Viscosity-reducing oil displacement agent for common heavy oil reservoirs, and preparation method thereof

A technology for heavy oil reservoirs and viscous oil displacement agents, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problem that the polymer has a limited effect of increasing the viscosity of the water phase, and it is difficult to meet the needs of efficient development. Solution viscosity reduction and other problems, to achieve good compatibility, improve the water-oil mobility ratio, reduce the viscosity of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

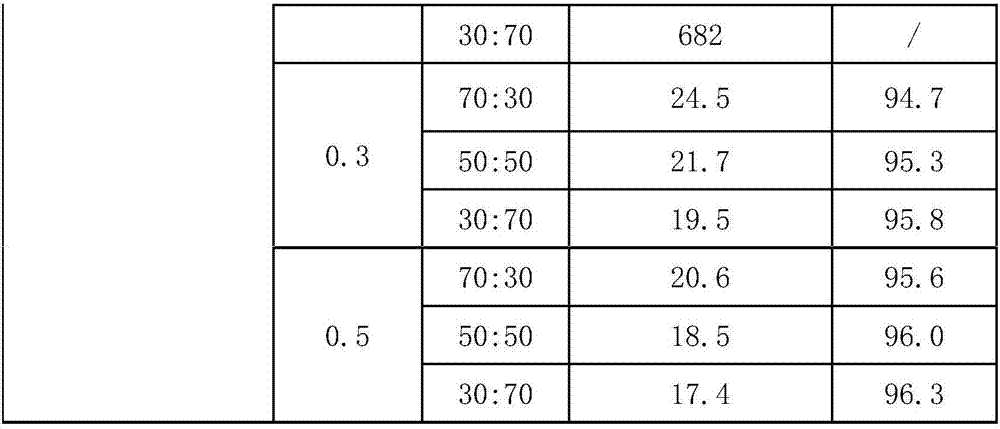

Examples

Embodiment 1

[0023] Embodiment 1 prepares viscosity reducing oil displacement agent

[0024] The components are: 50kg of alkyl alcohol polyoxyethylene ether sulfate salt, 5kg of sorbitol polyoxyethylene ether, 5kg of fatty alcohol polyoxyethylene ether, 5kg of sorbitan fatty acid ester, 7kg of sodium cetyl sulfate, ten Sodium dialkylbenzene sulfonate 8kg, isopropanol 3kg, sodium chloride 1kg, water 16kg.

[0025] Proceed as follows:

[0026] (1) Under normal temperature and pressure, sorbitol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, sorbitan fatty acid ester, isopropanol, 8kg (50% of total water) water are added to reactor, fully Stir for 2 hours;

[0027] (2) Add cetyl sodium sulfate and sodium dodecylbenzenesulfonate to the above reaction kettle, and after stirring for 1 hour, add the remaining 8kg of water, and evenly add sodium chloride powder, stir until uniform, and form an auxiliary agent ;

[0028] (3) Put the alkyl alcohol polyoxyethylene ether sulfate into ...

Embodiment 2

[0029] Embodiment 2 prepares viscosity reducing oil displacement agent

[0030] The components are: 40kg of alkyl alcohol polyoxyethylene ether sulfate salt, 25kg of fatty alcohol polyoxyethylene ether, 5kg of sodium cetyl sulfate, 5kg of sodium dodecyl sulfate, 5kg of sodium dodecylbenzenesulfonate, Ethylene glycol 2kg, sodium chloride 1kg, water 17kg.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3 prepares viscosity reducing oil displacement agent

[0033] The components are: alkyl alcohol polyoxyethylene ether sulfate 45kg, sorbitol polyoxyethylene ether 10kg, fatty alcohol polyoxyethylene ether 10kg, cetyl sodium sulfate 5kg, lauryl sodium sulfate 5kg, dodecyl sodium sulfate Sodium alkylbenzene sulfonate 5kg, sodium stearate 5kg, ethylene glycol 3kg, sodium chloride 2kg, water 10kg.

[0034] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com