Preparation method of anti-freeze agent for marine products

A technology of antifreeze and aquatic products, applied in the direction of food ingredients as antifreeze, food ingredients, food ingredients containing oligosaccharides, etc., can solve the problems of high sweetness and calories, affecting product flavor and nutritional value, and achieve sweetness Low taste and heat, avoid open chain denaturation, and enhance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

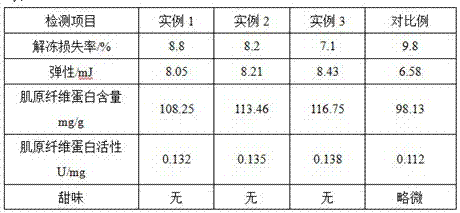

Examples

example 1

[0022] First, wash the red algae with water and put them into a beater for beating, then add 2.8L of deionized water, mix them evenly, place them in a flash extractor, extract at 55°C for 2min, and then transfer them to a centrifuge at 6000r / Centrifuge for 15 min, collect the extract and precipitate; repeat the extraction of the precipitate twice, collect and combine the supernatant, put the combined supernatant in a flash concentrator, and concentrate to 8% of the volume of the original solution to obtain a concentrated solution , then add the concentrated solution into 600mL of absolute ethanol, stir at 300r / min for 1h, let it stand for 20h, transfer it to a centrifuge, and centrifuge at 6000r / min for 15min, collect the precipitate to obtain the crude compound polysaccharide; weigh 1g of the crude product Add the complex polysaccharide to 20mL of deionized water, stir at 300r / min for 10min, then add 10mL of isopropanol, stir at 300r / min for 10min, then add 35mL of 20% sodium...

example 2

[0024] First, wash the sargassum algae and put them into a beater for beating, then add 3.0L of deionized water, mix well, place in a flash extractor, extract at 55°C for 2min, and then transfer to a centrifuge for 7000r / Centrifuge for 18 min, collect the extract and precipitate; repeat the extraction of the precipitate twice, collect and combine the supernatant, put the combined supernatant in a flash concentrator, and concentrate to 9% of the volume of the original solution to obtain a concentrated solution , then add the concentrated solution into 700mL of absolute ethanol, stir at 300r / min for 1h, let it stand for 22h, transfer it to a centrifuge, and centrifuge at 7000r / min for 18min, collect the precipitate to obtain the crude compound polysaccharide; weigh 1g of the crude product Add the complex polysaccharide to 30mL of deionized water, stir at 350r / min for 15min, then add 11mL of isopropanol, stir at 350r / min for 15min, then add 40mL of 20% sodium hydroxide solution, ...

example 3

[0026] First, wash the spirulina with water and put it into a beater for beating, then add 3.0L deionized water, mix evenly, place it in a flash extractor, extract at 60°C for 3min, and then transfer it to a centrifuge for 8000r / Centrifuge for 20 min, collect the extract and precipitate; repeat the extraction of the precipitate 3 times, collect and combine the supernatant, put the combined supernatant in a flash concentrator, concentrate to 10% of the volume of the original solution, and obtain a concentrated solution , then add the concentrated solution into 800mL of absolute ethanol, stir at 400r / min for 2h, let it stand for 24h, transfer it to a centrifuge, and centrifuge at 8000r / min for 20min, collect the precipitate, and obtain the crude compound polysaccharide; weigh 2g of the crude product Add the complex polysaccharide to 40mL of deionized water, stir at 400r / min for 20min, then add 12mL of isopropanol, stir at 400r / min for 20min, then add 42mL of 20% sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com