Environment-friendly and waterproof high-intensity bathroom panel and preparing method thereof

A high-strength board technology, applied in the field of environmental protection waterproof high-strength bathroom boards and its production, can solve the problems of cumbersome production process, single color, non-pollution resistance, etc., and achieve the effect of low process difficulty, simple production equipment and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

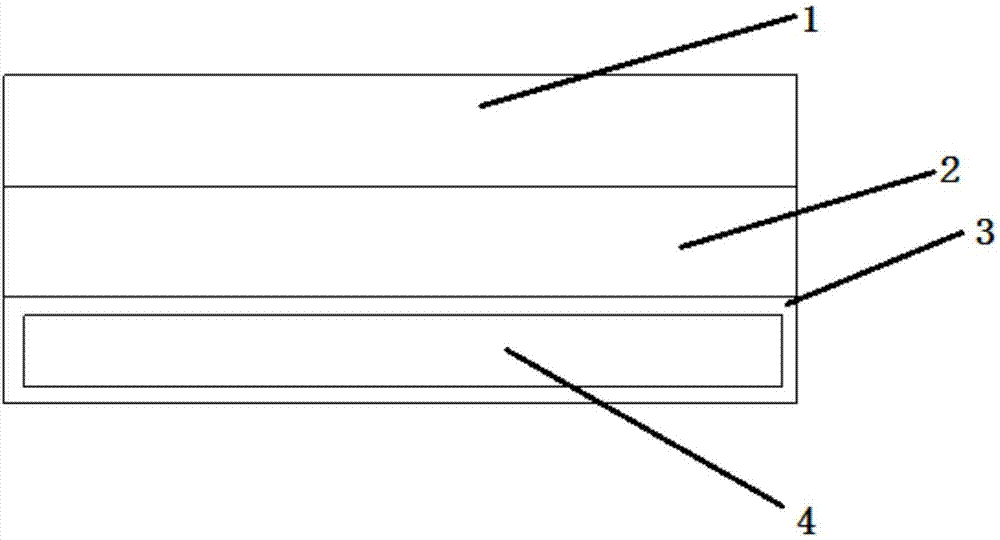

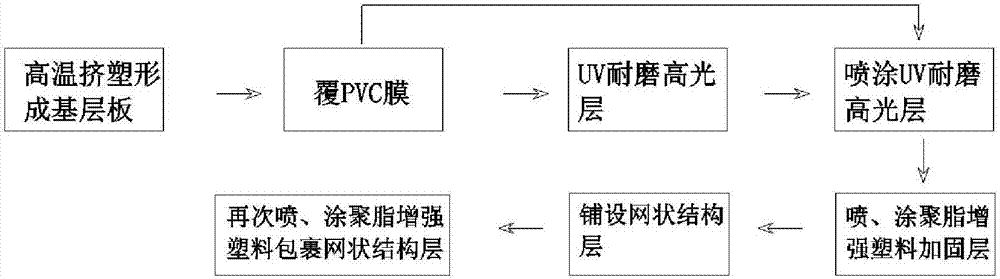

Embodiment 1

[0038] Use extrusion equipment to extrude 3mm thick PVC stone-plastic board, the PVC stone-plastic board and the PVC film in the surface layer are integrated hot-melt hot-melt, and the side of the PVC stone-plastic board is sprayed with a 2mm thick 191 Pro benzene A mixture of saturated polyester resin and glass reinforced fiber. Before the mixture is cured, a grid-like keel is laid. The grid-like keel is composed of a galvanized square tube with a cross-sectional inner side of 20mm and a thickness of 1.5mm. Two adjacent galvanized square pipes The distance between the steel pipes is 250mm; then spray 1.5mm thick 191 Pro benzene unsaturated polyester resin and glass reinforced fiber mixture to wrap all the grid-shaped keels, and then cure the unformed plate at 25 degrees Celsius for 1 hour , Cover the front with a protective film to obtain the finished sheet.

Embodiment 2

[0040] Use the extrusion equipment to extrude the 3.5mm thick PVC stone plastic board, the PVC stone plastic board and the PVC film in the surface layer are integrated hot-melt and hot, and the side of the PVC film that is not hot is cured by UV ultraviolet light. The unheated PVC film is sprayed with a 2mm thick mixture of 191 Pro benzene unsaturated polyester resin and glass reinforced fiber. After curing, a grid-like keel is laid. The grid-like keel is 20mm in cross section and 2mm thick. Composed of galvanized square pipes, the distance between two adjacent galvanized square steel pipes is 250mm; then 1.5mm thick 196 flame-retardant unsaturated polyester resin and glass reinforced fiber mixture are sprayed to make the grid-like keel Wrap all, and then cure the unformed sheet at 20 degrees Celsius for 2 hours, and cover the front with a protective film to obtain the finished sheet.

Embodiment 3

[0042] Use extrusion equipment to extrude the 3.5mm thick PVC stone-plastic board, spray 2mm thick 2608 xylene unsaturated polyester resin and glass reinforced fiber mixture on the back of the PVC stone-plastic board, and pave the grid-like keel after curing. The keel is composed of a galvanized square pipe with a cross-sectional inner side of 20mm and a thickness of 2mm. The distance between two adjacent galvanized square steel pipes is 250mm; and 1.5mm thick 2608 flame-retardant xylene unsaturated The mixture of polyester resin and glass reinforcing fiber wraps all the grid-like keels, and then the unformed sheet is cured at 20 degrees Celsius for 2 hours. The front side of the base layer is vacuum-heated with PVC film, and the unheated side of the PVC film is UV-rayed Light curing treatment, the front surface is covered with a finished protective film to obtain a finished board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com