Car painting turnover frame

A technology for flipping racks and automobiles, which is applied in the direction of spraying devices, etc. It can solve the problems of poor lifting and lowering of support rods, cumbersome adjustment of paint spraying racks, and easy self-swinging, etc., so as to avoid hard friction, improve fixing stability, and improve ride comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

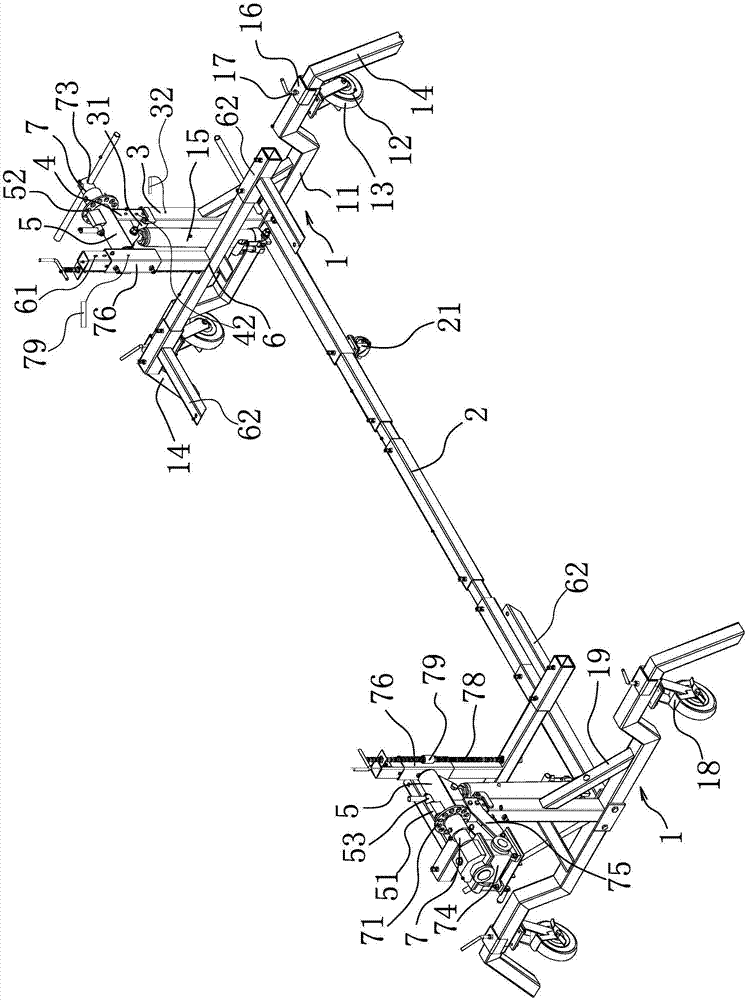

[0037] Such as figure 1 As shown, the car paint overturning frame includes two symmetrically arranged main supports 1 and is connected by a connecting rod 2 between the two main supports 1. The connecting rod 2 is a telescopic connecting rod, and the connecting rod 2 is connected with at least one auxiliary wheel 21 .

[0038] The main support 1 includes a few-shaped pipe body 11, and the two ends of the several-shaped pipe body 11 are connected with traveling wheels 12 respectively. The traveling wheels 12 are made of metal materials, which improve the load-bearing performance. A plastic sleeve 13 is set on the sleeve, and support feet 14 are connected to the two ends of the several-shaped pipe body 11 through a detachable connection structure, and when the plastic sleeve 13 deforms in the radial direction, the support feet 14 are in contact with the ground.

[0039] Walking wheel 12 is hinged with pedal brake frame 18, and pedal brake frame 18 realizes braking after contact...

Embodiment 2

[0069] Such as Figure 7 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, so we won’t repeat them here. The difference lies in:

[0070] The end of each rotating shaft 7 away from the lifting frame 6 is respectively provided with a turning handle insertion hole 73 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com