In-mold integral pattern forming technology for silica gel watch band with large radian surface

A pattern forming and crafting technology, applied in watch straps, bracelets, clothing, etc., can solve the problems of unrealizable products, small limitations of in-mold products, low efficiency, etc., to save production costs, save production cycles, and perfectly combine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

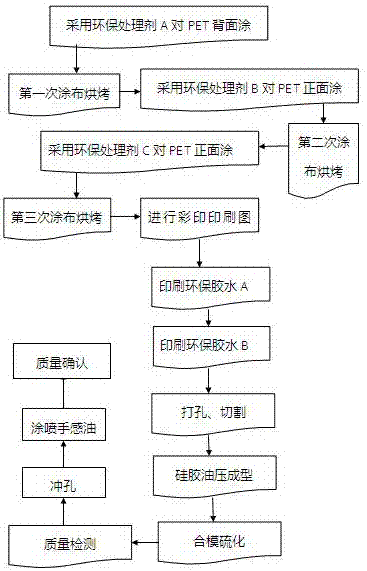

Image

Examples

Embodiment 1

[0055] Use environmentally friendly treatment agent A to coat the back of PET. The thickness of the coating on the back of PET is 1.5μm. The components of the environmentally friendly treatment agent A by mass percentage are: coupling agent 3%, electrostatic agent 5%, curing agent 2% , The balance is methyl vinyl; the first coating and baking, the coating speed during baking is 50m / min, the first coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent B is used on the front of the PET The coating thickness of the PET front coating is 1.5μm. The components of the environmental protection treatment agent B according to mass percentage are: coupling agent 5%, retarding agent 8%, curing agent 7%, and the balance is methyl vinyl ; The second coating and baking, the coating speed during baking is 50m / min, the second coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent C is used to coat the PET front, and the envi...

Embodiment 2

[0058] Use environmentally friendly treatment agent A to coat the back of PET. The thickness of the coating on the back of PET is 1.5μm. The components of the environmentally friendly treatment agent A by mass percentage are: coupling agent 3%, electrostatic agent 5%, curing agent 2% , The balance is methyl vinyl; the first coating and baking, the coating speed during baking is 50m / min, the first coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent B is used on the front of the PET The coating thickness of the PET front coating is 1.5μm. The components of the environmental protection treatment agent B according to mass percentage are: coupling agent 5%, retarding agent 8%, curing agent 7%, and the balance is methyl vinyl ; The second coating and baking, the coating speed during baking is 50m / min, and the second coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent C is used to coat the PET surface, and th...

Embodiment 3

[0061] Use environmentally friendly treatment agent A to coat the back of PET. The thickness of the coating on the back of PET is 1.5μm. The components of the environmentally friendly treatment agent A by mass percentage are: coupling agent 3%, electrostatic agent 5%, curing agent 2% , The balance is methyl vinyl; the first coating and baking, the coating speed during baking is 50m / min, the first coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent B is used on the front of the PET The coating thickness of the PET front coating is 1.5μm. The components of the environmental protection treatment agent B according to mass percentage are: coupling agent 5%, retarding agent 8%, curing agent 7%, and the balance is methyl vinyl ; The second coating and baking, the coating speed during baking is 50m / min, and the second coating and baking temperature is 115℃ / 15min; the environmental protection treatment agent C is used to coat the PET surface, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com