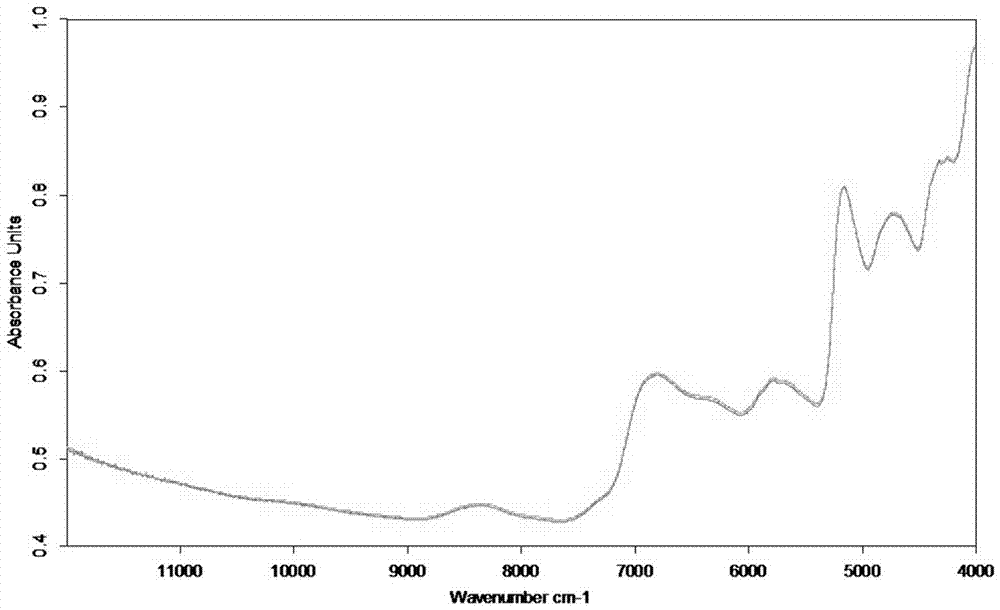

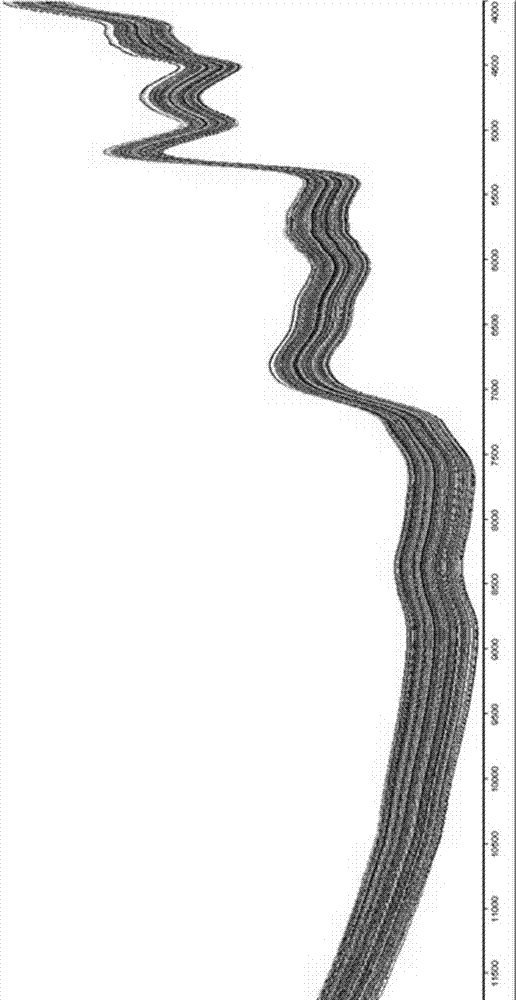

[0059] The method for detecting and evaluating the uniformity of mixed shredded cigarettes on-line made by this application is based on the principle that the sugar-alkaline ratio in online shredded tobacco can better reflect the internal quality of tobacco, and is established by using the difference in the sugar-alkaline ratio of online shredded tobacco. On-line uniform evaluation method; the specific operation steps are detailed as follows.

[0060] (1) Preparation of modeling samples

[0061] The shredded tobacco and expanded cut stems were sampled separately after online drying, and the simulated shredded tobacco was prepared by gradient ratio of shredded tobacco and expanded cut stems, which were used as the samples required for modeling; specifically, the operation method refers to the following:

[0062] Sampling method of shredded tobacco after on-line shredded drying: when the shredded shredded drying process runs normally for no less than 10 minutes, start sampling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com