Conveying device for stamping surface leather of ball sports goods

A technology for sporting goods and conveying devices, which is applied in metal processing and other directions, and can solve problems such as rough cutting surface, rough leather structure, and the influence of leather block processing efficiency, so as to reduce the contact area, ensure stability, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

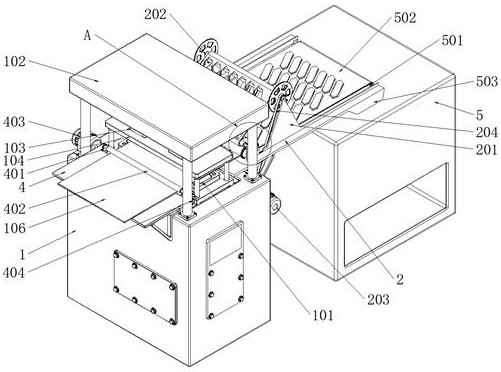

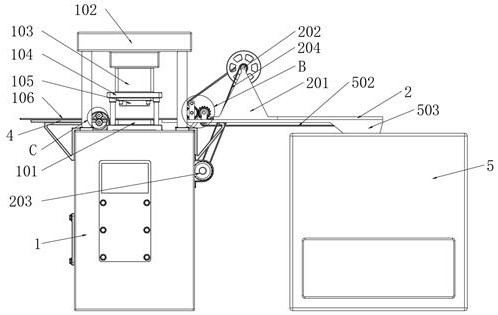

[0047] see Figure 1-Figure 10 , a conveying device for punching leather on the surface of ball sporting goods, comprising a main body 1, the top middle position of the main body 1 is fixedly covered with a punching table 101, the top of the main body 1 is fixedly connected with a top frame 102 through a pillar, and the top A hydraulic telescopic rod 103 is fixedly installed at the bottom of the frame 102, a connecting plate 104 is fixedly installed on the telescopic end of the hydraulic telescopic rod 103, and a plurality of cutting dies 105 corresponding to the punching table 101 are fixedly arranged at the bottom of the connecting plate 104, A leather material 106 runs through the top of the punching table 101;

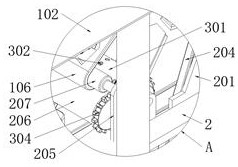

[0048] The top right side of the main body 1 is fixedly installed with a horizontally arranged discharging platform 2 , the left end of the discharging platform 2 is fixedly installed with a bracket 2 205 , and the inner part of the bracket two 205 is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com