Kiln device for melting heating of glass

A glass melting and furnace technology, applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve problems such as poor thermal shock resistance, easy electrical corrosion, and uneven temperature distribution of glass liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

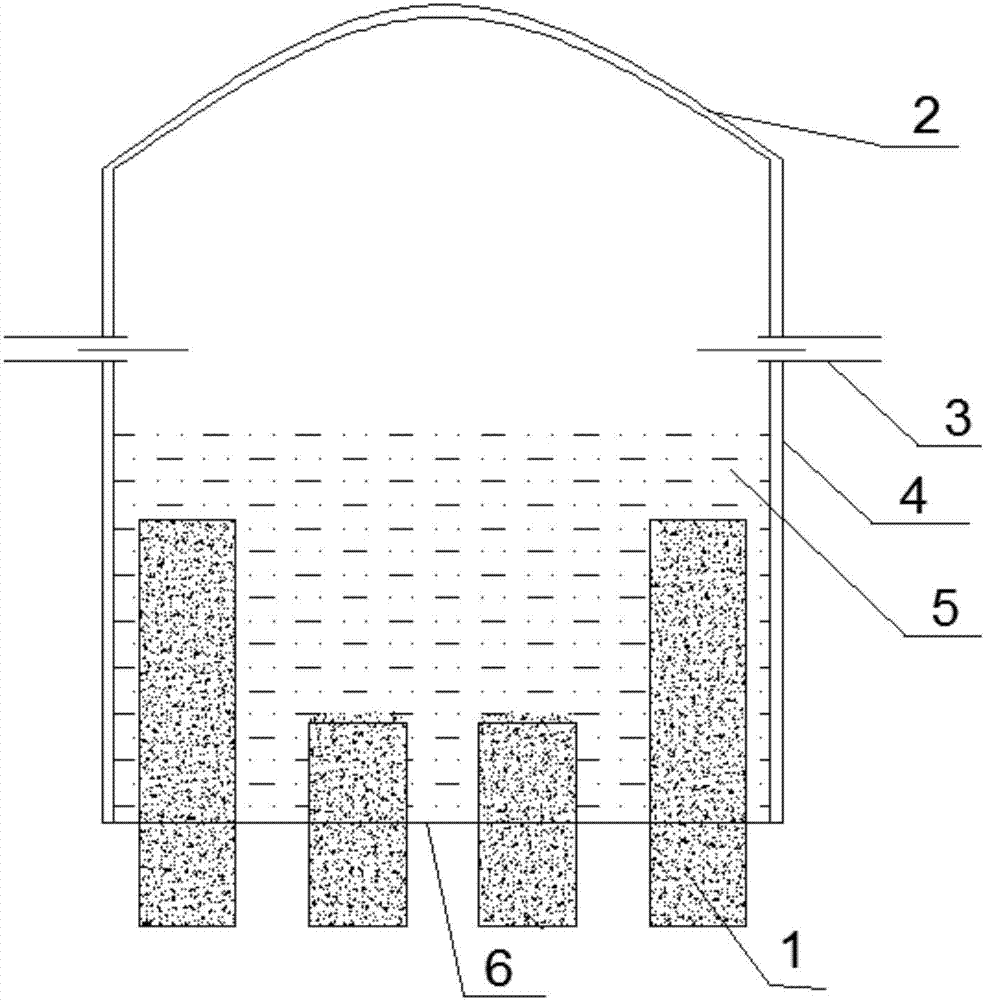

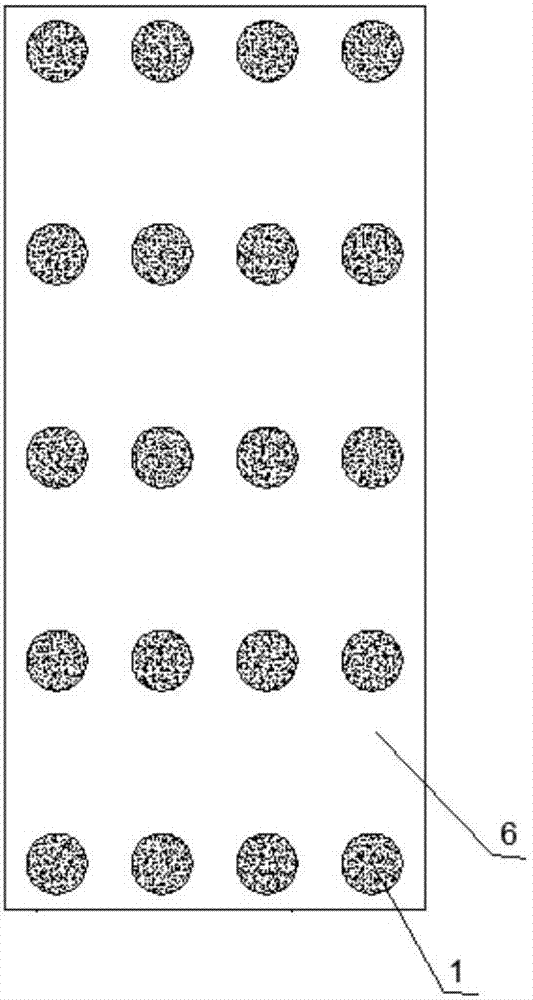

[0023] Such as figure 1 , figure 2 As shown, a kiln device for glass melting and heating includes a kiln 2 for melting glass liquid 5. The kiln 2 includes a kiln pool wall 4 and a pool bottom 6. The side walls of the kiln pool wall 4 are A torch 3 is provided, and a plurality of molybdenum rod electrodes 1 are vertically and evenly distributed on the pool bottom 6 . Wherein the circle of molybdenum rod electrodes close to the furnace pool wall 4 is higher than other molybdenum rod electrodes, and the circle of molybdenum rod electrodes close to the furnace pool wall 4 is lower than the liquid level of the glass liquid 5 .

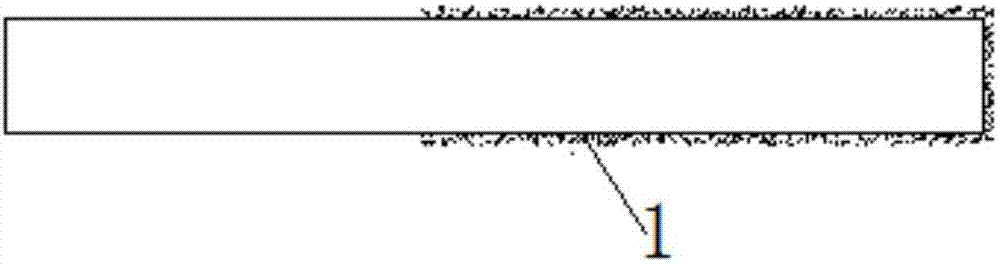

[0024] Such as image 3 As shown, the surface of the molybdenum rod electrode is coated with a platinum alloy layer by blasting method to reduce the erosion of the electrode by glass liquid.

[0025] The kiln pool wall 4 and the pool bottom 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com