Chip on film unit

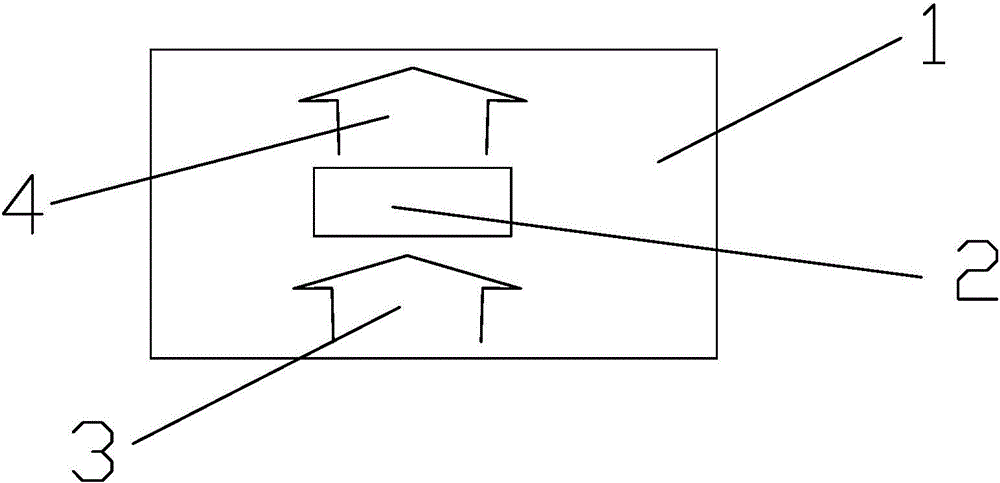

A chip-on-film and driving circuit technology, which is applied in the field of liquid crystal display, can solve the problems of difficulty in heat dissipation and cooling of chip-on-film units, and achieve the effects of reducing the risk of pin breakage, ensuring temperature uniformity, and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

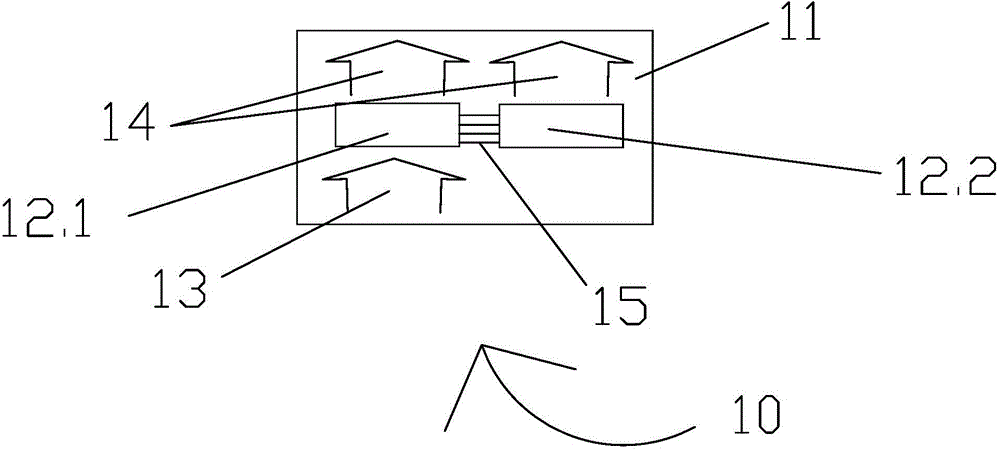

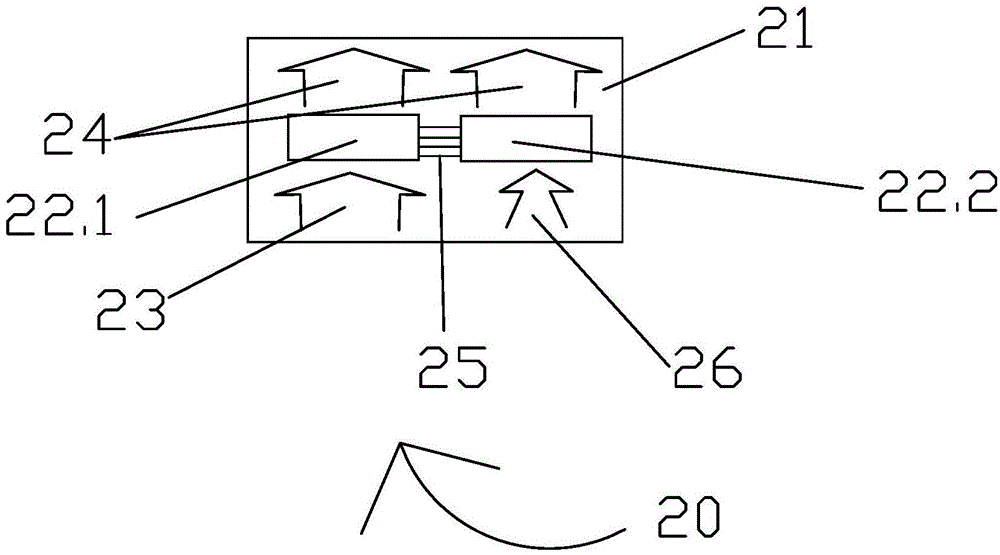

[0024] figure 2 The chip-on-film unit 10 according to the present invention in the first embodiment is shown. pass figure 2 It can be clearly seen that the COF unit 10 first includes a soft dielectric layer 11 . The soft dielectric layer 11 is a flexible carrier made of, for example, polyimide.

[0025] A plurality of pins (not shown in the figure) for inputting signals are arranged on the soft dielectric layer 11 , and the soft dielectric layer 11 can be used as a carrier film for these pins to facilitate tape-and-roll transmission.

[0026] Two drive circuit modules are also arranged on the soft dielectric layer 11, namely a first drive circuit module 12.1 and a second drive circuit module 12.2. There is a certain distance between the first driving circuit module 12.1 and the second driving circuit module 12.2, which can be determined according to the process and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com