Oven with double rotating mechanisms

A double-rotation, oven technology, applied in the direction of baking devices, roasters/barbecue grids, household appliances, etc., can solve the problems of uneven temperature distribution inside the oven cavity, affecting the taste of the effect, and different baking effects, etc., to achieve The effect of improving the uniformity of baking heating and improving the quality and effect of baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

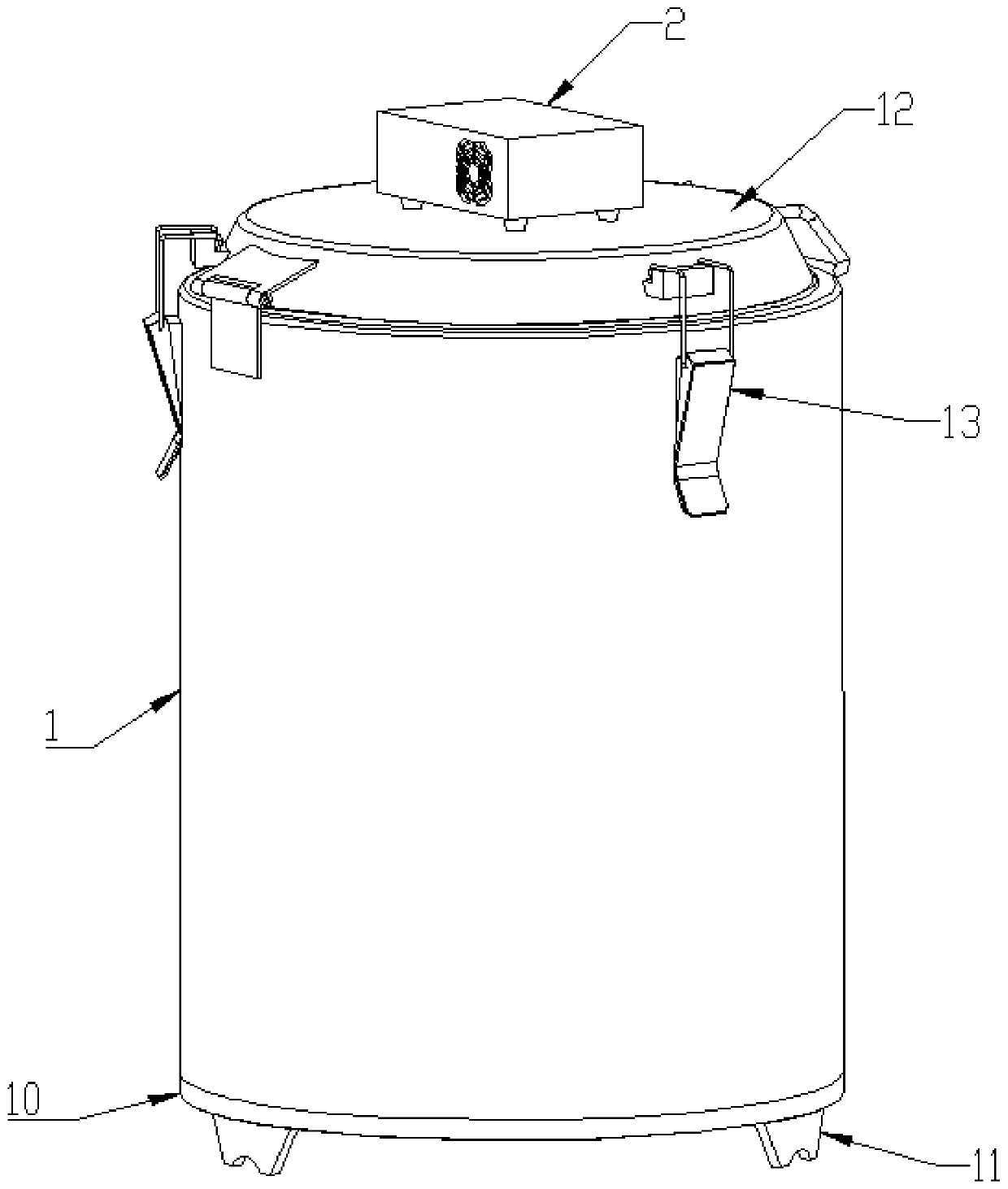

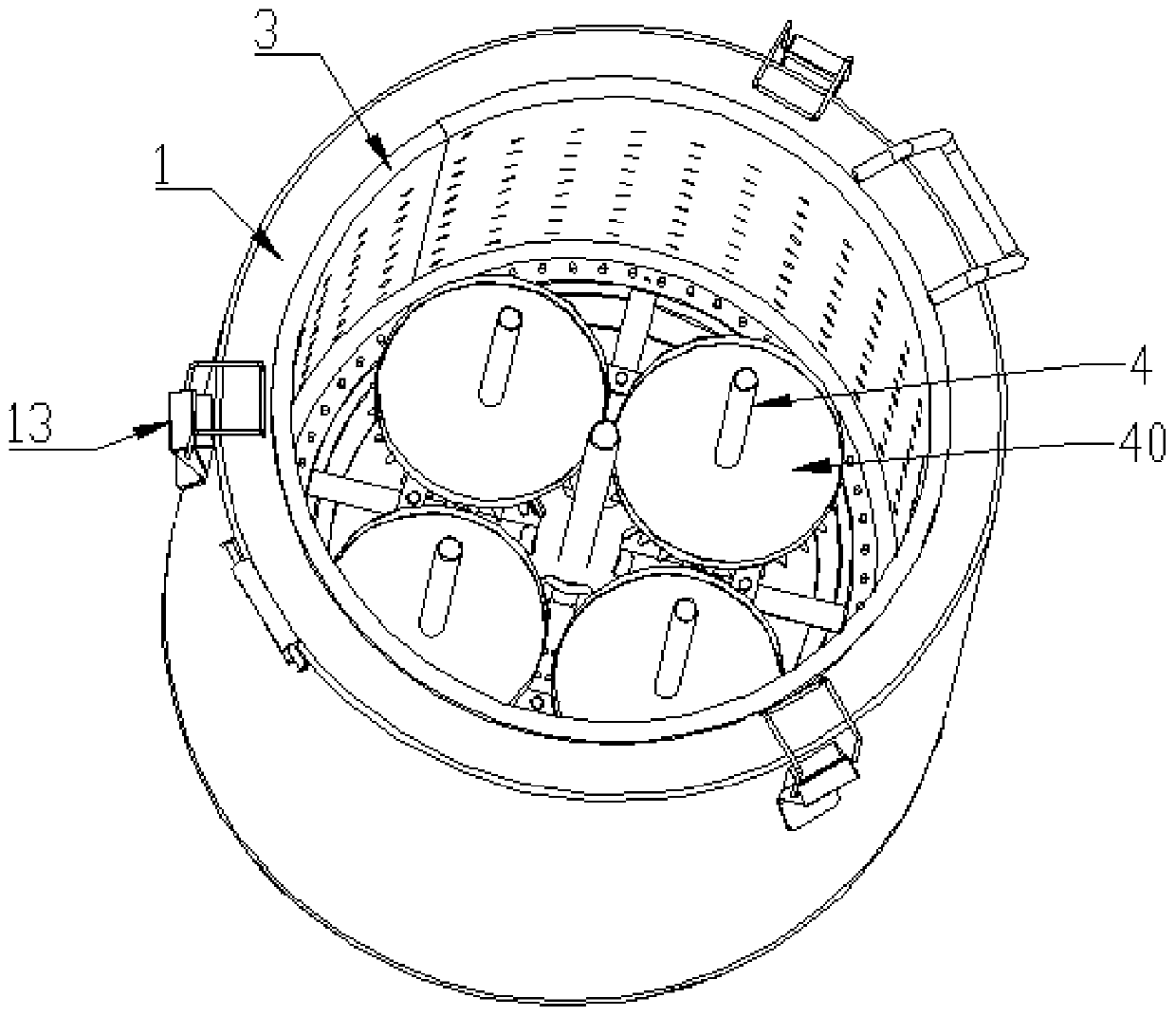

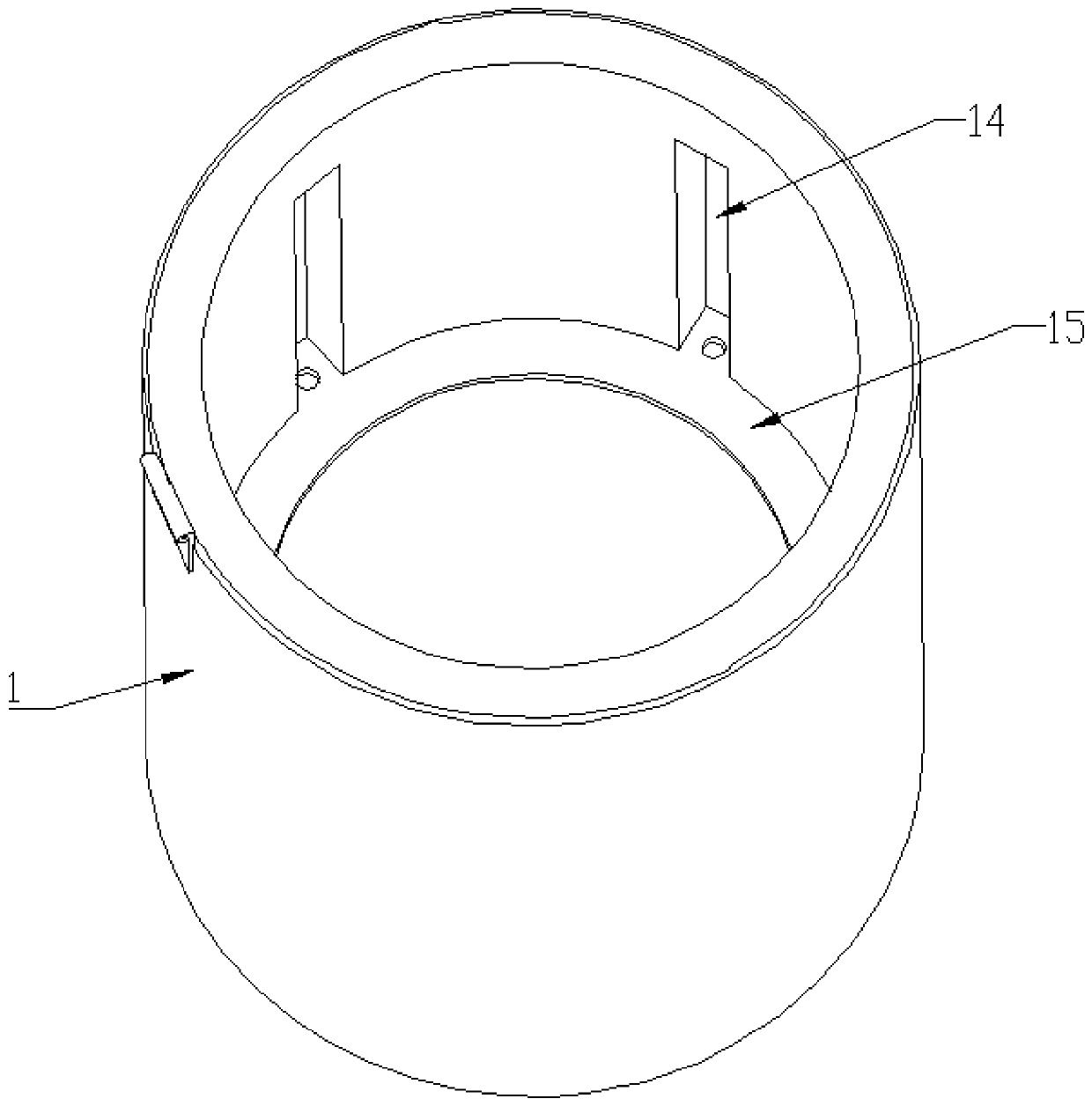

[0025] see Figure 1-7 , in an embodiment of the present invention, an oven with a double rotation mechanism includes an oven cylinder main body 1, a vertical baking cavity is provided inside the oven cylinder main body 1, and a baking cavity is provided in the baking cavity for placing The baking fork 4 of the baked object is provided with a plurality of baking devices around the baking fork 4, and an isolated inner tank 3 for uniform heat is provided between the baking device and the baking cavity. A plurality of baking forks 4 are vertically distributed in the bottom of the baking cavity of the main body 1 of the oven cylinder, and an oil receiving box 40 is arranged on the bottom wall of the baking forks 4. A plurality of baking forks The rod 4 is rotated and fixed on the tray 72 through the rotation rod 73 of the pallet. The inner bottom of the main body of the oven cylinder 1 is provided with a main drive device for driving the rotation of the pallet 72. The bottom end o...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is:

[0033] The top hinged cover of the oven cylinder main body 1 is provided with a furnace cover 12, the bottom of the oven cylinder main body 1 is fixedly supported on the bottom plate 10, and the bottom surface of the bottom plate 10 is supported on the ground by a plurality of supporting feet 11. The furnace cover 12 A power supply box 2 is provided on the top surface of the oven tube main body 1 for supplying power to the internal baking device and the main driving device.

[0034] A plurality of hasps 13 for pressing the furnace cover 12 are installed between the top side wall of the oven cylinder main body 1 and the furnace cover 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com