Energy recovery type intelligent full fresh air processing unit

An energy recovery and intelligent technology, applied in the ventilation and heating energy recovery systems, heat recovery systems, ventilation systems, etc., can solve the problems of low equipment efficiency, shortened service life, high fresh air pressure, etc., to achieve increased energy consumption, The effect of reducing energy consumption and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

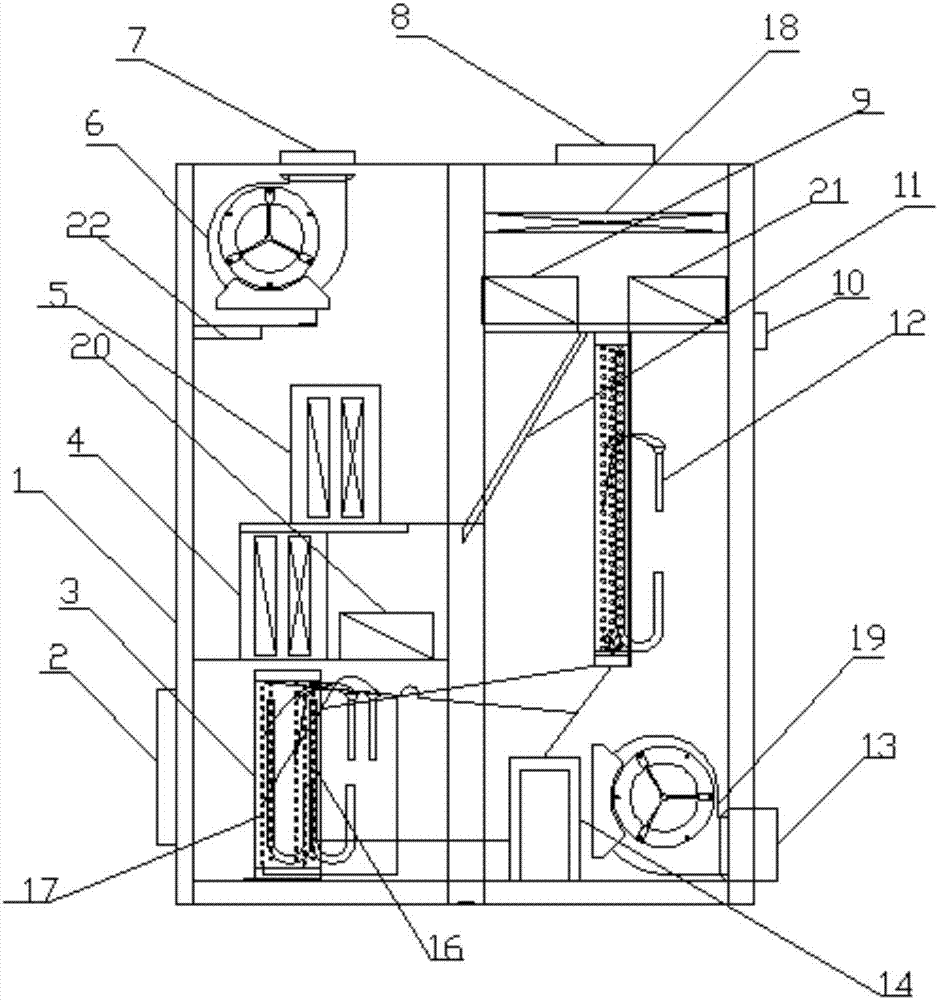

[0027] like figure 1 As shown, it is an embodiment of the energy recovery type intelligent fresh air processing unit of the present invention, including a cabinet body 1, the cabinet body 1 is a cuboid, one end is provided with a fresh air inlet 2, and its opposite end is provided with a return air outlet 13, the cabinet body The upper end is provided with parallel fresh air outlet 7 and return air inlet 8 . The fresh air outlet 7 and the return air inlet 8 respectively correspond to the air supply side and the exhaust air side in the cabinet. The fresh air outlet 7 and the exhaust air outlet 13 are respectively provided with a first volute fan 6, which can send fresh air or return air out from the corresponding outlets. The air supply side of the cabinet body 1 is provided with an evaporative condenser 3, a first tuyere 20, a first primary filter 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com