All-intelligence ground scale preventing and removing machine

A technology of anti-scaling and descaling and descaling device, which is applied in the direction of descaling and water softening, chemical instruments and methods, special treatment targets, etc., and can solve problems such as insufficient orifice plate processing capacity, poor safety performance, and complicated pipelines , to achieve the effect of continuous current release performance enhancement, not easy to lose electrons, and stable current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

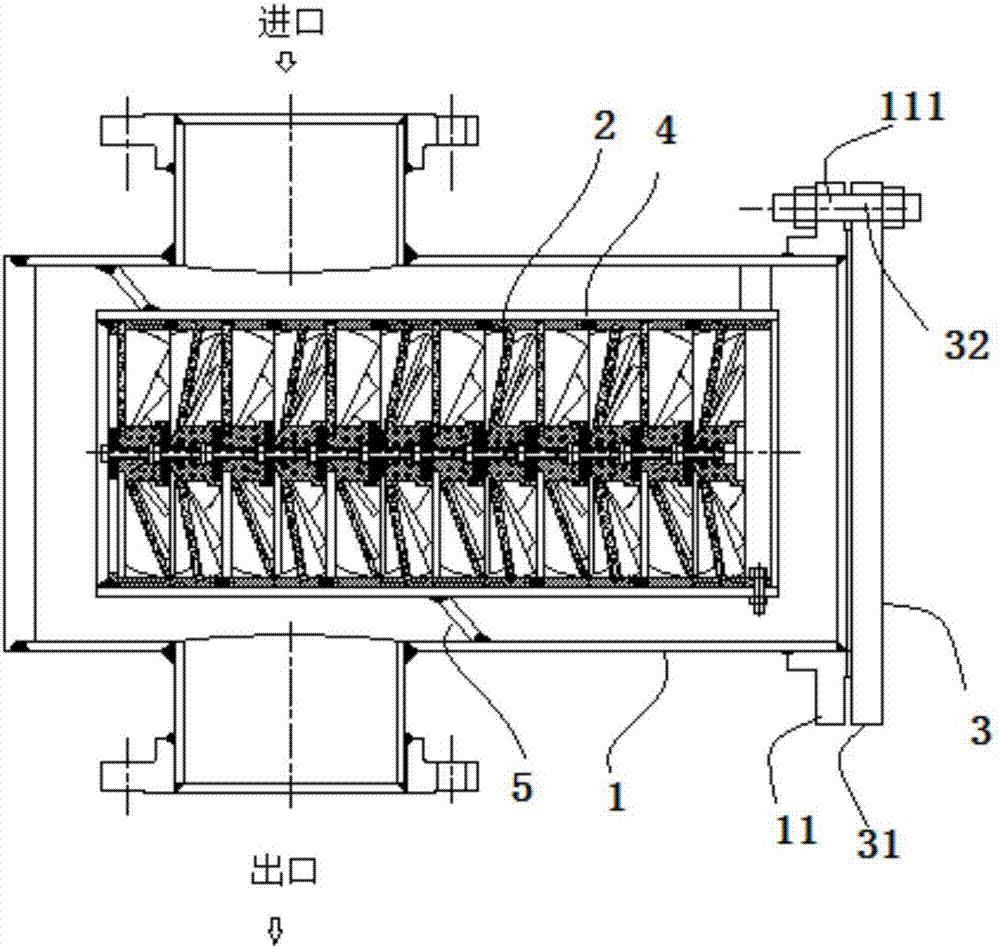

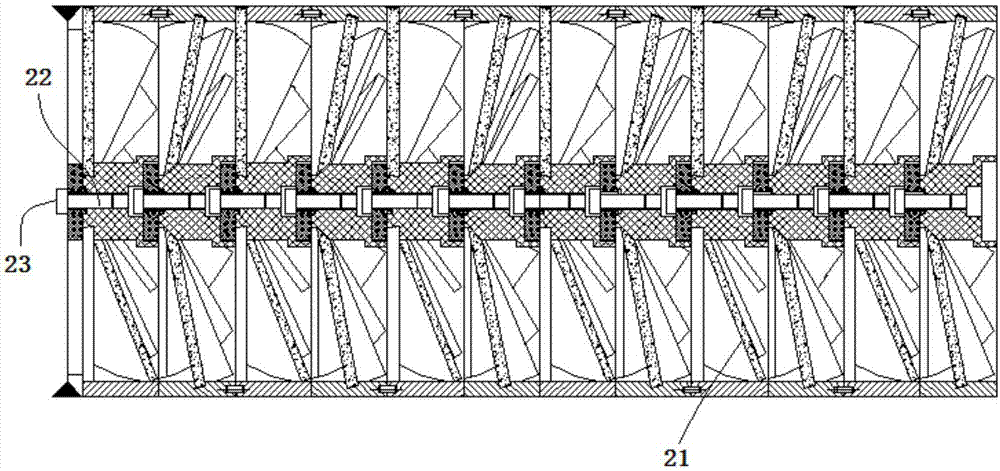

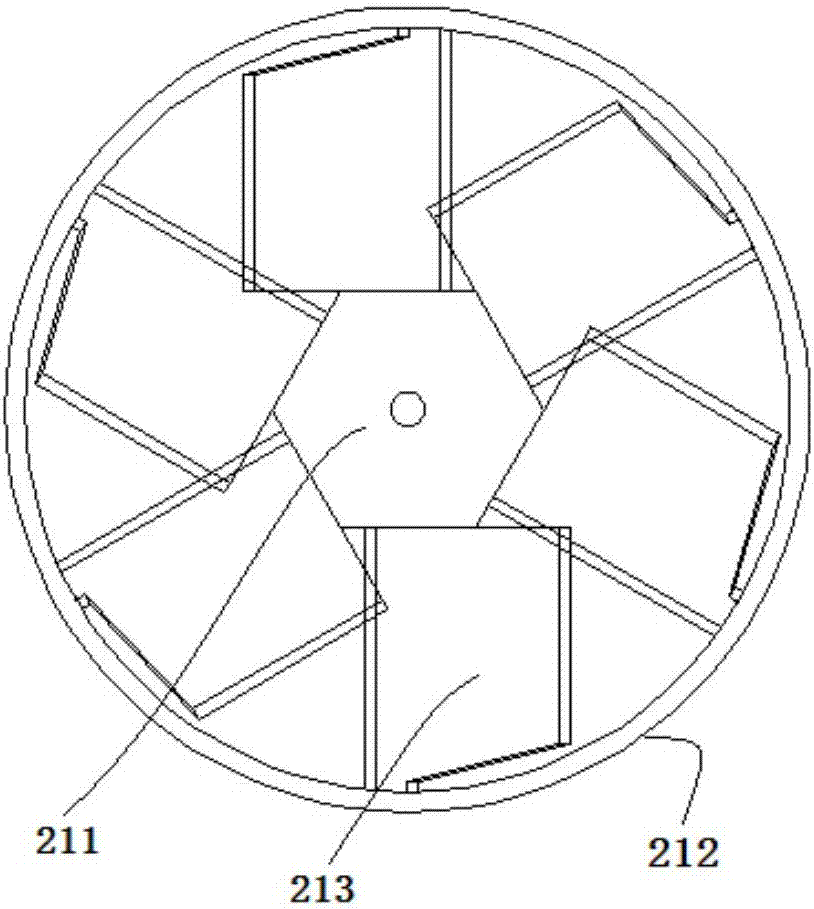

[0026] like Figure 1-5 As shown, the fully intelligent ground anti-scaling and descaling device of the present invention includes an anti-scaling pipe 1, an anti-scaling body 2 and a pipe joint, the anti-scaling body 2 is arranged in the anti-scaling pipe 1, and the pipe joint is installed in the anti-scaling pipe 1, fix the anti-scaling body 2 in the anti-scaling pipe 1.

[0027] The anti-scaling pipe 1 is a "T"-shaped three-way pipe structure, wherein the lower end of the "T" is connected to the pipe joint 3, and the left and right ends of the "T" are respectively an outlet and an inlet. There is a cavity hole in the anti-scaling pipe 1, which is used to install the anti-scaling body 2. There is a baffle 5 between the outer wall of the cavity hole 4 and the inner wall of the anti-scaling pipe 1. The baffle 5 at the entrance is located near the "T" at the entrance. At the upper end of the "T" shape, it is blocked to prevent the fluid entering the inlet from flowing toward the...

Embodiment 2

[0032] The difference between this embodiment and Example 1 is that the composition ratio of the fully intelligent anti-scaling and descaling alloy is different. The fully intelligent anti-scaling and descaling alloy in this embodiment includes the following components by mass percentage: Cu: 45%-65%, Ni: 10%-20%, Zn: 10%-20%, Sn: 7%-30%, Ag: 2%-20%, Fe: 2%-8%, Nb: 0.01%-2%, Mn: 0.05%-5%, V: 0.01%-2%, C: 0.01%-0.5%, said components are smelted at high temperature to form a columnar crystal alloy that grows oriented along the S110 crystal axis.

Embodiment 3

[0034] The difference between this embodiment and Example 1 is that the composition ratio of the fully intelligent anti-scaling and descaling alloy is different. The fully intelligent anti-scaling and descaling alloy in this embodiment includes the following components by mass percentage: Cu: 50%-60%, Ni: 12%-18%, Zn: 10%-15%, Sn: 7%-10%, Ag: 2%-8%, Fe: 2%-6%, Nb: 0.01%-2%, Mn: 0.05%-5%, V: 0.01%-2%, C: 0.01%-0.2%, said components are smelted at high temperature to form a columnar crystal alloy that grows oriented along the S110 crystal axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com