A kind of porous fiber material carrier and its preparation method and its application in treating waste water

A technology of porous fiber and fiber material, applied in the field of porous fiber material carrier and its preparation, which can solve the problems of poor treatment effect and long start-up period of wastewater treatment, and achieve good mass transfer performance, stable reaction, and favorable discharge treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

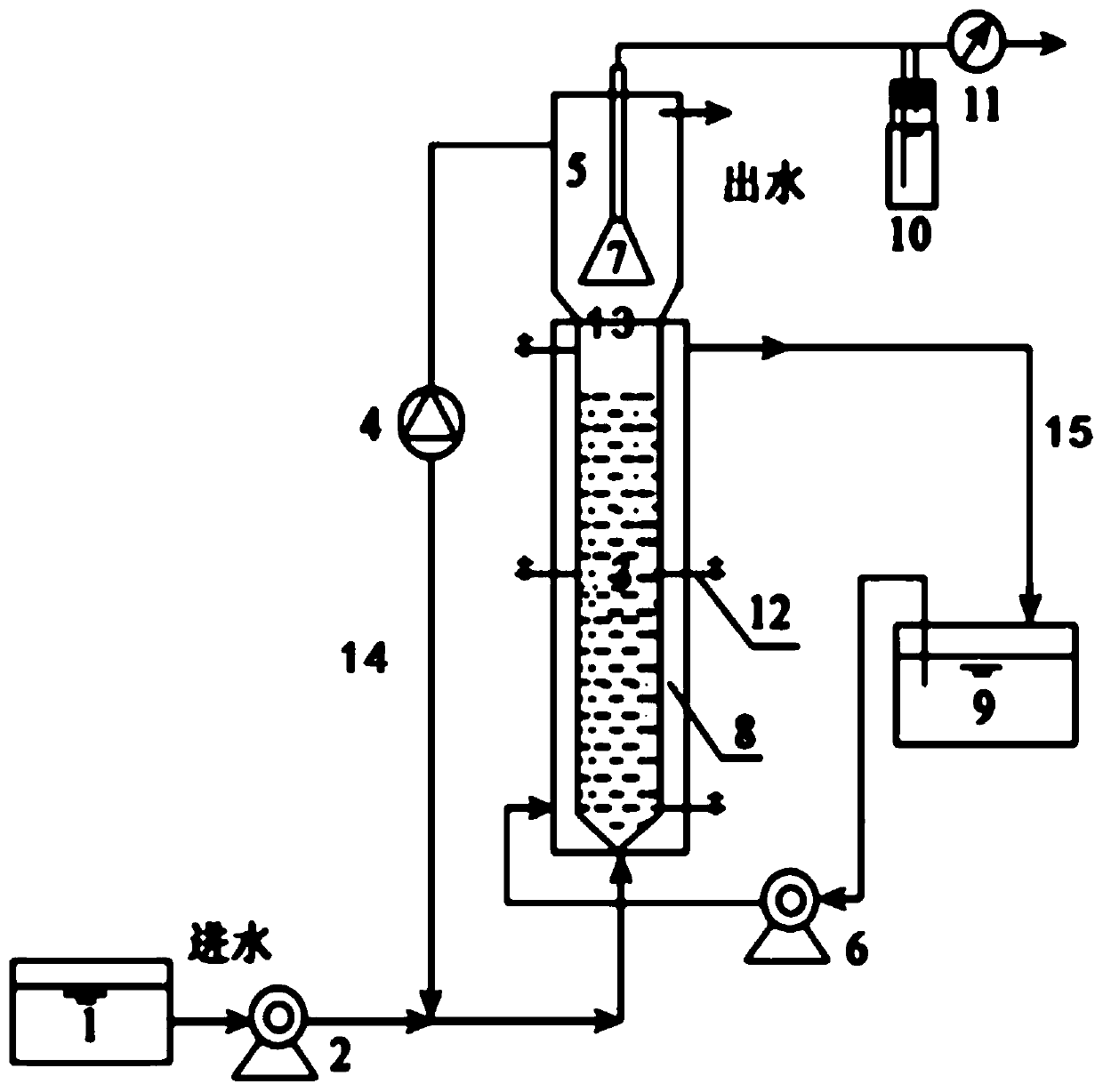

Method used

Image

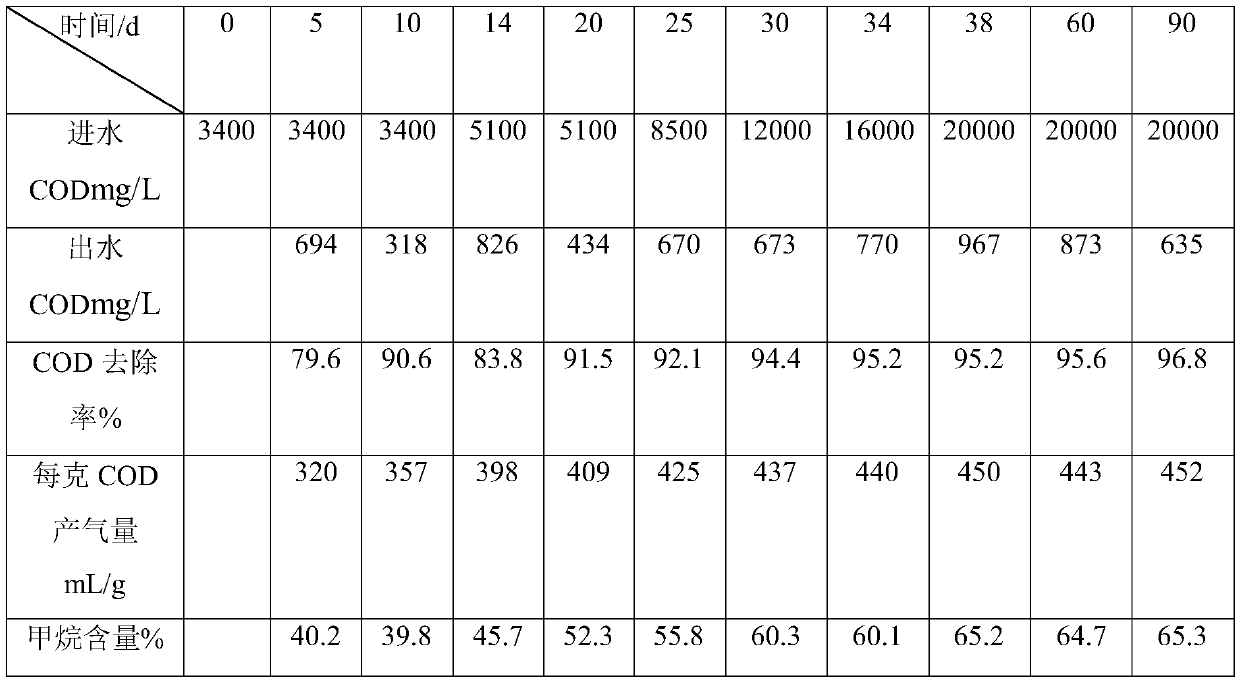

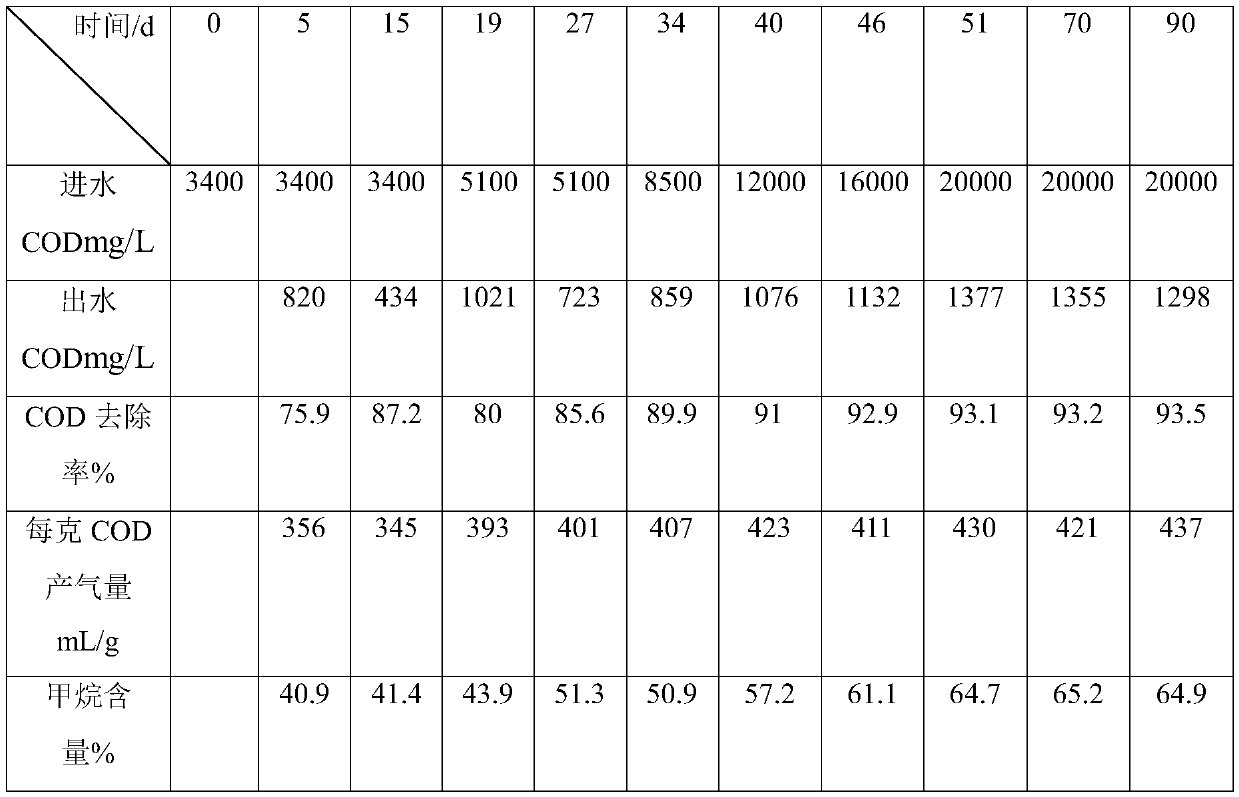

Examples

Embodiment 1

[0033] Wash the polyethylene fiber in pure water for 2 hours, then soak it in more than 95% alcohol for 6 hours, then rinse it with alcohol, dry it, and crush it. It is prepared by 3D printing technology. It is short cylindrical and has a density of 0.95g / cm 3 , the aperture is 12mm, the diameter is 25mm, the height is 10mm, and the porosity is 70%.

Embodiment 2

[0035] Wash the polyethylene fiber and polyether polyol in pure water for 2 hours, then soak in 95% alcohol for 6 hours, then rinse with alcohol, dry, pulverize, mix completely according to the mass ratio of 9:1, pass Prepared by 3D printing technology, low cylindrical shape, density 0.96g / cm 3 , the aperture is 15mm, the diameter is 30mm, the height is 10mm, and the porosity is 70%.

Embodiment 3

[0037] Wash the polyurethane fibers and polyvinyl alcohol fibers in pure water for 2 hours, and then soak them in more than 95% alcohol for 6 hours. Prepared by printing technology, cube, density 0.9g / cm 3 , the aperture is 3mm, the side length is 15mm, and the porosity is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com